Gary W. Graley

“Imagination is more important than knowledge"

Knifemaker / Craftsman / Service Provider

- Joined

- Mar 2, 1999

- Messages

- 26,365

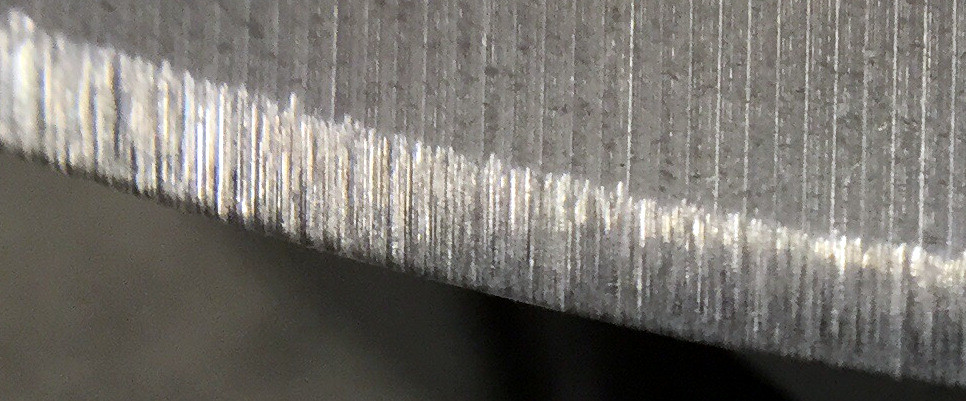

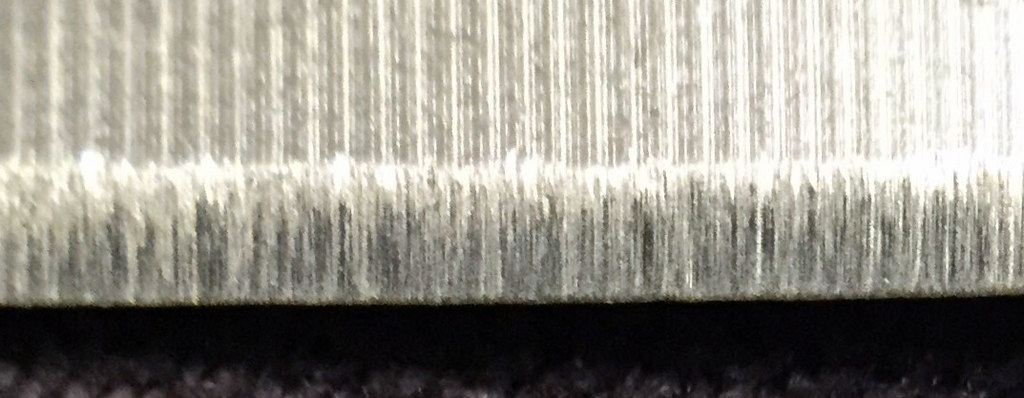

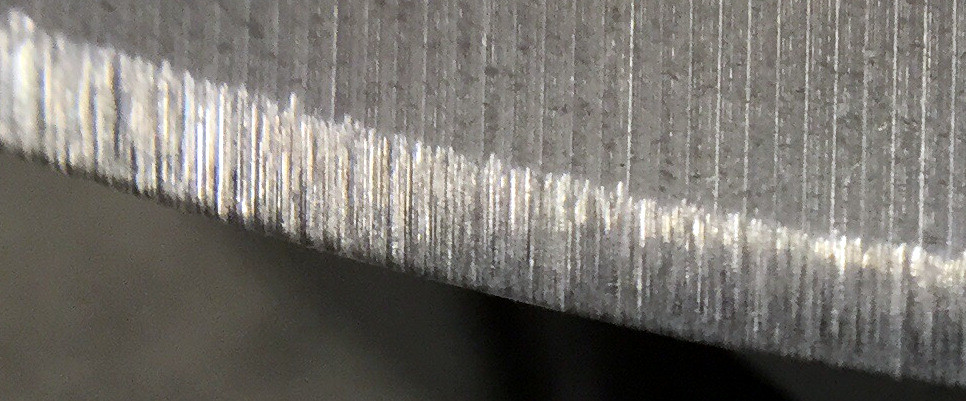

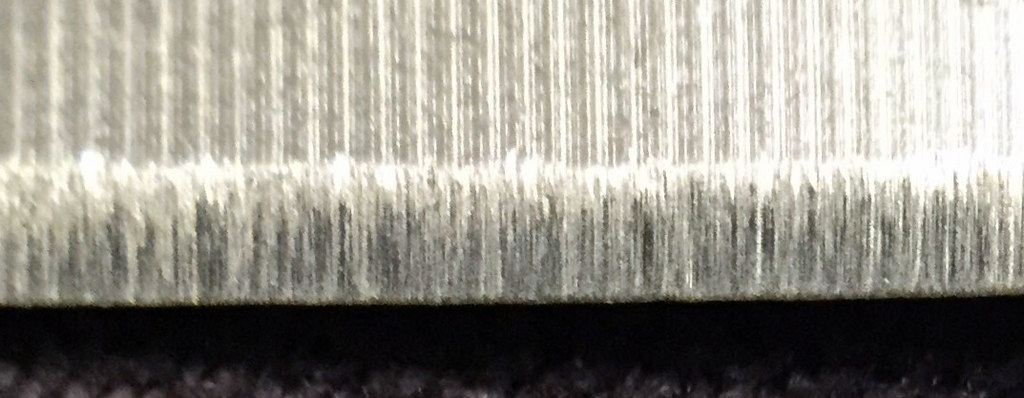

On my new Benchmade 590 Boost, it's edge is quite toothy, which I like and want to try to maintain that, but, not sure just how to do that as I always head towards a more polished edge bevel.

My guess is to stop at a much lower grit, say 400 and not strop it too much if at all ?

Here's some shots of the edge bevel, you can see the scratch pattern is more perpendicular to the edge, which makes it cut well in either direction of the cut.

BM590-_edge by GaryWGraley, on Flickr

BM590-_edge by GaryWGraley, on Flickr

BM590_edge by GaryWGraley, on Flickr

BM590_edge by GaryWGraley, on Flickr

I am also guessing that Benchmade uses belts to put the final edge on their blades, is there any youtube video showing how they do their sharpening?

All in all, I'm still really liking this folder a great deal.

IMG_6655 by GaryWGraley, on Flickr

IMG_6655 by GaryWGraley, on Flickr

G2

My guess is to stop at a much lower grit, say 400 and not strop it too much if at all ?

Here's some shots of the edge bevel, you can see the scratch pattern is more perpendicular to the edge, which makes it cut well in either direction of the cut.

BM590-_edge by GaryWGraley, on Flickr

BM590-_edge by GaryWGraley, on Flickr BM590_edge by GaryWGraley, on Flickr

BM590_edge by GaryWGraley, on FlickrI am also guessing that Benchmade uses belts to put the final edge on their blades, is there any youtube video showing how they do their sharpening?

All in all, I'm still really liking this folder a great deal.

IMG_6655 by GaryWGraley, on Flickr

IMG_6655 by GaryWGraley, on FlickrG2