- Joined

- Jul 31, 2017

- Messages

- 1,356

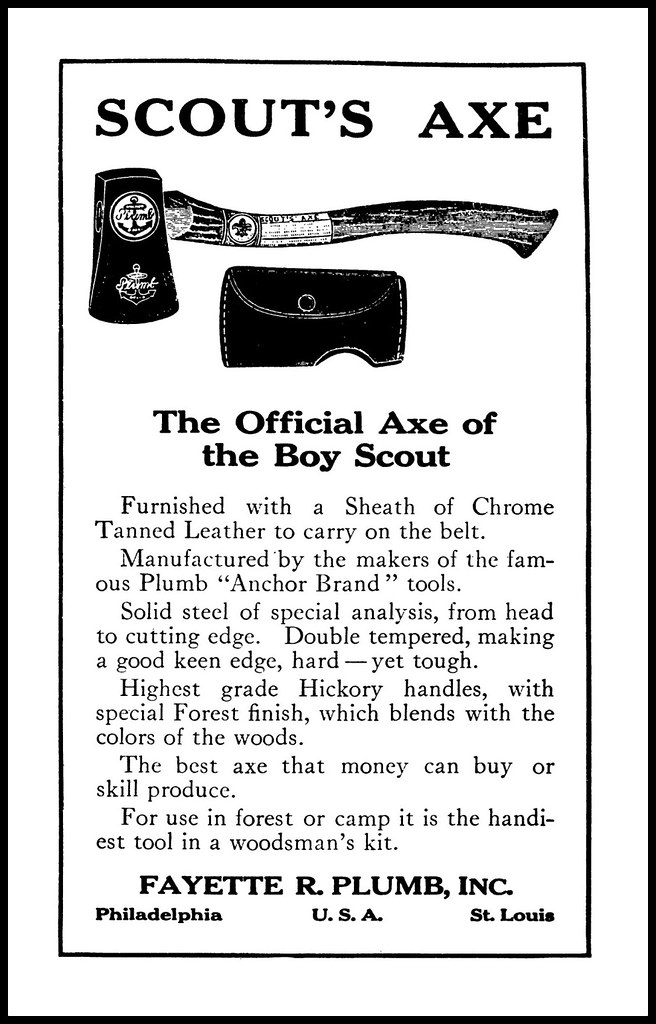

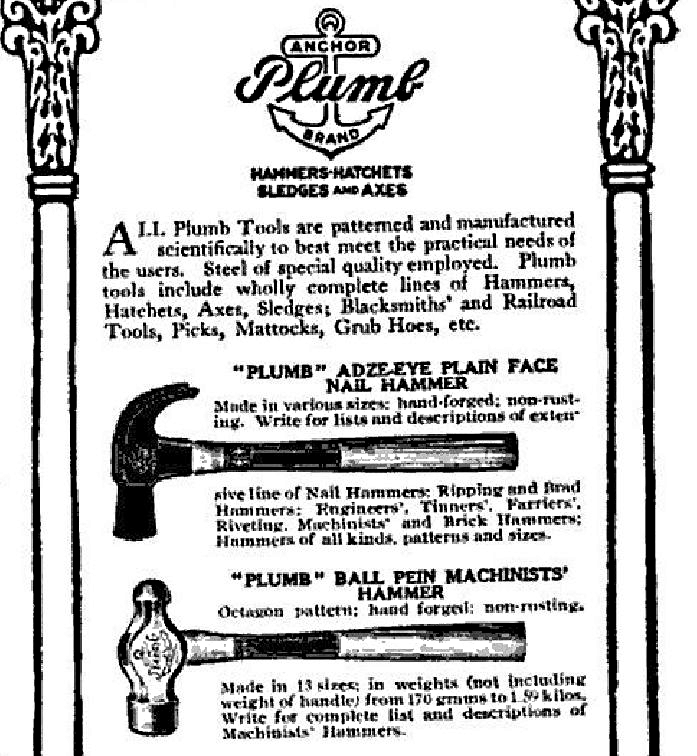

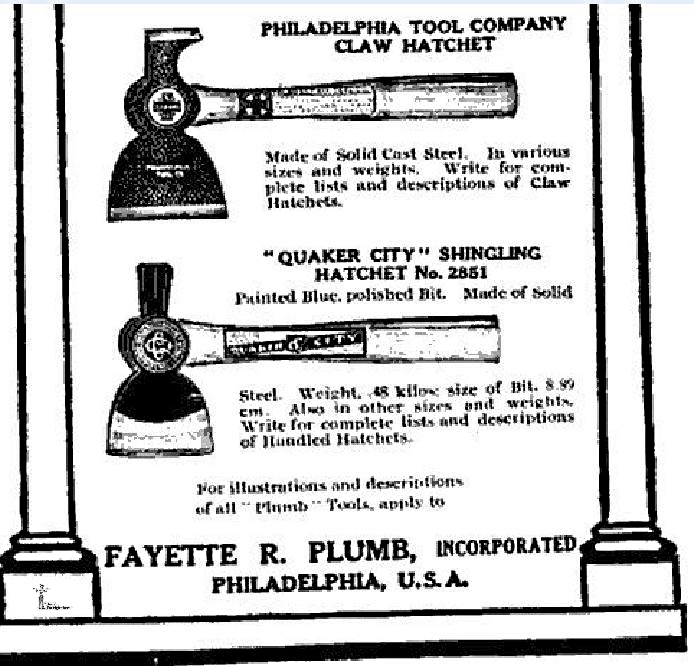

Thanks Garry3. Once You mentioned that diamond mark points to Plumb (before 1960 Australia export???) I searched for Plumb Dayton pics ..... it really looks like one. https://www.bladeforums.com/threads/shes-a-big-girl-plumb.999970/Handle looks like maybe its been stained red like the Plumb handles? I would have thought that maybe some one switched heads on an old Plumb house axe handle, they did have a full size eye but you have that triangle stamp on that head also. Its hard to say just what it is...

https://www.bladeforums.com/threads/plumb-manufacturing-thread.1066763/#post-12177851

IMG_20170816_121804

IMG_20170816_121804 IMG_20170816_121828

IMG_20170816_121828

IMG_20170816_171617

IMG_20170816_171617