Gary W. Graley

“Imagination is more important than knowledge"

Knifemaker / Craftsman / Service Provider

- Joined

- Mar 2, 1999

- Messages

- 26,345

Since this has become a Sticky, thank the Mod's

I'll edit this first post with a listing that was in the Good Bad And Ugly feed back area

There be a lot of talented gents when it comes to leather here on the forums;

Here is a list of those that are Recommended to choose from

These guys, not in any particular order, all have a passion for leather work

so this thread can be a handy reference for future folks when they search

for someone to help with their leather needs...And please note, I only posted

those that participate in BladeForums, there are others but are not active members

so I limited the list to those in our town, so to speak

Edited to add that Dwayne Puckett, aka Leatherman, started a new thread which is also a sticky

that contains posts from leathersmiths seen hmm the old link is broken with this new software, here's a fresh link to that page https://www.bladeforums.com/threads/sheath-makers-and-such-of-blade-forums.838494/

Sandy Morrissey known on the forums as Swivelknife aka helmar45789

His Email no web site that I know of

Paul Long known on the forums as sheathmaker

his Email no web site that I know of

Mike Bartol known on the forums as MtMike

his Email

Mike has a foto time where you can view some of his work Here

Dave Abramson known on the forums as Lifter4Him

His Email

His Web page

Chuck Burrows, known on the forums as Wild Rose

His Email

His Web page

Ken Collucci's Email,

His Web page

Dwayne, known on the forum as leatherman

His Email

His Web page

Mike Tea, known on the forums as Zozzie

(removed his old email addy)

Mike's a citizen of Canada as well as a noted bicyclist

Please note, Mike Tea's sheath making has stopped for a while, he replied

on a thread on August 2, 2008, but you can search the various threads

and see some of his fine work and that may inspire you to try your hands

at his style of sheaths, very beautiful workmanship.

Vess, known on the forums as Vess...he also hails from Canada...

His Email

His Web page

Ed Alpern, known on the forums as fasteddie, Ed is an up and comer, keep an eye on this fella!

His Email

no web page yet, but soon.

***********************************************************************************

And now back to the thread where it began;

Hey folks, traveling a lot lately, but now home for a bit so figured I'd add some

of what I do, there are many ways to skin a cow, this is just one of those stories

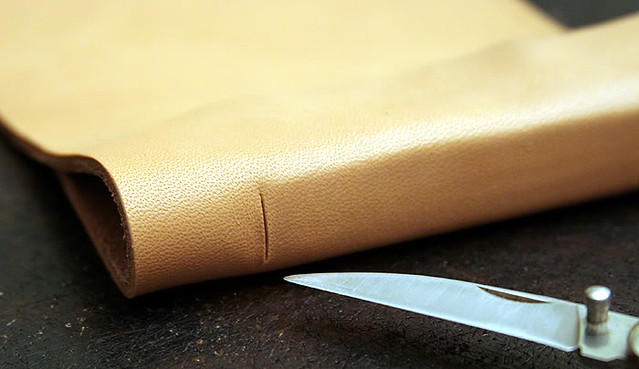

First you start with this;

madcow by GaryWGraley, on Flickr

madcow by GaryWGraley, on Flickr

well, at least part of it I buy my leather from Wickett & Craig they are out of PA

I buy what's called Shoulder leather, very tight grain, the good stuff

For Vertical sheaths I use 7/8 oz leather, depending on the size

if it's a very small knife, I'll use the 6/7 oz

For the top sections of the horizontal sheaths, I use 6/7 oz leather

for the layer beneath the knife and the belt loop section I use

a little thicker, 7/8 oz leather

And yes, it is a little thick to form, it is stubborn stuff and always wants

to retract back to it's original flat shape, so you need to KEEP working the

leather repeatedly as it goes from wet to it's dry state, that's key to making

the leather retain it's shape.

Tools, mostly from Tandy back in the day, now my tools are quite aged

much like the user, but I hear tell that Tandy is making a come back in

leather, but see this Link to Tandy for their current offerings.

if you have a tax id number, Weaver Leather also provides nice leather as well as a host of tools.

Tools;

Knife, of course a knife, this one is a Custom by a friend, Tony Bose, I made

a special request and he honored me with this gift of a small carving knife, I don't

know of another knife maker that is as kind a man as he is, thanks again Tony!

Sucker is Sharp! Link

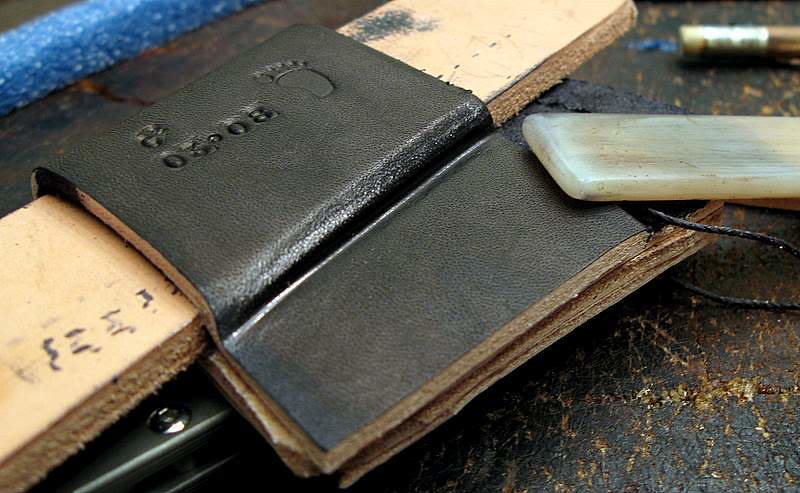

Bone folder, used to do the majority of my shaping around the knife

I use the SQUARE end to do my shaping, there is a rounded piece that you pull off and

it shows the square end, also if there are any maker marks on the tool, sand that down

so it's VERY smooth, don't want that scratching your leather.

The pointed end of the bone folder I use to burnish the crease that I put at the opening

of the sheaths once it's about dry, I just run that along in the groove, VERY carefully as you

can slip out of the thin groove pretty easily, and that tip will deepen and burnish the groove for you nicely.

IMG_0490 by GaryWGraley, on Flickr

IMG_0490 by GaryWGraley, on Flickr

Stitching Prongs, I have three that I use, a 4 prong for long stretches

3 prong for some curves and a 'custom' 2 prong for going into tight quarters

IMG_0499 by GaryWGraley, on Flickr

IMG_0499 by GaryWGraley, on Flickr

Mallet for said stitching prongs and embossings

IMG_0505 by GaryWGraley, on Flickr

IMG_0505 by GaryWGraley, on Flickr

Ruler and pencil, nuff said

IMG_0500 by GaryWGraley, on Flickr

IMG_0500 by GaryWGraley, on Flickr

Groover, I use this to place a groove near the openings of the sheath, to me it

provides a more finished look to the sheath; Link

Edge beveler/cutter, this takes off a sharp corner of the leather, comes in

several sizes Link

Awl and custom awl made from a small screwdriver, used to hammer through thick

layers of leather to prepare for sewing, the regular awl I use to start the thread

holes and to enlarge the last few holes for the ending of the sewing;

Link

Awl-n-Awl sewing tool, some guys use the two needle system, I like this method for my sheaths;

IMG_0495 by GaryWGraley, on Flickr

IMG_0495 by GaryWGraley, on Flickr

Thread I use Link

Gunk, well, sort of, Oil dye, Gum, and Atom balm wax EDITED to say that I NO LONGER use the Atom Balm wax but now use a leather preservative that is more like a paste, works better and protects a lot better!

IMG_0503 by GaryWGraley, on Flickr

IMG_0503 by GaryWGraley, on Flickr

A shoe Brush to buff after the wax coating Link

I'll edit this first post with a listing that was in the Good Bad And Ugly feed back area

There be a lot of talented gents when it comes to leather here on the forums;

Here is a list of those that are Recommended to choose from

These guys, not in any particular order, all have a passion for leather work

so this thread can be a handy reference for future folks when they search

for someone to help with their leather needs...And please note, I only posted

those that participate in BladeForums, there are others but are not active members

so I limited the list to those in our town, so to speak

Edited to add that Dwayne Puckett, aka Leatherman, started a new thread which is also a sticky

that contains posts from leathersmiths seen hmm the old link is broken with this new software, here's a fresh link to that page https://www.bladeforums.com/threads/sheath-makers-and-such-of-blade-forums.838494/

Sandy Morrissey known on the forums as Swivelknife aka helmar45789

His Email no web site that I know of

Paul Long known on the forums as sheathmaker

his Email no web site that I know of

Mike Bartol known on the forums as MtMike

his Email

Mike has a foto time where you can view some of his work Here

Dave Abramson known on the forums as Lifter4Him

His Email

His Web page

Chuck Burrows, known on the forums as Wild Rose

His Email

His Web page

Ken Collucci's Email,

His Web page

Dwayne, known on the forum as leatherman

His Email

His Web page

Mike Tea, known on the forums as Zozzie

(removed his old email addy)

Mike's a citizen of Canada as well as a noted bicyclist

Please note, Mike Tea's sheath making has stopped for a while, he replied

on a thread on August 2, 2008, but you can search the various threads

and see some of his fine work and that may inspire you to try your hands

at his style of sheaths, very beautiful workmanship.

Vess, known on the forums as Vess...he also hails from Canada...

His Email

His Web page

Ed Alpern, known on the forums as fasteddie, Ed is an up and comer, keep an eye on this fella!

His Email

no web page yet, but soon.

***********************************************************************************

And now back to the thread where it began;

Hey folks, traveling a lot lately, but now home for a bit so figured I'd add some

of what I do, there are many ways to skin a cow, this is just one of those stories

First you start with this;

madcow by GaryWGraley, on Flickr

madcow by GaryWGraley, on Flickrwell, at least part of it I buy my leather from Wickett & Craig they are out of PA

I buy what's called Shoulder leather, very tight grain, the good stuff

For Vertical sheaths I use 7/8 oz leather, depending on the size

if it's a very small knife, I'll use the 6/7 oz

For the top sections of the horizontal sheaths, I use 6/7 oz leather

for the layer beneath the knife and the belt loop section I use

a little thicker, 7/8 oz leather

And yes, it is a little thick to form, it is stubborn stuff and always wants

to retract back to it's original flat shape, so you need to KEEP working the

leather repeatedly as it goes from wet to it's dry state, that's key to making

the leather retain it's shape.

Tools, mostly from Tandy back in the day, now my tools are quite aged

much like the user, but I hear tell that Tandy is making a come back in

leather, but see this Link to Tandy for their current offerings.

if you have a tax id number, Weaver Leather also provides nice leather as well as a host of tools.

Tools;

Knife, of course a knife, this one is a Custom by a friend, Tony Bose, I made

a special request and he honored me with this gift of a small carving knife, I don't

know of another knife maker that is as kind a man as he is, thanks again Tony!

Sucker is Sharp! Link

Bone folder, used to do the majority of my shaping around the knife

I use the SQUARE end to do my shaping, there is a rounded piece that you pull off and

it shows the square end, also if there are any maker marks on the tool, sand that down

so it's VERY smooth, don't want that scratching your leather.

The pointed end of the bone folder I use to burnish the crease that I put at the opening

of the sheaths once it's about dry, I just run that along in the groove, VERY carefully as you

can slip out of the thin groove pretty easily, and that tip will deepen and burnish the groove for you nicely.

IMG_0490 by GaryWGraley, on Flickr

IMG_0490 by GaryWGraley, on FlickrStitching Prongs, I have three that I use, a 4 prong for long stretches

3 prong for some curves and a 'custom' 2 prong for going into tight quarters

IMG_0499 by GaryWGraley, on Flickr

IMG_0499 by GaryWGraley, on FlickrMallet for said stitching prongs and embossings

IMG_0505 by GaryWGraley, on Flickr

IMG_0505 by GaryWGraley, on FlickrRuler and pencil, nuff said

IMG_0500 by GaryWGraley, on Flickr

IMG_0500 by GaryWGraley, on FlickrGroover, I use this to place a groove near the openings of the sheath, to me it

provides a more finished look to the sheath; Link

Edge beveler/cutter, this takes off a sharp corner of the leather, comes in

several sizes Link

Awl and custom awl made from a small screwdriver, used to hammer through thick

layers of leather to prepare for sewing, the regular awl I use to start the thread

holes and to enlarge the last few holes for the ending of the sewing;

Link

Awl-n-Awl sewing tool, some guys use the two needle system, I like this method for my sheaths;

IMG_0495 by GaryWGraley, on Flickr

IMG_0495 by GaryWGraley, on FlickrThread I use Link

Gunk, well, sort of, Oil dye, Gum, and Atom balm wax EDITED to say that I NO LONGER use the Atom Balm wax but now use a leather preservative that is more like a paste, works better and protects a lot better!

IMG_0503 by GaryWGraley, on Flickr

IMG_0503 by GaryWGraley, on FlickrA shoe Brush to buff after the wax coating Link

Last edited:

initial

initial cutdown

cutdown cutslits

cutslits cutout

cutout formtightly

formtightly DC

DC IMG_1972

IMG_1972 skull9

skull9 skull10

skull10 skull11

skull11 IMG_1973

IMG_1973 IMG_1974

IMG_1974 IMG_1977

IMG_1977 IMG_1978

IMG_1978 IMG_1979

IMG_1979 IMG_1980

IMG_1980 IMG_1981

IMG_1981 IMG_1982

IMG_1982 IMG_1983

IMG_1983 IMG_1985

IMG_1985 IMG_1990

IMG_1990 IMG_1988

IMG_1988 IMG_1991

IMG_1991 IMG_1989

IMG_1989 IMG_1992

IMG_1992 IMG_1993

IMG_1993 IMG_1994

IMG_1994 IMG_1995

IMG_1995 IMG_1997

IMG_1997 IMG_2001

IMG_2001 IMG_0489

IMG_0489 skull1

skull1 skull2

skull2 skull3

skull3 skull4

skull4 skull5

skull5 jollybenn

jollybenn