I think you're setting up a false argument. You acknowledge that geometry, steel alloy and heat treat are all important, but the thrust of your argument comes down to this: "But if we were to pick one factor that is the “most important” I’m not sure that heat treatment would be the one."

Trying to pick which one of those three factors is most important is like asking which leg of a three-legged stool is most important. Yes, geometry cuts, but steel alloy and heat treat determine how much geometry a blade can support.

I have a S30V blades that chip easily. I have S30V blades in the same geometry that don't chip with the same use. The difference is in the heat treat.

I bought a large custom blade in CPM 3V that dented and rolled with every strike into soft, clear-grained Doug fir. I have a large custom blade in the same steel and same geometry that isn't affected by the same use.

The difference is heat treat.

Ed Fowler, in

Knife Talk, describes complex, multi-quench heat treats that "resulted in an increase in cutting performance of 300 percent over previous 52100E blades from virgin steel... ." He said, "One of the blades was flexed back and forth a full 180 degrees 6 1/2 times before the edge cracked." How many 52100 blades can achieve that level of performance?

I have two EDCs that I use for chopping. One blade is Vanax SuperClean, a beautiful steel but not especially tough when compared to carbon steels. I have another blade in A8(mod), a super tough steel with the same geometry.

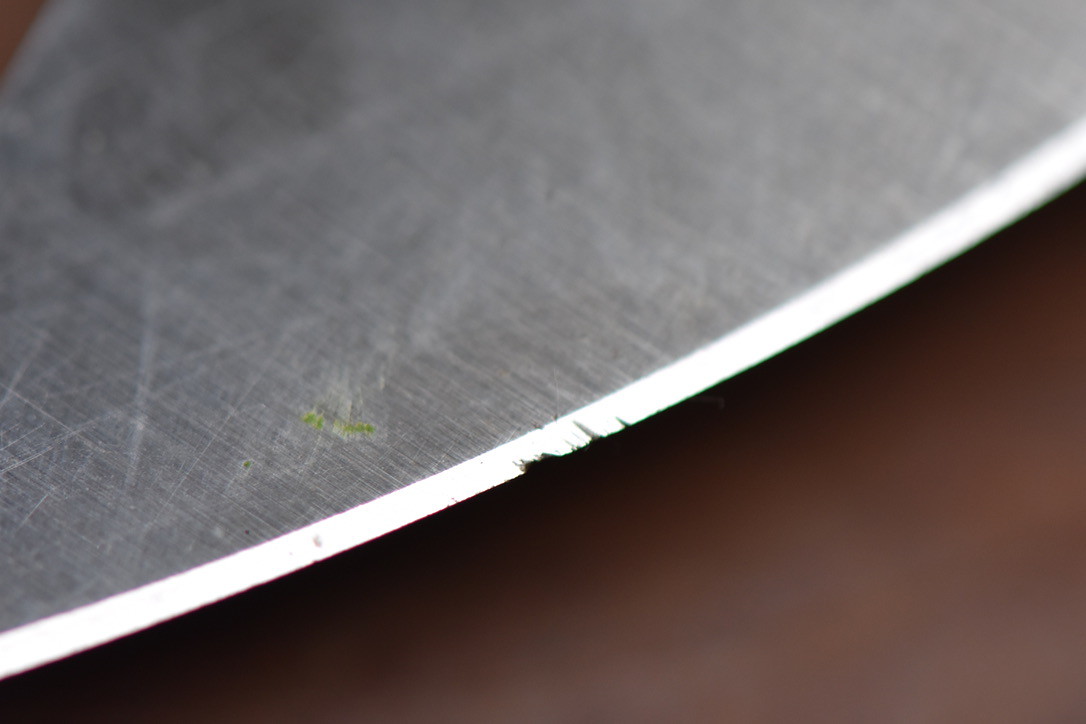

The Vanax can chop all day long without damage. The tougher A8(mod) blade failed quickly in the same use. The problem isn't the steel, but rather something that went wrong in the heat treat. Here's a shot of the A8(mod) blade after some light chopping:

Just as steel alloy and geometry will exhibit huge differences in knife performance, so can heat treat.