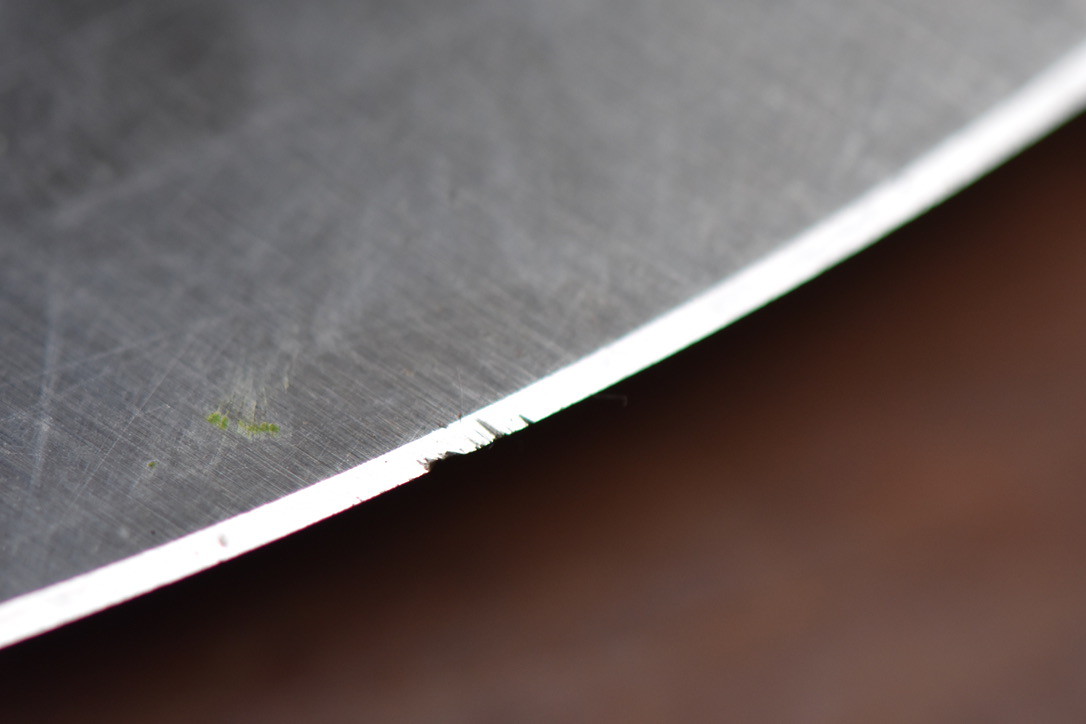

This is A8 Mod at 59/60 Hrc. 4.5 mm thick with full convex geometry.

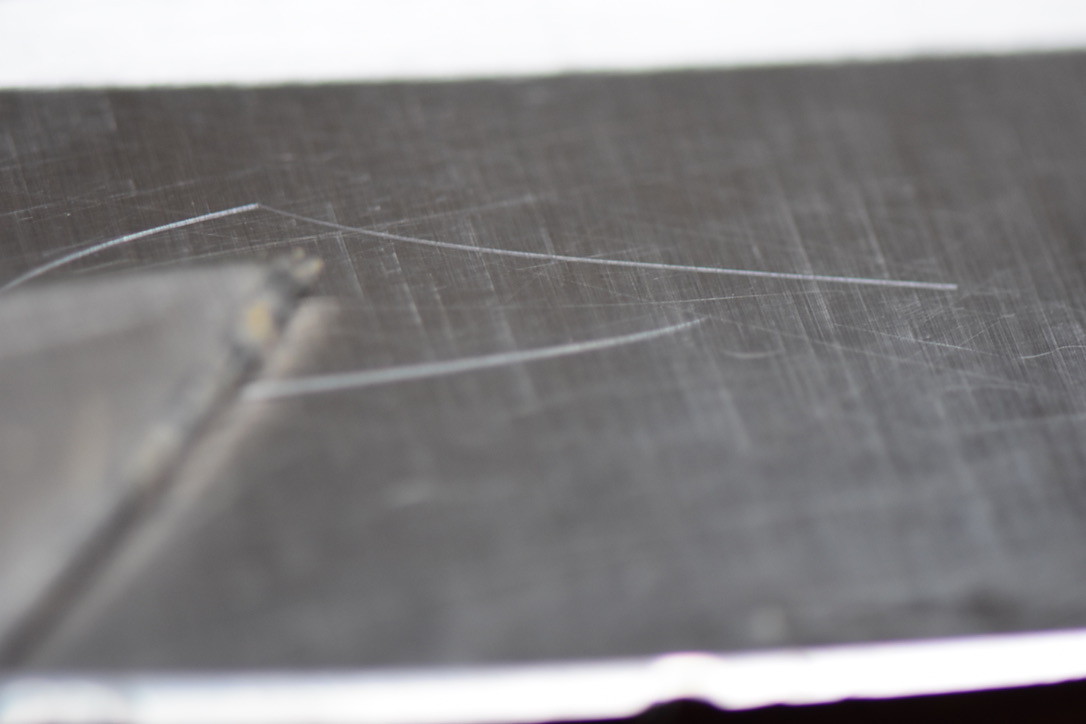

I started with hammering the front into this fresh and crooked apple tree log. Then bent the blade and hammered the rest in. Came back out dead straight, sharp and without chips or cracks. My go to steel for 6"+ blades. Has the wear resistance of A2, but significantly more toughness.

The knife:

www.bladeforums.com

www.bladeforums.com

I started with hammering the front into this fresh and crooked apple tree log. Then bent the blade and hammered the rest in. Came back out dead straight, sharp and without chips or cracks. My go to steel for 6"+ blades. Has the wear resistance of A2, but significantly more toughness.

The knife:

Lightweight 6" wood's knife A8 Mod

I made this for myself since I wanted a blade light enough to carry effortlessly but strong enough to baton wood without whining. 4.5 mm blade, full convex at 59/60 Hrc. Tapered tang for balance. Corby rivets, and two internal/hidden pinns in the front for extra strength. Canvas micarta, G10...

www.bladeforums.com

www.bladeforums.com