You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Beckerhead Knife Making and Modification Thread

- Thread starter granitestateofmind

- Start date

Tanker 1/66

Gold Member

- Joined

- May 18, 2015

- Messages

- 5,191

Tanker 1/66

Gold Member

- Joined

- May 18, 2015

- Messages

- 5,191

Thanks daizee. I have my momentsSweet mod, Tank!

- Joined

- Oct 18, 2018

- Messages

- 5,514

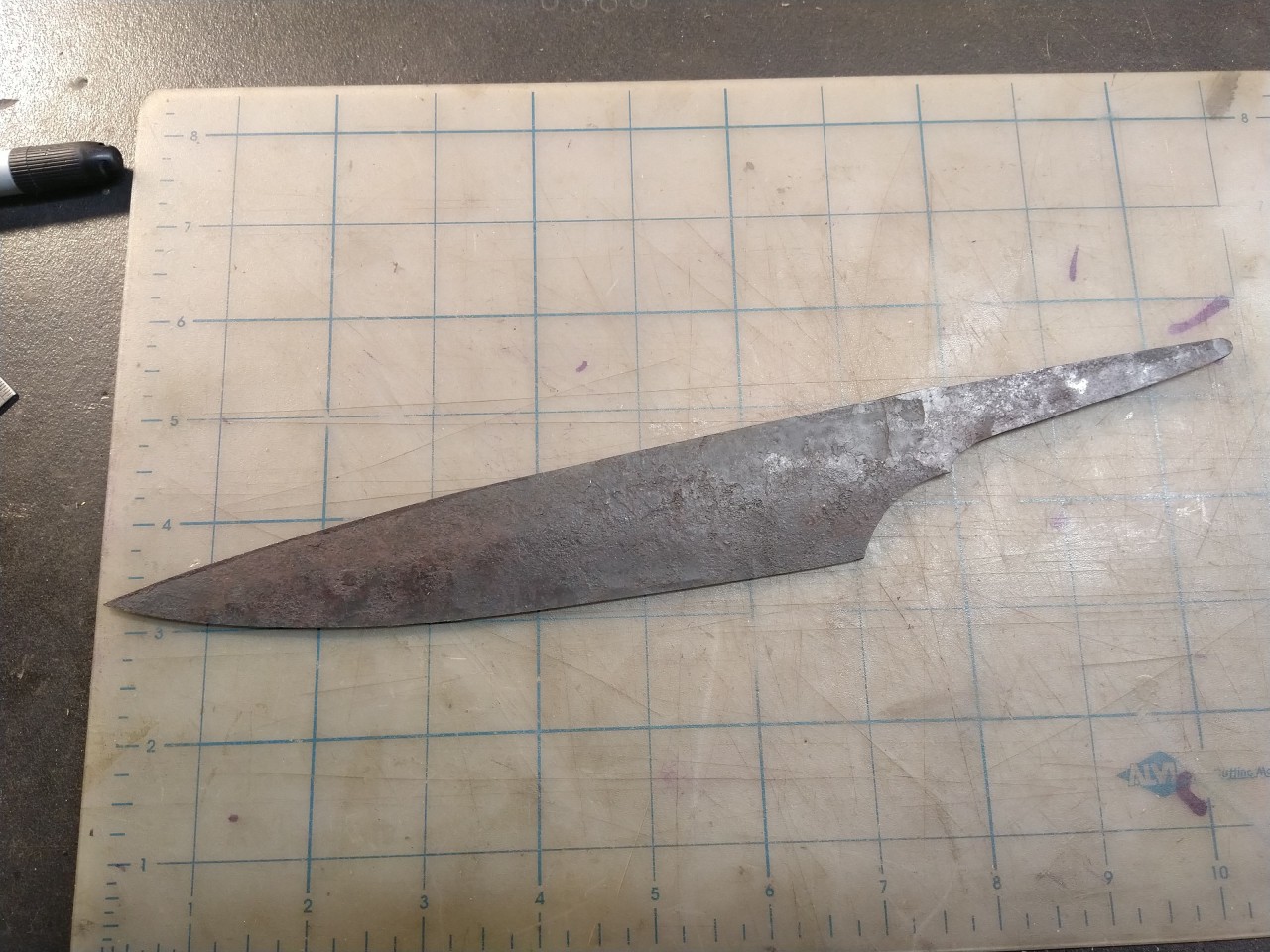

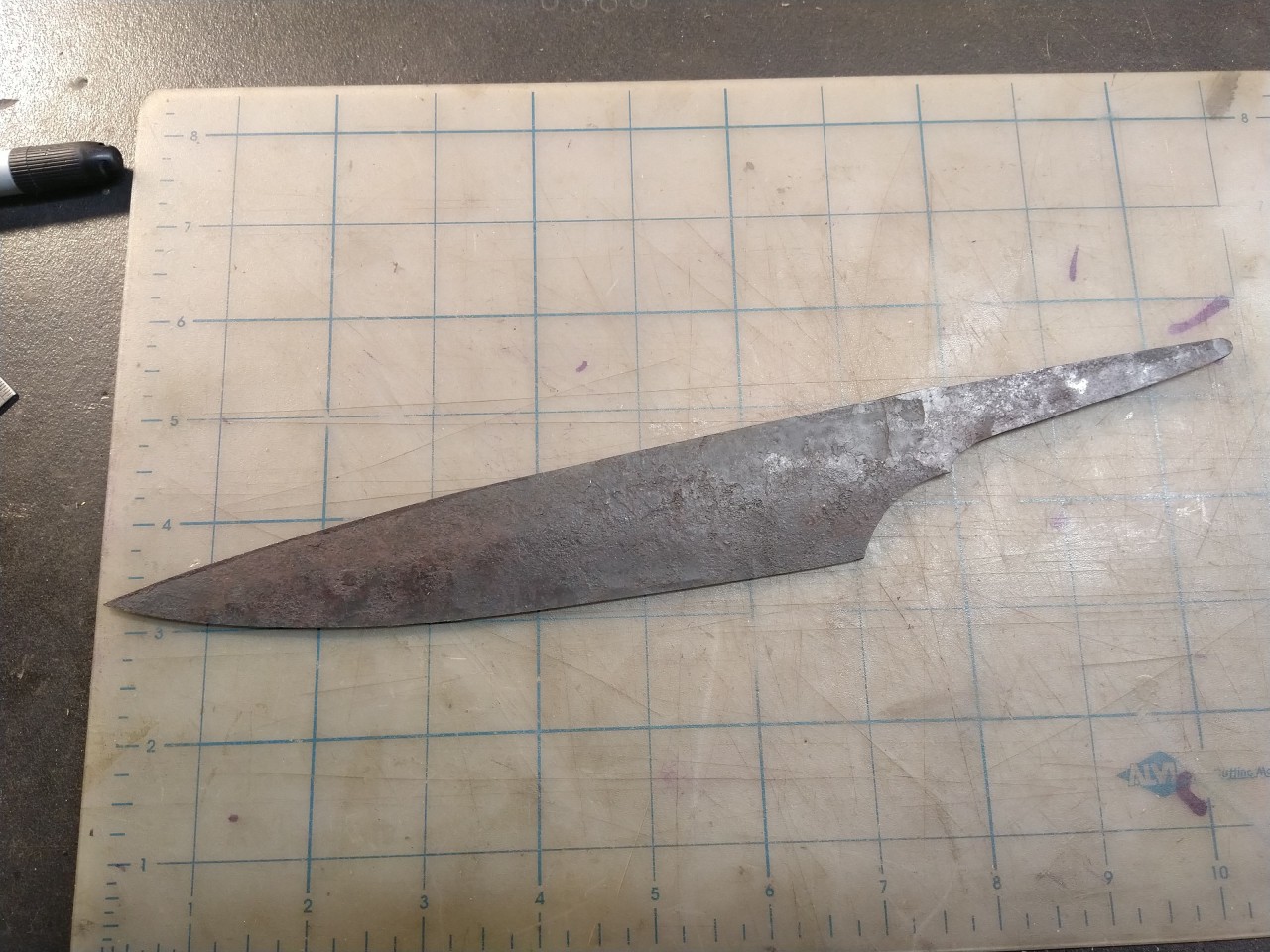

Anybody remember my first one?

This is just roughed/sawed out.

Tons of work still.

I might not get much done till next week, but I wanna send out for hea-treating soon with some more stuff.

Not sure I agree with it.....but I'm flipping my handle configuration around, opposite of my first one. Seems like that was a concern of some.

I'll get to try out both versions for a good comparison.

I'm also toying around with the idea of holes instead of slots?

I think it might be stronger without the straining of the metal in the slots, idk?

Easier to make too, unless I get a bunch lasered.....

I'd want to talk upstairs before I sold any.

I wouldn't even know how to do that, Smoke signals? Lol.

This one is Thicker, and AEB-L. Should be a tank. Great to be left outside in the backyard by the grill or fire pit.

This is just roughed/sawed out.

Tons of work still.

I might not get much done till next week, but I wanna send out for hea-treating soon with some more stuff.

Not sure I agree with it.....but I'm flipping my handle configuration around, opposite of my first one. Seems like that was a concern of some.

I'll get to try out both versions for a good comparison.

I'm also toying around with the idea of holes instead of slots?

I think it might be stronger without the straining of the metal in the slots, idk?

Easier to make too, unless I get a bunch lasered.....

I'd want to talk upstairs before I sold any.

I wouldn't even know how to do that, Smoke signals? Lol.

This one is Thicker, and AEB-L. Should be a tank. Great to be left outside in the backyard by the grill or fire pit.

Last edited:

daizee

Knifemaker / Craftsman / Service Provider

- Joined

- Dec 30, 2009

- Messages

- 10,905

Anybody remember my first one?

This is just roughed/sawed out.

Tons of work still.

I might not get much done till next week, but I wanna send out for hea-treating soon with some more stuff.

Not sure I agree with it.....but I'm flipping my handle configuration around, opposite of my first one. Seems like that was a concern of some.

I'll get to try out both versions for a good comparison.

I'm also toying around with the idea of holes instead of slots?

I think it might be stronger without the straining of the metal in the slots, idk?

Easier to make too, unless I get a bunch lasered.....

I'd want to talk upstairs before I sold any.

This one is Thicker, and AEB-L. Should be a tank. Great to be left outside in the backyard by the grill or fire pit.

I wouldn't even know how to do that, Smoke signals? Lol.

Whee!!

How thick is the AEB-L?

Slots? In the handle? Those are for balance, presumably. With all that blade I think you'd want as much weight in the handle as possible. But in either case, drilling holes is easier unless you have a milling machine.

- Joined

- Oct 18, 2018

- Messages

- 5,514

I have access to a machine shop......Whee!!

How thick is the AEB-L?

Slots? In the handle? Those are for balance, presumably. With all that blade I think you'd want as much weight in the handle as possible. But in either case, drilling holes is easier unless you have a milling machine.

I meant holes so the friction from the flipped meat is less....lol

Not in the handle.

Some spatulas are with nothing, some have slots, some holes......

My first one was slotted.

I'm over 2.5 pounds as now..... It's too heavy.

So adding holes and slots will lighten it and Ballance it better.

I just don't want the heat treat getting it wavey

I don't have my first spatula in front of me, it's at work..... It's almost perfect.

This one is thicker. Idk if I went overboard......

I guess that's why we make prototypes.

I don't have my micrometer, but it's close to .150"

daizee

Knifemaker / Craftsman / Service Provider

- Joined

- Dec 30, 2009

- Messages

- 10,905

Oh, a SPATULA!!

Yeah, gonna have to put that bad boy on a diet and decide how hard you want it.

AEB-L doesn't have super high heat tolerance, but you're not making a knife blade, so I think you're going to end up with a SUPER tough tool at sub-knife-hardness. Sounds like a good plan to me!

Yeah, gonna have to put that bad boy on a diet and decide how hard you want it.

AEB-L doesn't have super high heat tolerance, but you're not making a knife blade, so I think you're going to end up with a SUPER tough tool at sub-knife-hardness. Sounds like a good plan to me!

- Joined

- Oct 18, 2018

- Messages

- 5,514

Sub knife?Oh, a SPATULA!!

Yeah, gonna have to put that bad boy on a diet and decide how hard you want it.

AEB-L doesn't have super high heat tolerance, but you're not making a knife blade, so I think you're going to end up with a SUPER tough tool at sub-knife-hardness. Sounds like a good plan to me!

Honesty, I'm thinking 58-60R

I'm going to Beat the snot out of it......

In my ignorant opinion...... 3 seconds to flip a burger, or move some coals should be ok?

Or, maybe I'll get some soft spots? :0. Even so, at this thickness ( I'm giving it a chisel grind, like I did the first) it Should be fairly Stout

We shall see......

- Joined

- Oct 18, 2018

- Messages

- 5,514

This was my first.... I Love it!Oh, a SPATULA!!

Yeah, gonna have to put that bad boy on a diet and decide how hard you want it.

AEB-L doesn't have super high heat tolerance, but you're not making a knife blade, so I think you're going to end up with a SUPER tough tool at sub-knife-hardness. Sounds like a good plan to me!

The next one I started is my second prototype.

Spatula, Spatula! wherefore art thou Spatula?

I've been dreaming of a good spatula for over 5 years. I feel that I've been needing a real good one for a long time now, without any end in sight..... So.... I decided to make one.... I'm probably 75% finished. I still need to clean up the grind lines, remove some milling marks, touch up the...

www.bladeforums.com

www.bladeforums.com

- Joined

- Oct 18, 2018

- Messages

- 5,514

That's a good idea adding weight.

I made some brass liners for my 21, that helps alot.

daizee

Knifemaker / Craftsman / Service Provider

- Joined

- Dec 30, 2009

- Messages

- 10,905

375F temper puts AEB-L at ~61Rc.

Just speculating, but I'd expect your "edge" to get up to 500F on the surface, but only the VERY surface/edge. So it won't hold a KNIFE edge very well (where it gets hot), but should be fine for everything else. If you won't need an actual knife edge, I think anything from 45-58Rc would be great for a brutal spatula. More than 58 in AEB-L doesn't buy you anything except brittleness (in this application), IMO. Though AEB-L is ridiculously tough as hardened steels go anyway. There may be a toughness peak in AEB-L in the 60-61 range. Hotter/softer may be less tough (local minimum), but I'd have to go look at Larrin's charts.

Coals will be VERY hot, not the air temp or grill-grate temp. But with that mass it won't absorb heat TOO fast.

Another thing to note: The higher temps the steel reaches in temper or in use, the less stain-resistant it will be. So if you'll care about that real hard, keep the edge that gets hottest dry.

In any case, it's gonna be awesome.

Just speculating, but I'd expect your "edge" to get up to 500F on the surface, but only the VERY surface/edge. So it won't hold a KNIFE edge very well (where it gets hot), but should be fine for everything else. If you won't need an actual knife edge, I think anything from 45-58Rc would be great for a brutal spatula. More than 58 in AEB-L doesn't buy you anything except brittleness (in this application), IMO. Though AEB-L is ridiculously tough as hardened steels go anyway. There may be a toughness peak in AEB-L in the 60-61 range. Hotter/softer may be less tough (local minimum), but I'd have to go look at Larrin's charts.

Coals will be VERY hot, not the air temp or grill-grate temp. But with that mass it won't absorb heat TOO fast.

Another thing to note: The higher temps the steel reaches in temper or in use, the less stain-resistant it will be. So if you'll care about that real hard, keep the edge that gets hottest dry.

In any case, it's gonna be awesome.

- Joined

- Oct 18, 2018

- Messages

- 5,514

I agree, I'll need to take a fair amount out.....150 is garden hatchet/weeding tool territory.

you'll need 1/8 or 3/16" slots 1/8" apart to drop the weight significantly

I still haven't done the math yet on its missing area, but

I've got five rows of 3/8" holes. With a slot in the middle for opening gas valves, and grill vents, whatever .....with a pot lifter notch on the end of the big curve. The big curve acts as a supportive hand hold.

All of these features were on my first, and they worked really well.

The main difference is the blade thickness, and I'm trying holes instead of slots?

- Joined

- Oct 18, 2018

- Messages

- 5,514

Thank..... All that sounds good.375F temper puts AEB-L at ~61Rc.

Just speculating, but I'd expect your "edge" to get up to 500F on the surface, but only the VERY surface/edge. So it won't hold a KNIFE edge very well (where it gets hot), but should be fine for everything else. If you won't need an actual knife edge, I think anything from 45-58Rc would be great for a brutal spatula. More than 58 in AEB-L doesn't buy you anything except brittleness (in this application), IMO. Though AEB-L is ridiculously tough as hardened steels go anyway. There may be a toughness peak in AEB-L in the 60-61 range. Hotter/softer may be less tough (local minimum), but I'd have to go look at Larrin's charts.

Coals will be VERY hot, not the air temp or grill-grate temp. But with that mass it won't absorb heat TOO fast.

Another thing to note: The higher temps the steel reaches in temper or in use, the less stain-resistant it will be. So if you'll care about that real hard, keep the edge that gets hottest dry.

In any case, it's gonna be awesome.

I'll make a mental note pushing coals Opposite the edge.

I kept my first one pretty dull. Definitely not a knife edge.

I didn't measure, but around .015- .020" at the edge.

Scraping gunk off my grates was my "honing technique".

even still being dull, it chopped branches, battoned, and cleaves chickens.

The weight of the blade just zings through material.....haha

daizee

Knifemaker / Craftsman / Service Provider

- Joined

- Dec 30, 2009

- Messages

- 10,905

The slots are really cool. I don't know why.

Maybe because I don't have a way of doing that in my shop.

What's your thinking on the handle orientation? It looks upside-down at first glance, but clearly you made that decision on purpose.

Maybe because I don't have a way of doing that in my shop.

What's your thinking on the handle orientation? It looks upside-down at first glance, but clearly you made that decision on purpose.

- Joined

- Oct 18, 2018

- Messages

- 5,514

Each prototype has a different handle orientation.The slots are really cool. I don't know why.

Maybe because I don't have a way of doing that in my shop.

What's your thinking on the handle orientation? It looks upside-down at first glance, but clearly you made that decision on purpose.

My first one I did it "upside down" on purpose. It seemed supportive to me.

I must have weird shaped hands? I struggle with handle comfort.

The second one I'm making more conventional.

Idk if it will feel as comfortable to Me? But it will be a nice comparison, and I'll definitely know which way going forward....

daizee

Knifemaker / Craftsman / Service Provider

- Joined

- Dec 30, 2009

- Messages

- 10,905

The first of these pix happened a week or two ago, but today I ground one of the 4.5" pieces clean and threw it in the forge. I also decided that the Kabar spork is sub-optimal as both a spoon and a fork, so I made it more fork-like (after flinging salad on myself with it at work last week):