Not sure if I am in the correct place, so please redirect me if appropriate.

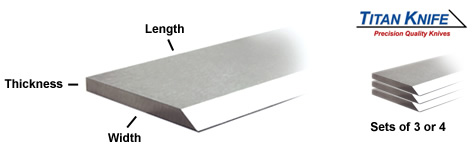

I am making a couple wooden cabbage slicers and I need to source (or create) some blades. I have the woodworking portion covered just fine, but I am struggling with the steel blades.

Option #1: find someone locally (central Iowa) to make the blades for me

Option #2: make them myself.

If I go with option #2, I would appreciate recommendations on a couple things.

1) grade of steel

2) methods to grind an edge (I would love to do some reading - I am sure it has been covered plenty times before - I just need someone to point me in the correct direction)

I understand that I can probably find an old cheap one at a garage sale or auction, but I love woodworking, and I hope this will turn into a nice project for me (dovetailed joinery, etc).

I appreciate any and all direction.

Thanks,

brausch

I am making a couple wooden cabbage slicers and I need to source (or create) some blades. I have the woodworking portion covered just fine, but I am struggling with the steel blades.

Option #1: find someone locally (central Iowa) to make the blades for me

Option #2: make them myself.

If I go with option #2, I would appreciate recommendations on a couple things.

1) grade of steel

2) methods to grind an edge (I would love to do some reading - I am sure it has been covered plenty times before - I just need someone to point me in the correct direction)

I understand that I can probably find an old cheap one at a garage sale or auction, but I love woodworking, and I hope this will turn into a nice project for me (dovetailed joinery, etc).

I appreciate any and all direction.

Thanks,

brausch