Willie71

Warren J. Krywko

- Joined

- Feb 23, 2013

- Messages

- 12,214

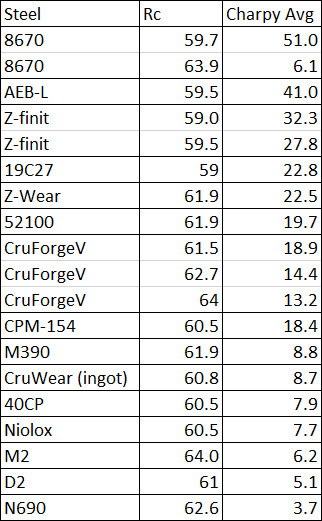

Can’t remember, Larrin, did Warren went down to 57hrc with 8670, where it has even more toughness?

How amused I’ll be if this “simple” steel reveals to be tougher at 60hrc than 3v at that same hardness, no matter the way it is tempered (high or low temper)!

I just did the two samples. I thought I did more, but the more complete sets of samples evolved later in the process. The charts said that sample should have been Rc56, so I will do more tempered even higher, as well as lower to see where the toughness takes a nose dive.