- Joined

- Apr 17, 2015

- Messages

- 91

So...planning out test conditions for some steel. Input would be welcome, please speak up if you have a particular condition you would like to see tested or have any experience that might help.

CPM S35VN: Data sheet shows 1900f to 2000f aus temp, both low temper and high. Any reason to include high tempers? Prequench?

X50CrMoV15: This one will be weird, as manufacturers are all over the board on their HT (as far as I can tell). I will do some cryo, some not, some low temper, some high. Seems most run it either at 55-56 HRC, or at full hardness of around 58 with cryo, so I will include those at a minimum.

A2: Should be pretty standard, possibly test prequench?

A8M: This is chipper knife steel. Tough stuff! I have access to a bunch of used chipper knives but they will require quite some effort to anneal and saw. Any interest in including it, or is it not worth the pain?

Michael

Yeah I wouldn't bother with upper temper for S35VN.

I will try to figure out heat treatment for 1.4116 tomorrow.

Would you like some L6 samples as well?Why not go for Rc58, Rc60, and Rc62?

I’ll add this to my “to be completed” list.

Would you like some L6 samples as well?

E40B4FF9-72F9-49BE-9BAD-6DAF554F37E3 by Wjkrywko, on Flickr

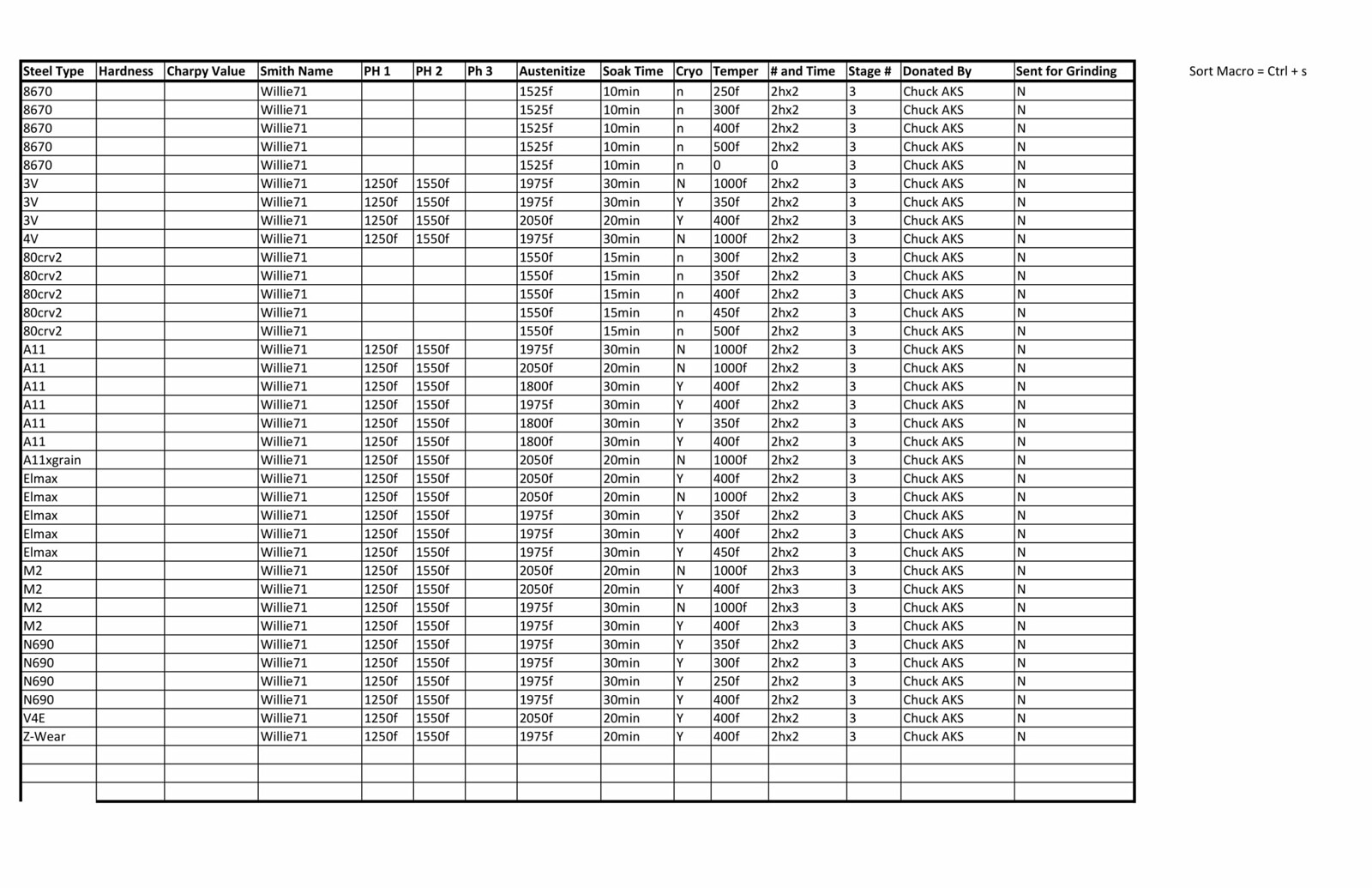

E40B4FF9-72F9-49BE-9BAD-6DAF554F37E3 by Wjkrywko, on FlickrBusy man!Ok, after several hours of squinting st samples to make sure I could read my etching through the decarb and scale, here is what is ready today. I’ll do a list of what is promised tomorrow. I’d love to get it done tonight, but my eyes are crossed. Getting old sucks.

E40B4FF9-72F9-49BE-9BAD-6DAF554F37E3 by Wjkrywko, on Flickr

I have Republic and champaloy with MolybdenumI did a bunch with Aldo's stock. If you have stock with Moly, that would be great.

I have Republic and champaloy with Molybdenum

Hi All,

I've realized I can't effectively contribute labor to this effort.

But I CAN contribute steel/money. Is there interest in adding Nitro-V to the mix, with a couple variations in Aus. temps, plus sub-zero and several tempers?

Is there another type of steel already planned, but for which stock is lacking?

I would be delighted to order an appropriate piece or two of stock from NJSB to be delivered to the appropriate person in the chain.

Please, Larrin, Warren, JT, etc. PM if interested.

-E

Hi All,

I've realized I can't effectively contribute labor to this effort.

But I CAN contribute steel/money. Is there interest in adding Nitro-V to the mix, with a couple variations in Aus. temps, plus sub-zero and several tempers?

Is there another type of steel already planned, but for which stock is lacking?

I would be delighted to order an appropriate piece or two of stock from NJSB to be delivered to the appropriate person in the chain.

Please, Larrin, Warren, JT, etc. PM if interested.

-E

I meant to get the “in the works” list completed yesterday. I’ll do my best to get it up tonight.

Hi All,

I've realized I can't effectively contribute labor to this effort.

But I CAN contribute steel/money. Is there interest in adding Nitro-V to the mix, with a couple variations in Aus. temps, plus sub-zero and several tempers?

Is there another type of steel already planned, but for which stock is lacking?

I would be delighted to order an appropriate piece or two of stock from NJSB to be delivered to the appropriate person in the chain.

Please, Larrin, Warren, JT, etc. PM if interested.

-E