Ian Weller

Gold Member

- Joined

- Aug 16, 2017

- Messages

- 174

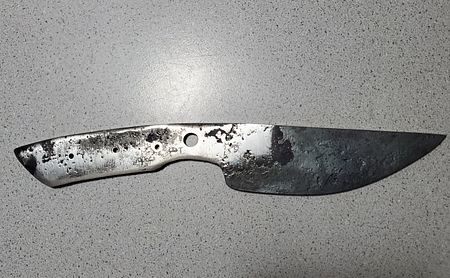

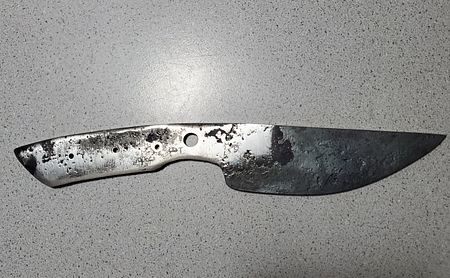

Hello everyone, I am new to posting on bladeforums so I apologize if I am in the wrong place posting this. I recently forged a "hunting knife" from a piece of leaf spring, I am assuming its 5160 but who knows? Besides a three broken drill bits this has been a fun project. I have yet to heat treat this knife, and haven't really done much grinding yet, but my biggest issue is this atrocious finger well. Somehow I got carried away with the dremel and made it much much wider than I wanted. I am wondering what I can do to fix it at this point? Or if I should go with it, quench and finish the handle, etc.

many times i have had to make a mistake look like i "meant it"

many times i have had to make a mistake look like i "meant it"