- Joined

- Jan 29, 2014

- Messages

- 1,638

Projects are just kinda piling up so I think this'll just be an ongoing thread of all the stuff that occupies my free time.

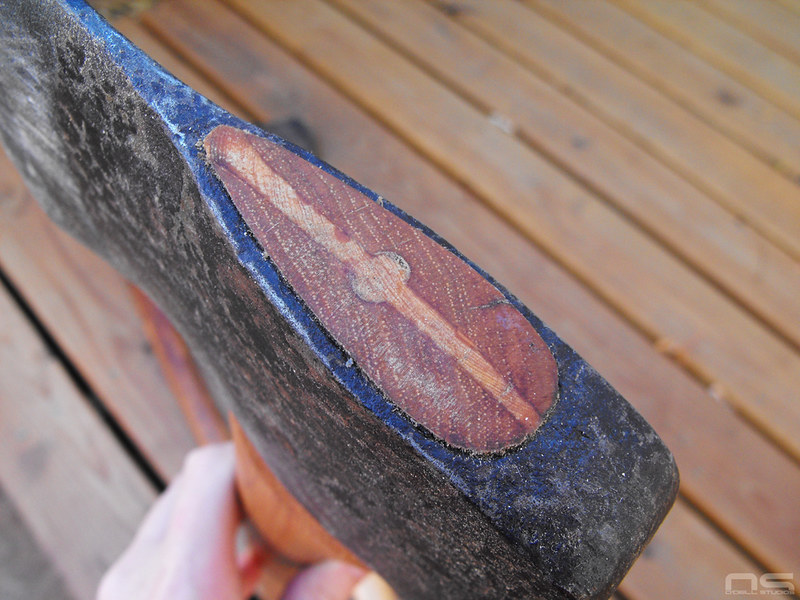

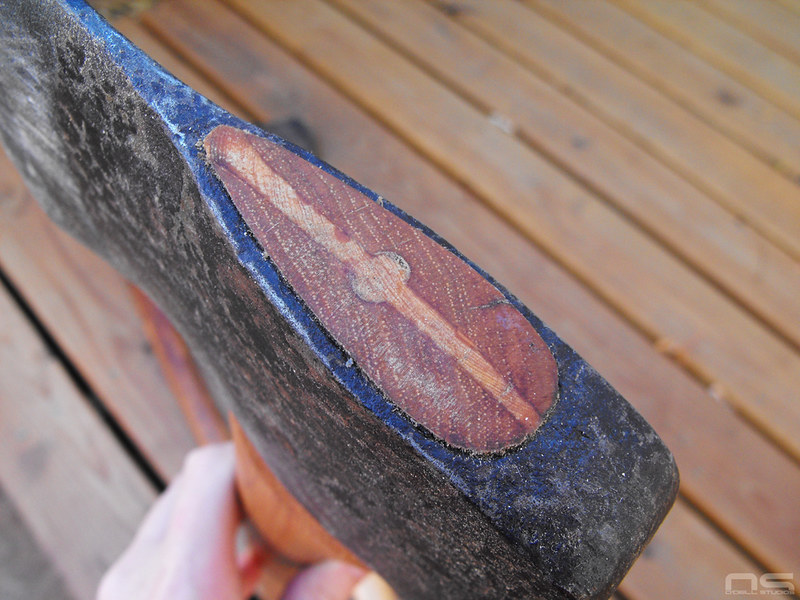

This pile is from a friend of mine - I never know what he might show up with and for this group I talked him out of spending any time on the Keen Kutter. It's unfortunate but the bit is worn through on the corners to the point that the wrought is showing through. The other axe on the other hand is only marked on the underside of the poll with a 2 in a circle. It sorta shows in one of the pics. It has a great shape and bit/cheek profile IMO and comes in at exactly 3-1/2 pounds. It's now wearing a House Handle that got a enormous amount of thinning and shaping - appears to be full heart wood. The handles on both these axes may not have been original but they do seem to be old and are very nice. I don't like 36 inch handles but he wanted new sticks and I am glad to have these as reference to how handles should look. I actually think they are still in usable condition so I cleaned one of them up to have a look.

rehang_projects by city_ofthe_south, on Flickr

rehang_projects by city_ofthe_south, on Flickr

noname_wedges by city_ofthe_south, on Flickr

noname_wedges by city_ofthe_south, on Flickr

noname_finished by city_ofthe_south, on Flickr

noname_finished by city_ofthe_south, on Flickr

Scored the double bit at a local antique mall - for the first time EVER I found something good! There is nothing around here. I believe all the axes are still sitting around in barns being used in Kansas to be honest. It's a 3lb Tru-Test ... not really sure if that means it's good but man it appears to be in nice shape, save for the goofy gigantic HH handle that was put on it. I already ripped that off.

noname_handlefit by city_ofthe_south, on Flickr

noname_handlefit by city_ofthe_south, on Flickr

noname_sidebyside by city_ofthe_south, on Flickr

noname_sidebyside by city_ofthe_south, on Flickr

noname_wedge by city_ofthe_south, on Flickr

noname_wedge by city_ofthe_south, on Flickr

Anyway, the hammers are all de-handled and I've been asked to fit them with handles of similar length to what was on them - obviously some custom jobs in there.

This pile is from a friend of mine - I never know what he might show up with and for this group I talked him out of spending any time on the Keen Kutter. It's unfortunate but the bit is worn through on the corners to the point that the wrought is showing through. The other axe on the other hand is only marked on the underside of the poll with a 2 in a circle. It sorta shows in one of the pics. It has a great shape and bit/cheek profile IMO and comes in at exactly 3-1/2 pounds. It's now wearing a House Handle that got a enormous amount of thinning and shaping - appears to be full heart wood. The handles on both these axes may not have been original but they do seem to be old and are very nice. I don't like 36 inch handles but he wanted new sticks and I am glad to have these as reference to how handles should look. I actually think they are still in usable condition so I cleaned one of them up to have a look.

rehang_projects by city_ofthe_south, on Flickr

rehang_projects by city_ofthe_south, on Flickr noname_wedges by city_ofthe_south, on Flickr

noname_wedges by city_ofthe_south, on Flickr noname_finished by city_ofthe_south, on Flickr

noname_finished by city_ofthe_south, on FlickrScored the double bit at a local antique mall - for the first time EVER I found something good! There is nothing around here. I believe all the axes are still sitting around in barns being used in Kansas to be honest. It's a 3lb Tru-Test ... not really sure if that means it's good but man it appears to be in nice shape, save for the goofy gigantic HH handle that was put on it. I already ripped that off.

noname_handlefit by city_ofthe_south, on Flickr

noname_handlefit by city_ofthe_south, on Flickr noname_sidebyside by city_ofthe_south, on Flickr

noname_sidebyside by city_ofthe_south, on Flickr noname_wedge by city_ofthe_south, on Flickr

noname_wedge by city_ofthe_south, on FlickrAnyway, the hammers are all de-handled and I've been asked to fit them with handles of similar length to what was on them - obviously some custom jobs in there.

Last edited: