- Joined

- Dec 17, 2018

- Messages

- 1,192

Now that’s an athletic stance!

Old retired guys get pretty serious when it comes to "bragging rights"! (and the young guys too...)Now that’s an athletic stance!

I Wonder if Swel-Lock would work on the handles?

I Wonder if Swel-Lock would work on the handles?

4. Atkins No.3 Circular Saw Set (1948)

Well hey this is topical. I just got a NOS #3 today!

No instructions came in this box either.

hey can someone post the full page of this?

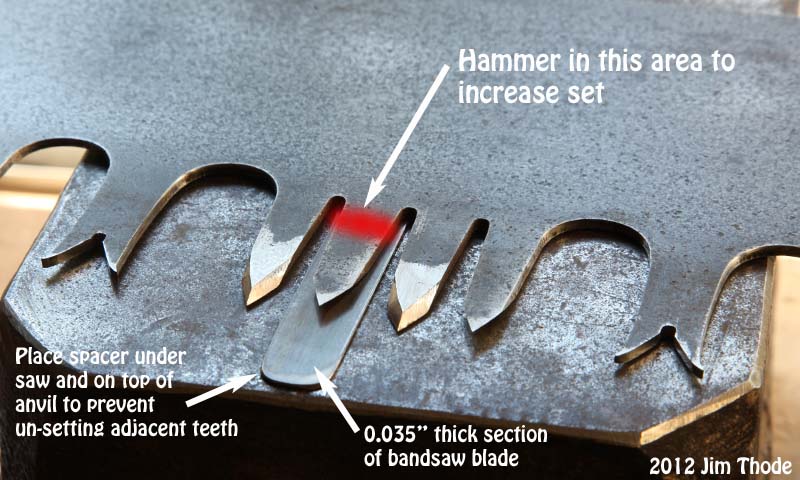

Brian Rust sent me one a few months ago and i havent had much success with it, tips on how to care for one would be great as well.

here's a pic.

I always finish my final point up after setting. Doing so allows me to back hone an exact set for every tooth.Any insight as to why Atkins suggests filing after setting? Tips on harder steel more apt to chip?

Any insight as to why Atkins suggests filing after setting? Tips on harder steel more apt to chip?

I “rehung” a lubricant bottle today but I couldn’t find where @Yankee Josh posted his last project bottle so I figured it probably belongs here anyway.......

I’d rather preserve it than ruin it but I suspect you know that.One more pic, in use, hooked to the tree you're sawing.

I “rehung” a lubricant bottle today but I couldn’t find where @Yankee Josh posted his last project bottle so I figured it probably belongs here anyway.

Interesting, that old one I have there also has a hole drilled through the stopper. Of course, no plug remaining.Nice! I've never seen one with a hole drilled through the stopper with a plug. All I've seen just have a little slot cut in the side of the stopper with no way to plug it.