- Joined

- Oct 19, 2005

- Messages

- 19,687

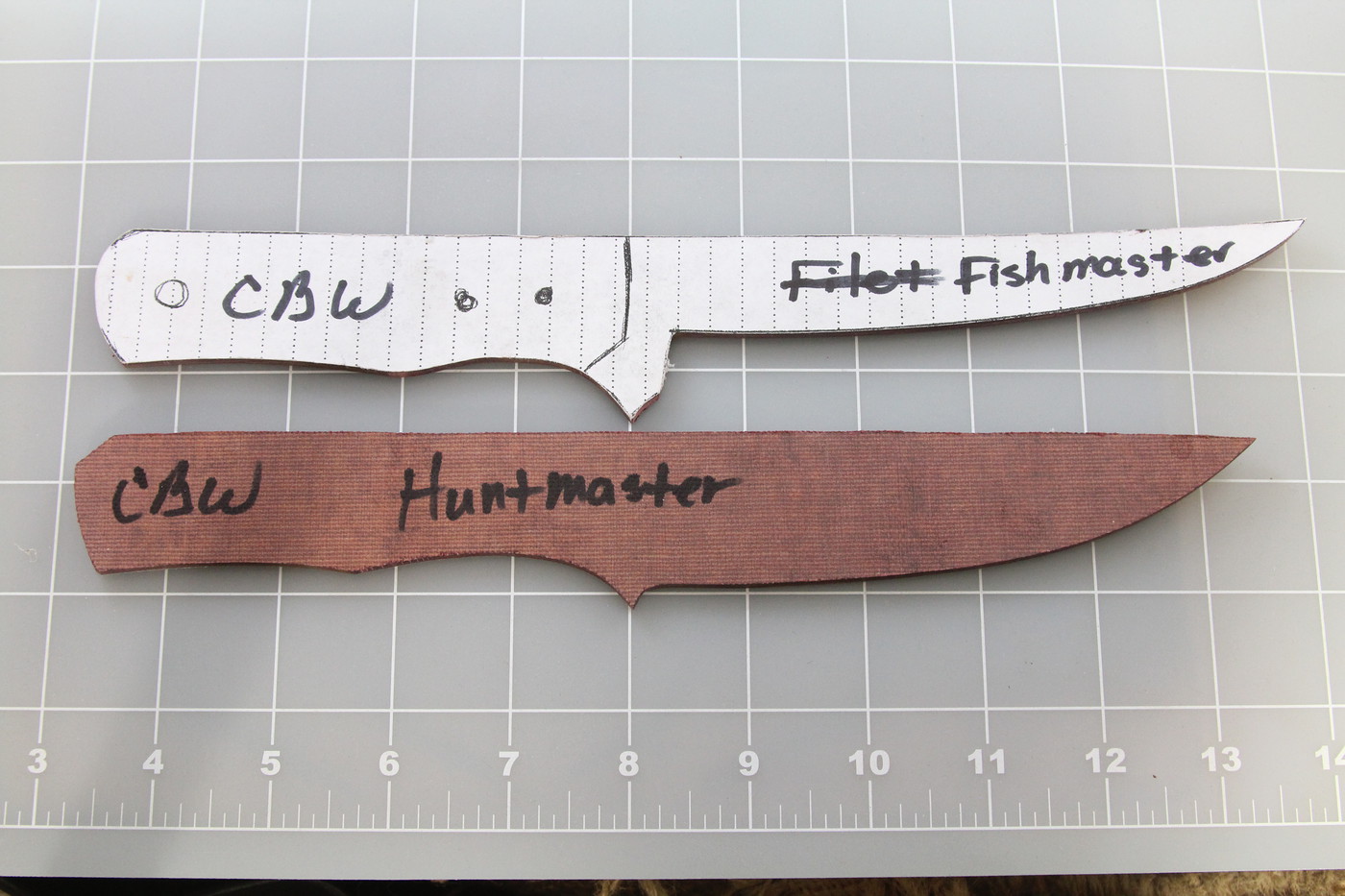

I have designed a line of knives to be made under the name Cumming Bladeworks USA. These are not Fiddleback knives at all. I will not be making the knives, but they will be made here by the apprentices on staff. We are working on branding and marks right now. These knives will not be recognizable as Fiddleback Forge knives. So far there are 8 designs ranging from an Altoids tin sized knife up to a big hunting knife and a filet knife. We won't be selling them here at the forum. They will be sold by dealers. We will be posting pics on Instagram and under Cumming Bladeworks USA.

here

here