IMHO odd shaped holes require a more advanced approach than those described above, not to denigrate using a needle file to achieve that hole cheap. Needle files can achieve the desired result albeit with blistered hands a likelihood to say nothing of serious cussing.

You need an EDM or a Waterjet

Electrical discharge machining

From Wikipedia, the free encyclopedia

Electrical discharge machining

Electrical discharge machining (

EDM), also known as

spark machining,

spark eroding,

burning,

die sinking,

wire burning or

wire erosion, is a manufacturing process whereby a desired shape is obtained by using electrical discharges (sparks).

[1] Material is removed from the work piece by a series of rapidly recurring current discharges between two

electrodes, separated by a

dielectric liquid and subject to an electric

voltage. One of the electrodes is called the tool-electrode, or simply the "tool" or "electrode," while the other is called the workpiece-electrode, or "work piece." The process depends upon the tool and work piece not making actual contact.

As an alternative but equally (I believe) accurate you could use a waterjet.

Water jet cutter

From Wikipedia, the free encyclopedia

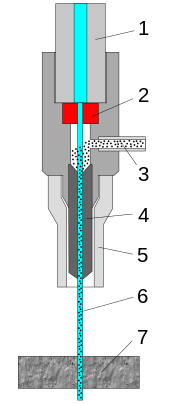

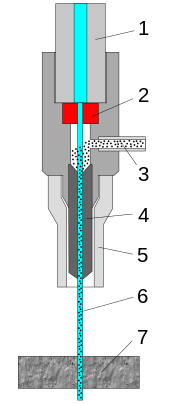

A diagram of a water jet cutter. #1: high-pressure water inlet. #2: jewel (ruby or diamond). #3: abrasive (garnet). #4: mixing tube. #5: guard. #6: cutting water jet. #7: cut material

A

water jet cutter, also known as a

water jet or

waterjet, is an industrial tool capable of cutting a wide variety of materials using a very high-pressure jet of

water, or a mixture of water and an

abrasive substance. The term

abrasive jet refers specifically to the use of a mixture of water and abrasive to cut hard materials such as metal or

granite, while the terms

pure waterjet and

water-only cutting refer to waterjet cutting without the use of added abrasives, often used for softer materials such as wood or rubber.

[1]

Waterjet cutting is often used during fabrication of machine parts. It is the preferred method when the materials being cut are sensitive to the high temperatures generated by other methods. Waterjet cutting is used in various industries, including

mining and

aerospace, for cutting, shaping, and

reaming.

Just my 2¢ of course.................. or perhaps my $20,000 (because, as my wife often remarks, I have too much money).

Corey "synthesist" Gimbel

1980-01-01 00.02.03

1980-01-01 00.02.03 440C Mop integral

440C Mop integral