- Joined

- Feb 1, 2012

- Messages

- 13,727

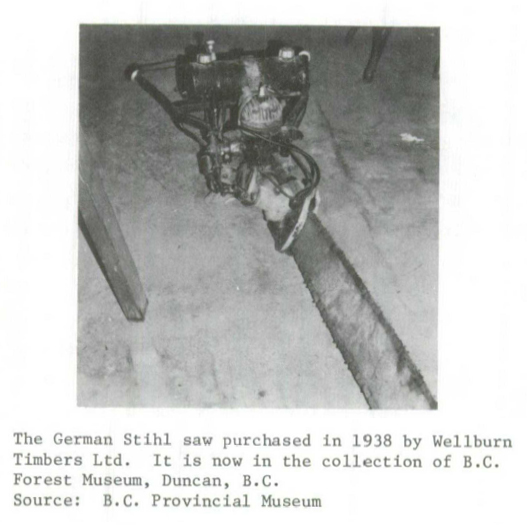

Cool stuff, definitely a very specific tool! OP needs one of those early chainsaws...

My dad had one similar to that. It was brutally heavy and he hated it worse than anything but a handsaw.

Imagine being able to saw trees down with relative ease and then having to resort back to handsaws in order to buck them into logs.

Gas powered buck saws (drag saws) had already been around for a long time.

https://www.youtube.com/watch?v=qfmzBy7p-ao

https://www.youtube.com/watch?v=j0R7Mtq2-p0

http://www.mendorailhistory.org/1_logging/drag_saws.htm

I've seen a few drag saws rusting away in barns around here.