- Joined

- Jun 25, 2017

- Messages

- 908

X

Last edited:

The advantage is a clear sight and good body position in relation to the work on the billet standing on its chopping block

No, not on the poll. The one on the side of the blade? Within the oval. I've seen that logo a couple of times before. That was a cleaned logo from France with to swords (sort of scimitars?) I could probably figure the maker out, as wel as an aproximate period. I believe they where somewhere from around the 1960-1980.

such a good, unbiased way to get acquainted with a good axe. I find myself in many situations also "automatically" reaching for the one axe over the other, consistently and over time.seem to instinctively reach for the Stubai even though there's no danger of barking a knuckle in whatever carving I'm doing at the stump. The Stubai just somehow presents itself to the work easier. I hadn't really thought about it till now.

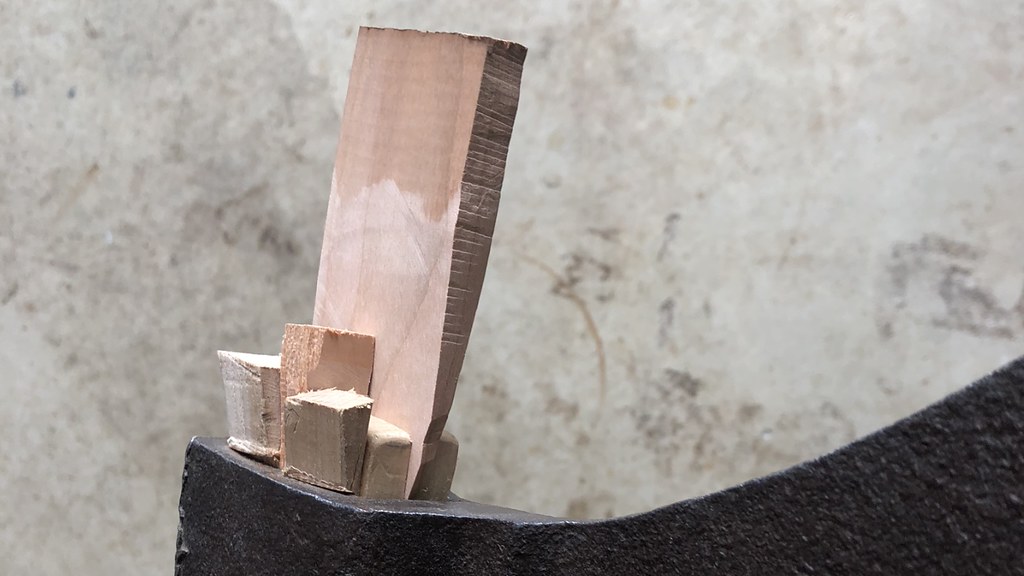

It looks like much of the packing is on the outside of the off-set. Was this to get at the angle you were after? It's not a bad way of fine tuning the angle as long as it gives sufficient hold. Still making good use of your supply of cherry I see, looks nice.

The curve of the bit and shape of the axe remind me of Austrian axe makers Mueller and Stubai. The vertical lines in the grind pattern remind me of Solingen and other Rhine axe makers.

The word you need to look for is Hirsch = Deer. That leaves a lot of possibilities, but after searching i've find this:

https://www.holzwerken.de/museum/hersteller/hirsch.phtml

So its a Gebrüder Busch axe from Remscheid.

Gebrüder = Brothers

Busch = Bush

The Bush Brothers is kind of cool sounding

You have your work all set out in front of you lapping that back-side. Have so much fun