- Joined

- Aug 21, 2013

- Messages

- 3,898

I find the old-school collared Finnish/Swedish/Karelian axes pretty interesting. I know most of the forum members who post here are primarily interested in American patterns and their histories. There seems to have been three major producers of axes/steel tools in Finland: Strömfors, Kellokoski-Mariefors, and the Billnäs Ironworks. I guess that a way to approach it is: 1) Notable makers, 2) Patterns, 3) Head/Bit construction, 4) History, and 5) Handles/Hafting.

I invite anyone who can add pictures, information, history, their own stories, or make corrections/clarify if you see something you know is out of line (Jake Pogg ). I should probably post the links that I used to find this info and where the pictures came from but I started snagging the photos for my own reference to the models and only later thought of posting it here and dont have all of them saved.

If you read this and your picture was lifted and posted here and you want it removed please just say so and it will be done.

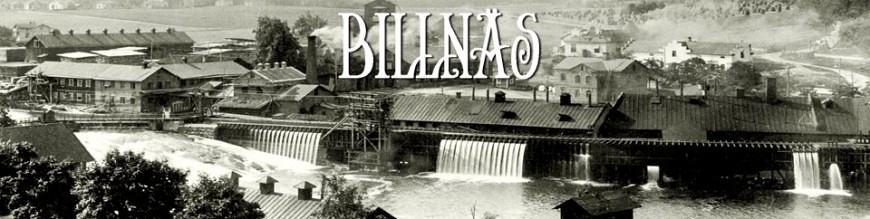

This is a quick rundown of the Billnäs Ironworks history in regards to traditional Finnish axes. The following is translated from Finnish using Google chrome then combed through to align the syntax, morphology, and semantics to make it read easier in English while staying true to the intended message as far as I can tell from Finnish while not speaking it.

https://probillnas.fi/historia/ - Village of Billnäs homepage.

BILLNÄS'S HISTORY

Ruukki establishment of the Mustio river beach

In June 1641 Finland received, from the Mountain Master Carl Sten, a construction bill authorizing the construction of an ironworks in the Northern Administration, at the village of Mustio, on the second lowest set of rapids. There was already a water mill established at the location.

Time and space were favorable for the establishment of the ironworks in the remoteness of Billnäs, Finland. The Swedish-Finnish Empire was spectacular, ranging to Central Europe. The 30-Year War made iron sought after and an expensive raw material. On the other hand this changed the country and brought them to more efficient methods of iron production. Already present in Belgium and northern France the areas shifted skilled blacksmiths, blast furnace, and coal burners.

The Billnäs ironworks operation at this location was acceptable. Interrupting the Mustio Rivers flow at Billnäs was a rock precipice of more than 6 m high rock - large enough that dam structures were not needed. Transport links were good: the ironworks passed through the Turku and Vyborg that joined the Great Coastal Road (now called the "King Road"). This was located near the Pohjanpitäjänlahti Bay at the Skuru Harbor through which iron ore was transported and prepared. The surroundings provided plenty of forests; wood needed for iron smelting and the manufacture of coal used in forging.

Ironing out the initial steps in Billnäs

Ruukki was originally part of a blast furnace and Bar hammer. A blast furnace, in which iron ore is melted takkiraudaksi (Iron alloy of 4-5% carbon) was located next to Karjaanjoki River Maasilta (bridge?) The Hammer Smithy ironworks area refined the pig iron, making it stronger.

Billnäs was only the fourth industrial ironworks in Finland (it was preceded by Suitia, Antskog and Mustio). All four ironworks were founded upon Lohja found in the Ojamosta iron ore deposits. However, Ojamo ore turned out to be low quality. In the 1600s to mid-early 1800s nearly all Finnish ironworks used ore brought in from Sweden.

The location of the blast furnace was poorly chosen, and was finally destroyed by the flooding caused by tired masuunipadon peasants in 1659, it was established to replace the Fagervik ironworks, Inkoo 1646 and the Skogby ironworks, and Hankoniemi in1682. Up until 1883, these three ironworks belonged to the same company.

The Great Plague (1700-21), this was a difficult time for Finland and its young industry. Ironworks stood empty and dilapidated, the Russians looted their contents, and the plague devastated the country and killed Ruukki municipalitys population.

Booms and Setbacks

A new boom began, when all three ironworks were transferred to Hising (crowned Hisinger) - owned by the family in 1723. With the Billnäs River on both sides of the beach they build the new Bar hammer ahjoineen and kookkaine waterwheels, and the large coal room. In particular, Johan Hisinger was a hard-working builder who more clearly than anyone else has left its mark on these ironworks building stock. The forged iron initials JH still speak to his endeavors. Johan Hisinger also developed the agricultural Ironworks and established their connection with the gardens and farm tool industry. Finland's first potatoes were cultivated in Fagervik, so this novelty was known early in the Billnäs area.

The Billnäs ironworks on the oldest part of the north bank of the river was destroyed by fire in 1775. The fire spared only the two small residential building, located in a sheltered area hidden next to the cliffs. They are now the oldest buildings in Billnäs. Ruukki's current infrastructure was created after the construction of the fire.

In the mid-1800s there were reforms that resulted in increases in the Billnäs Ironworks' main product of pig iron. In addition, forged nails, axes, shovels, horseshoes and shipping guarantees. Products sold particularly to Tallinn and other cities of the southern shore of the Gulf of Finland and St. Petersburg; domestic demand was lower. The villages first ironworks mansion, Villa Billnäs, a wooden structure was built in 1882.

The future of the old Billnäs Ironworks was, like most of the other ironworks in our country, under attack in the early 1880s. Old fashioned production methods were not able to compete with large European and American factories, and their activities gradually faded away .

A new kind of mass production took hold and more focus on furniture building.

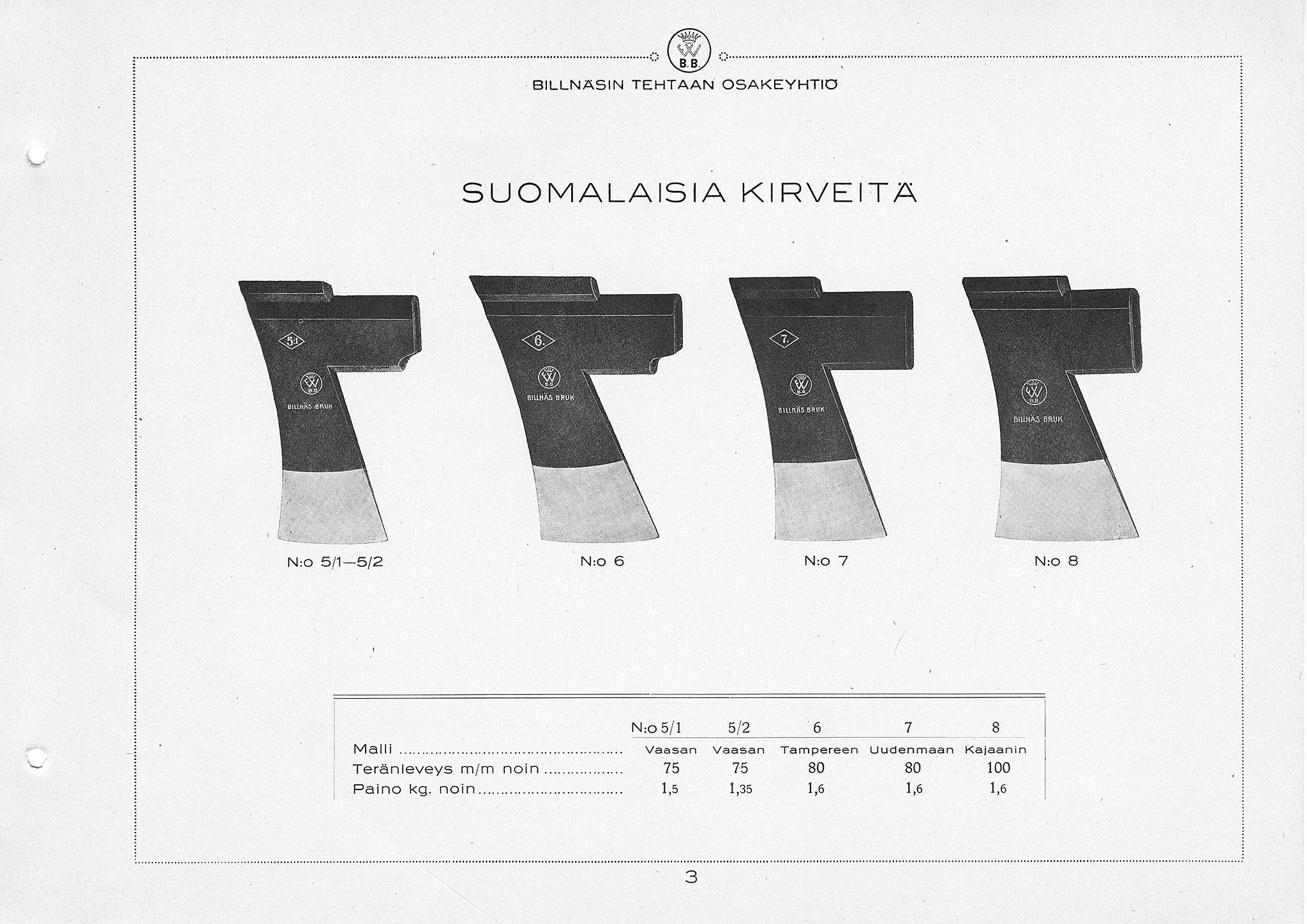

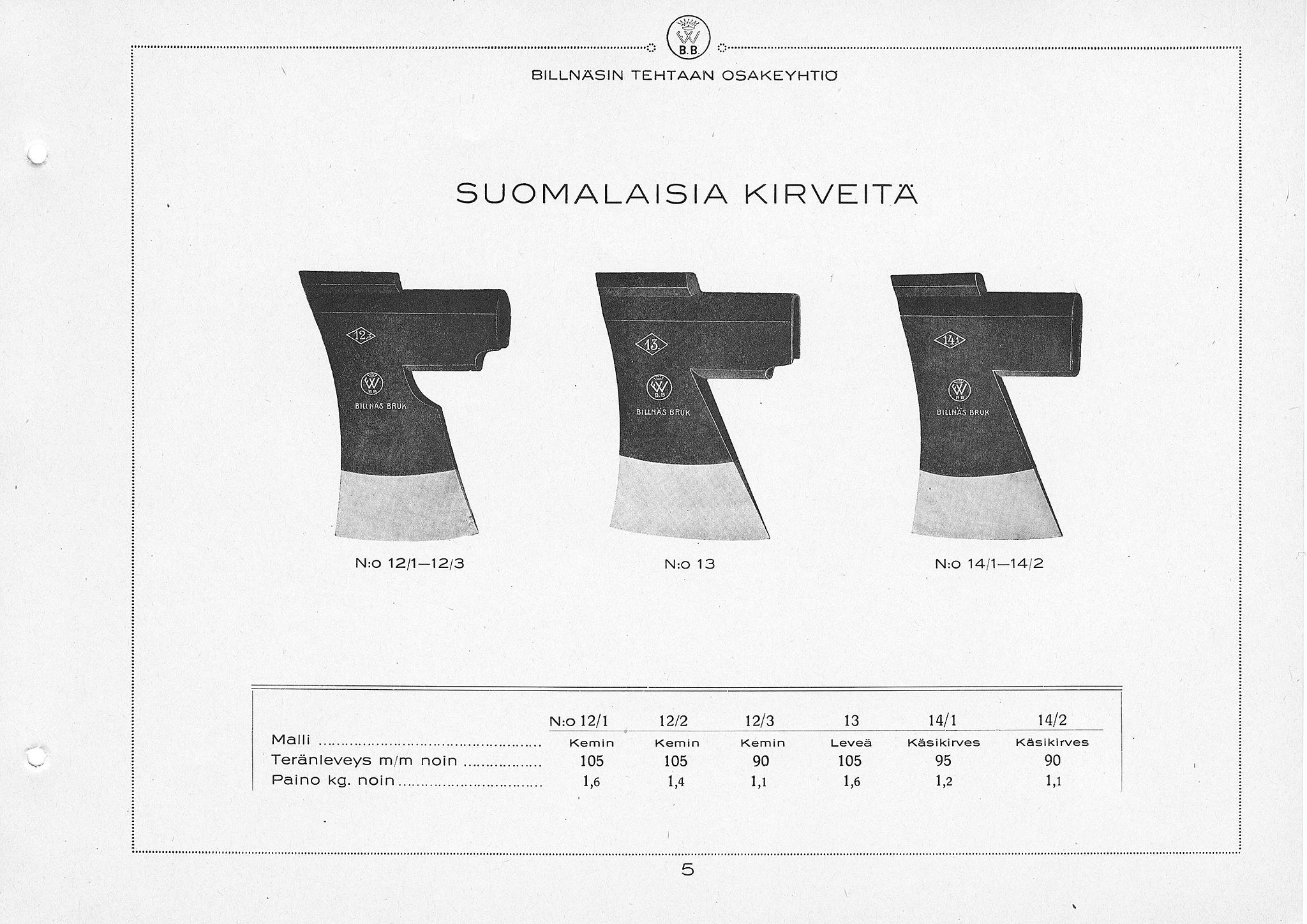

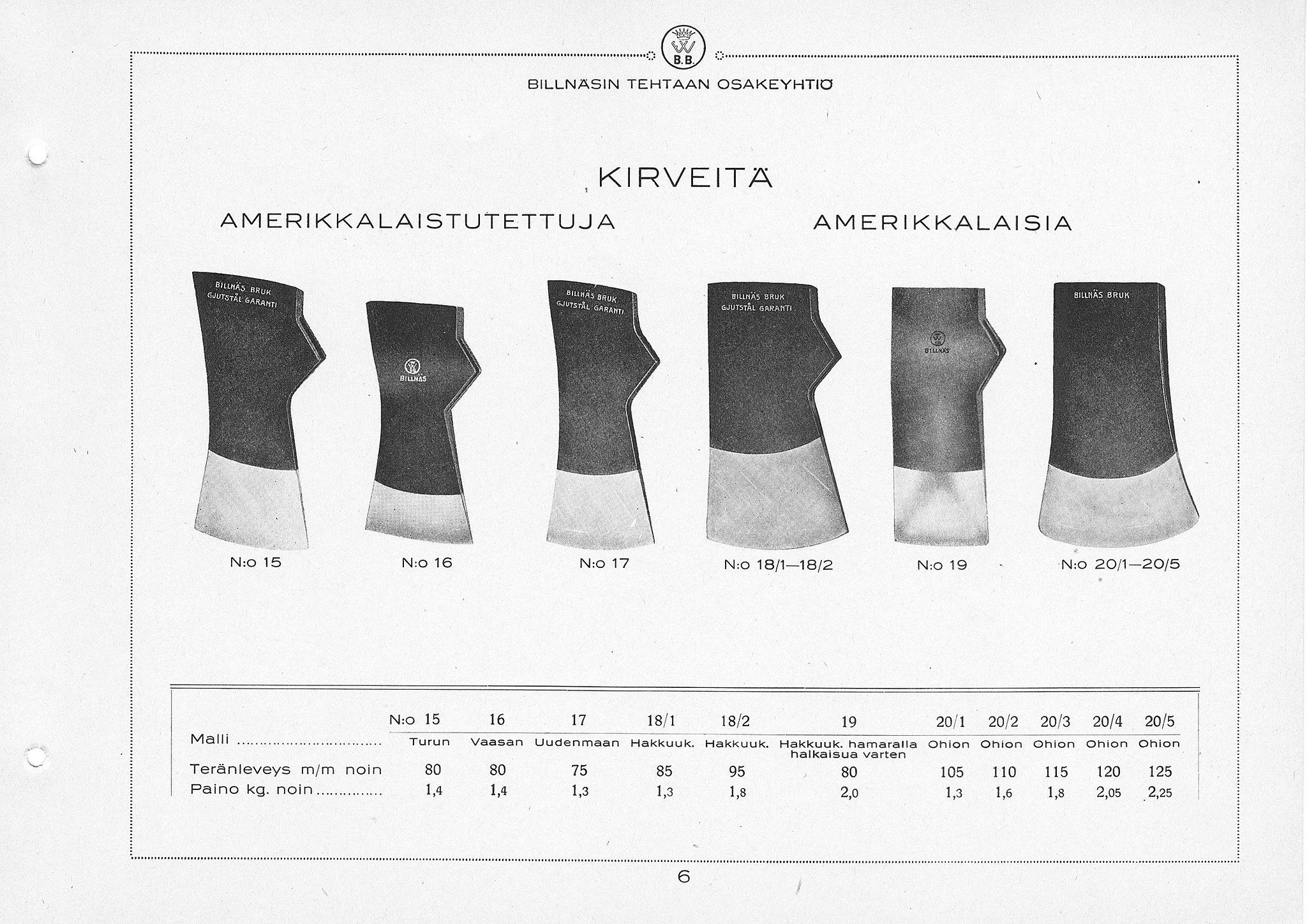

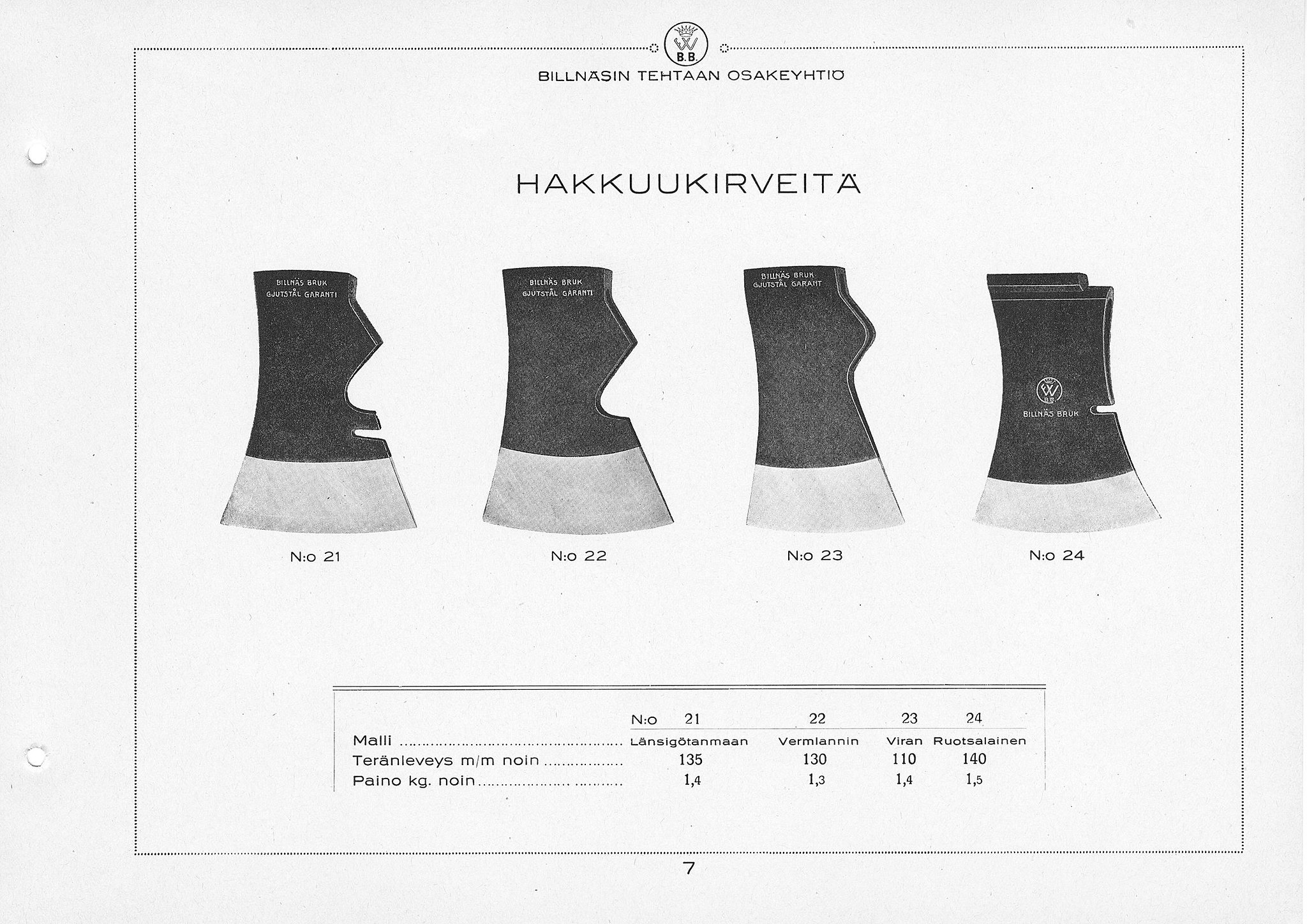

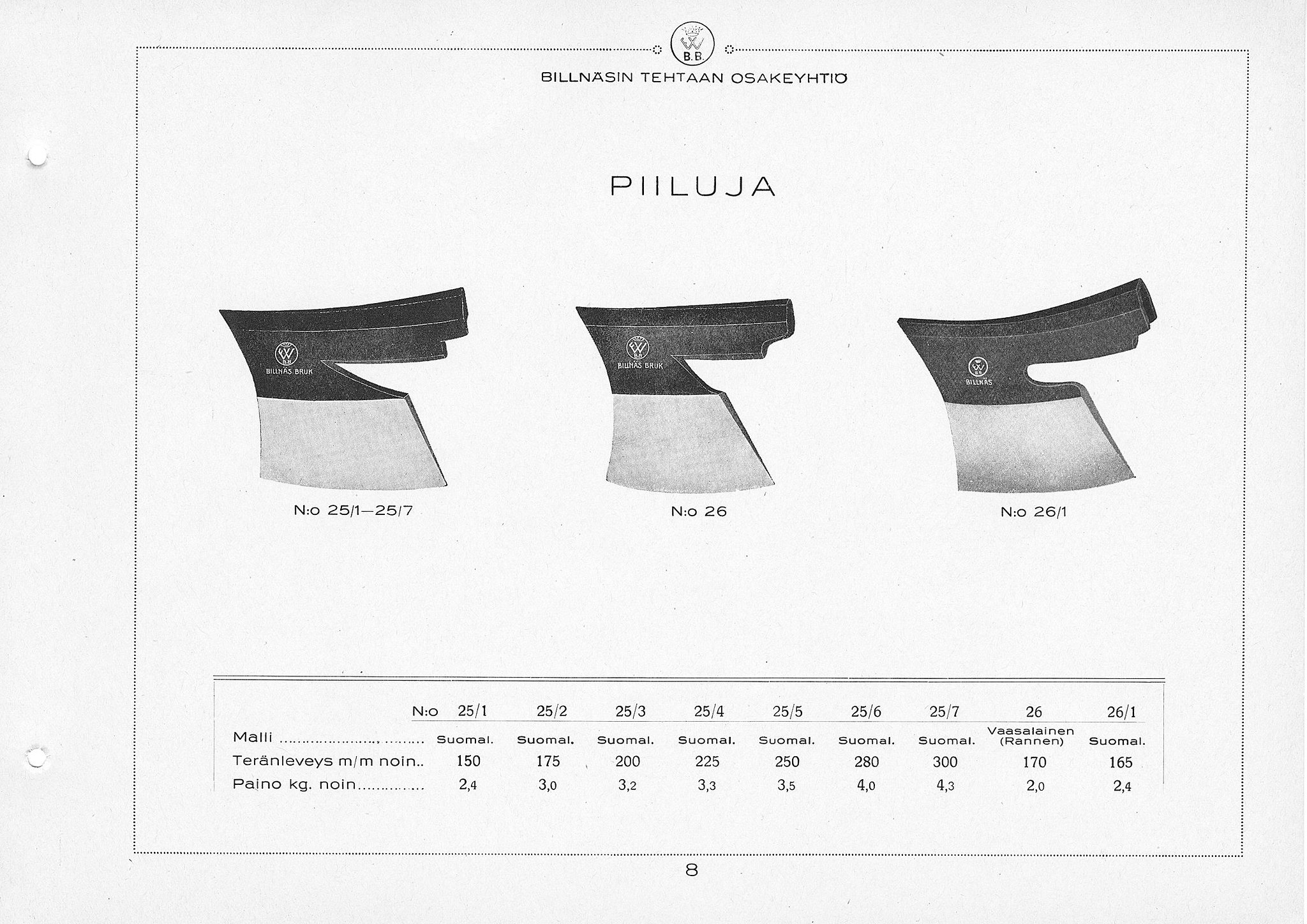

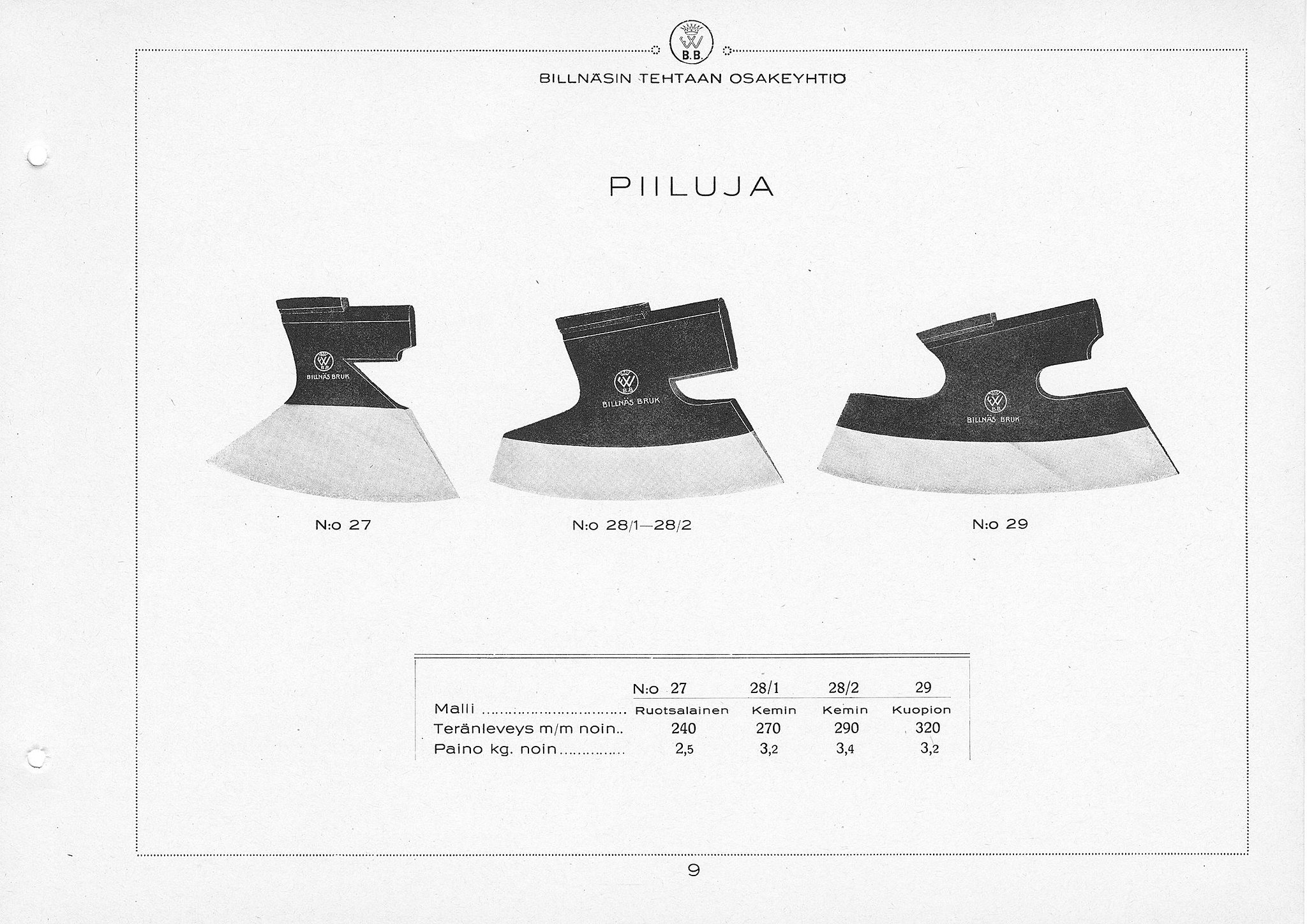

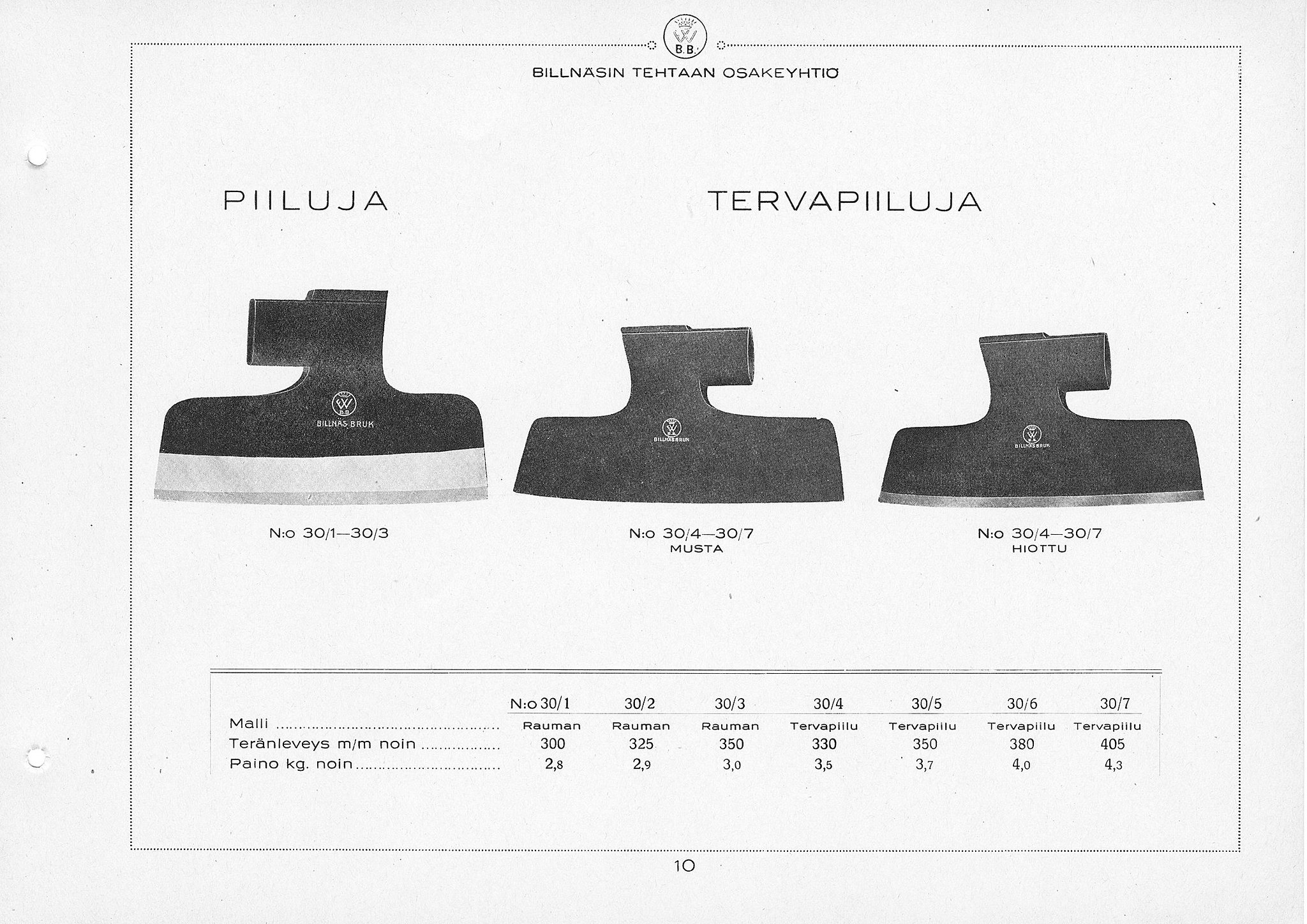

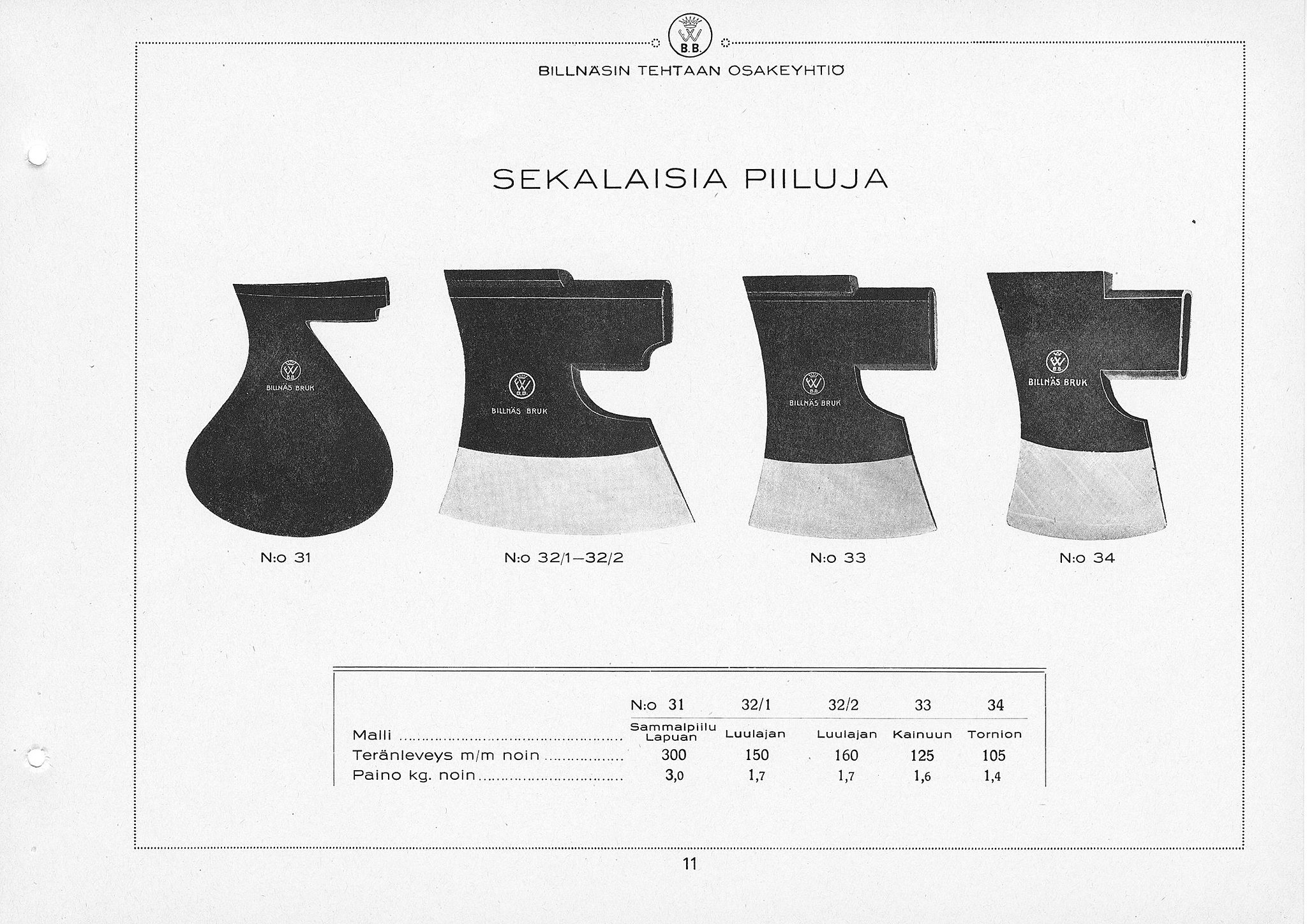

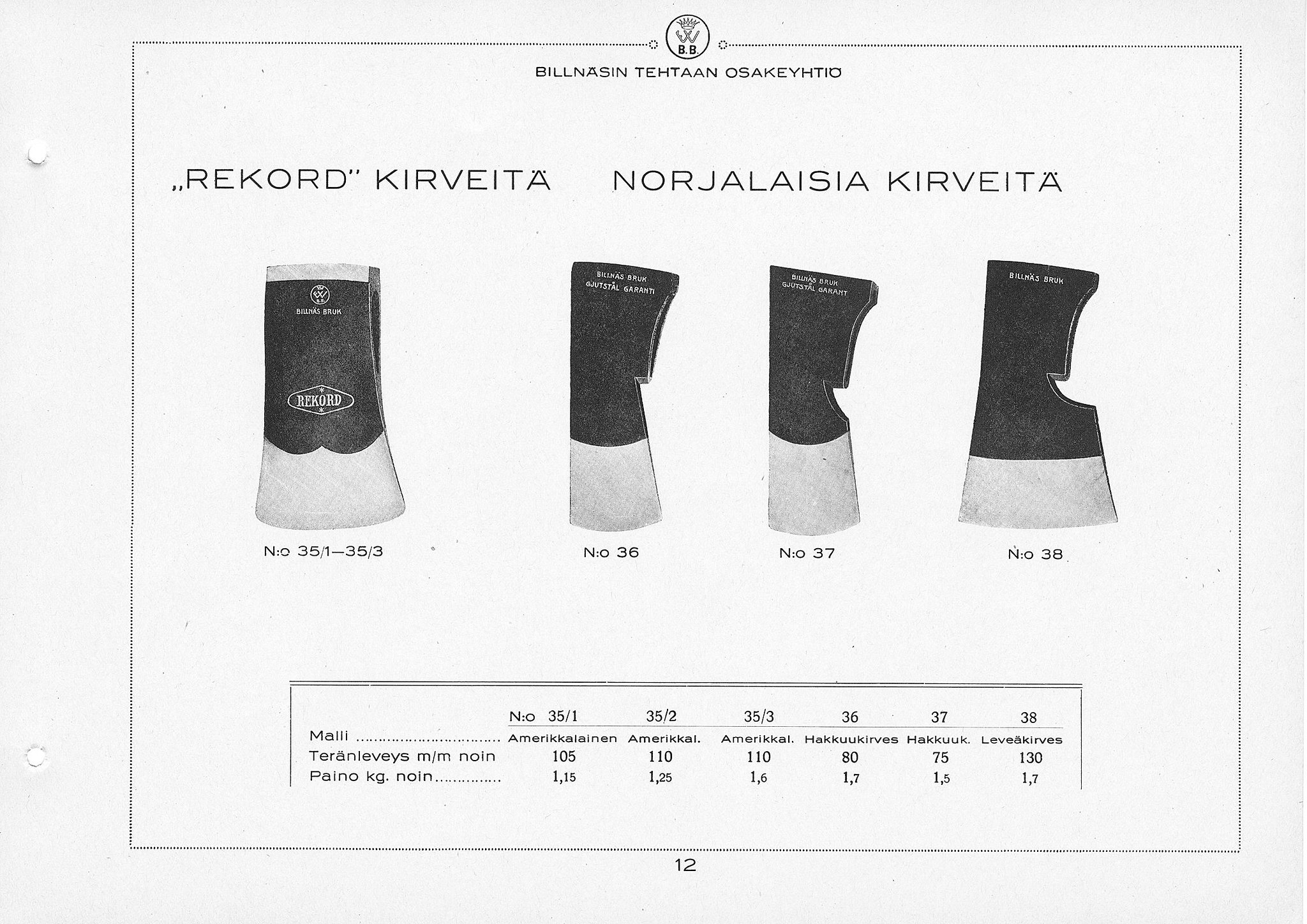

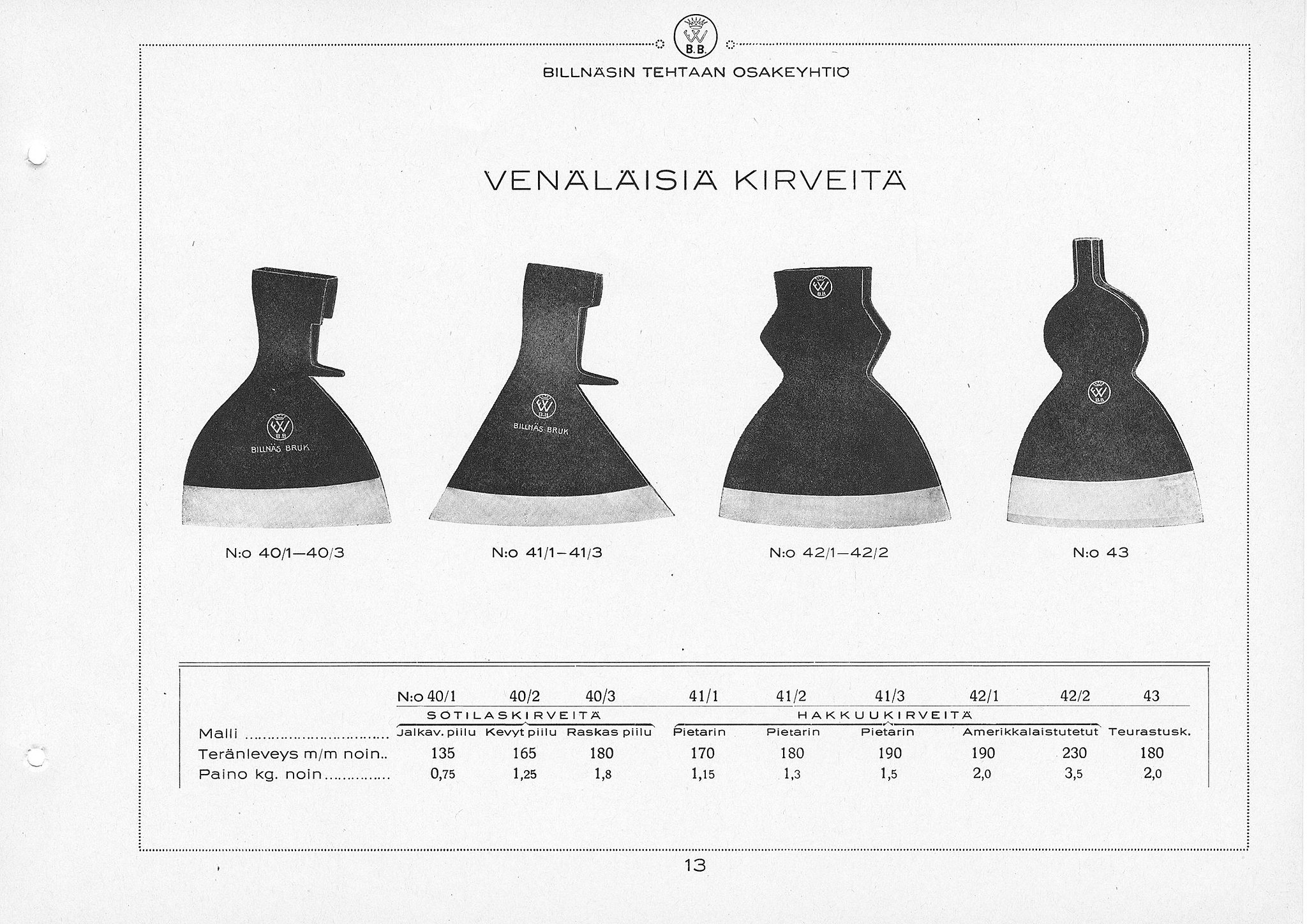

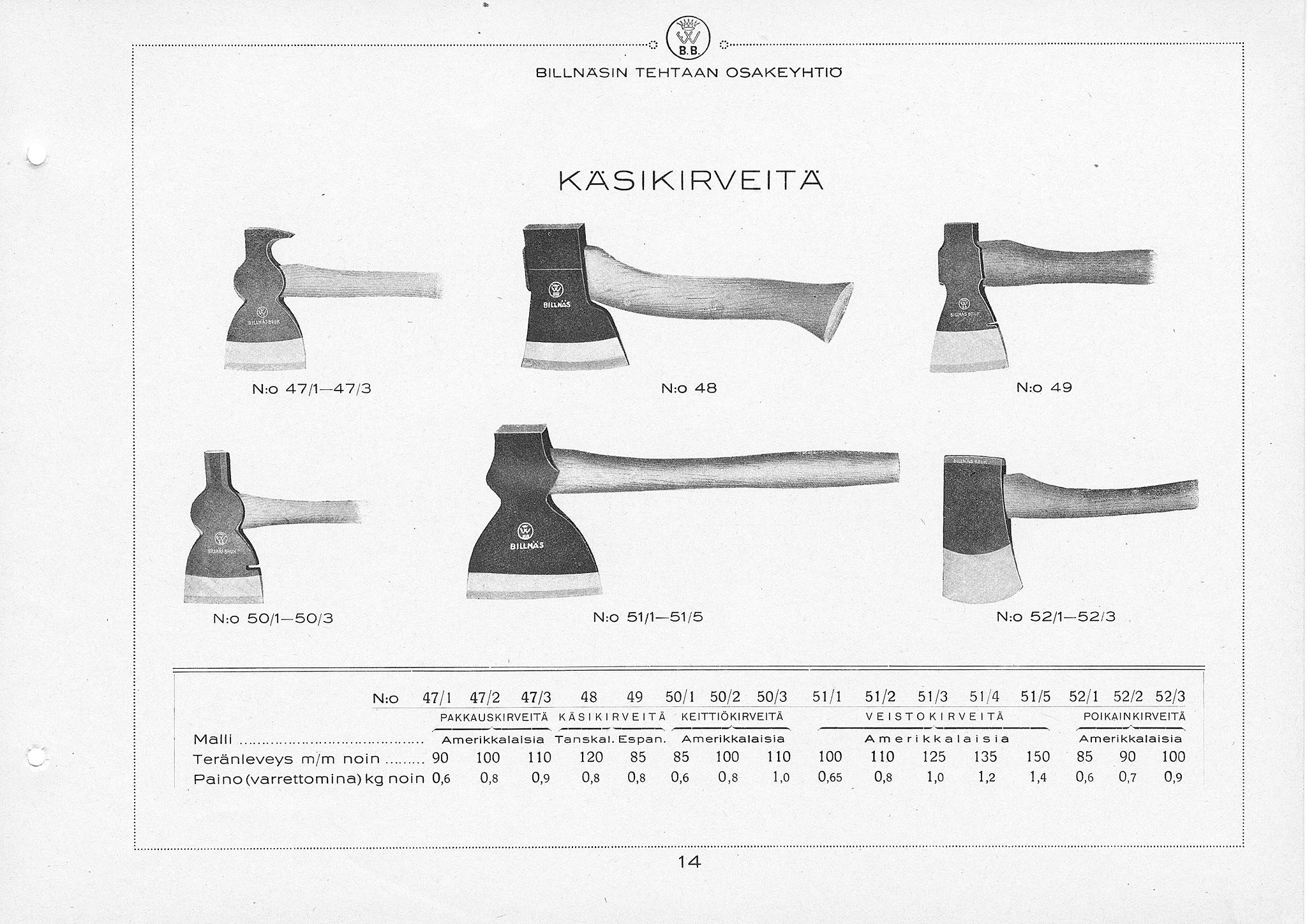

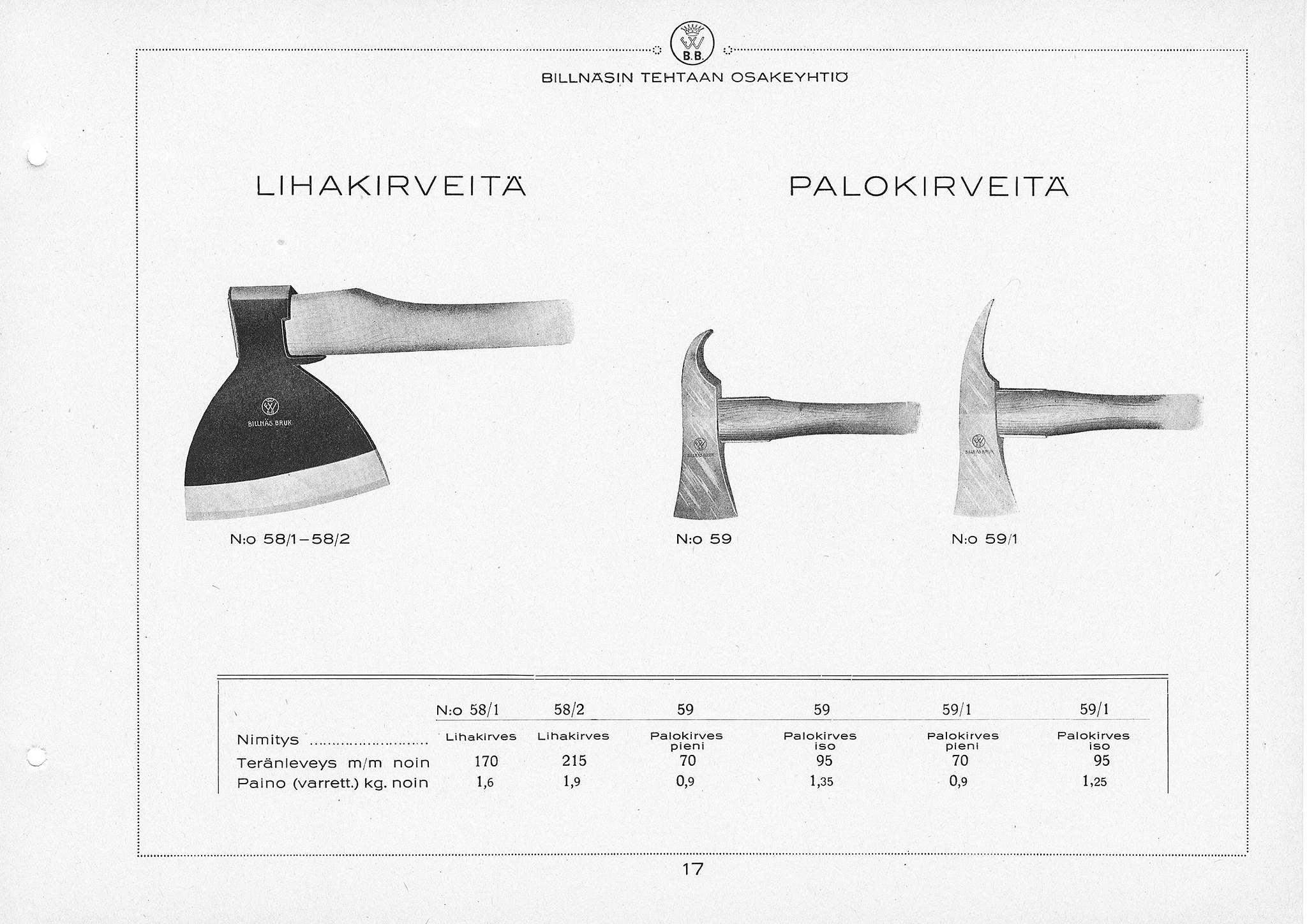

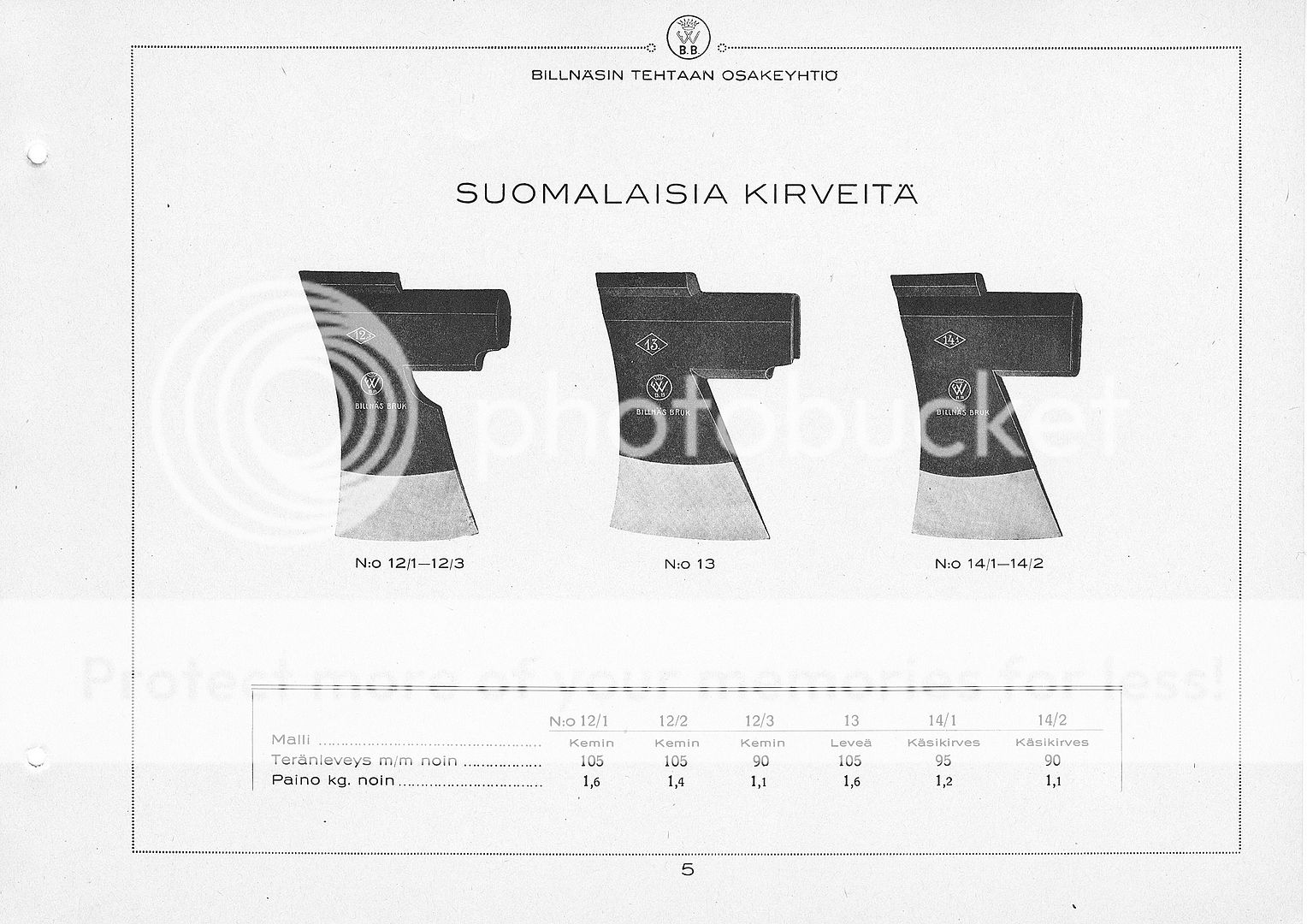

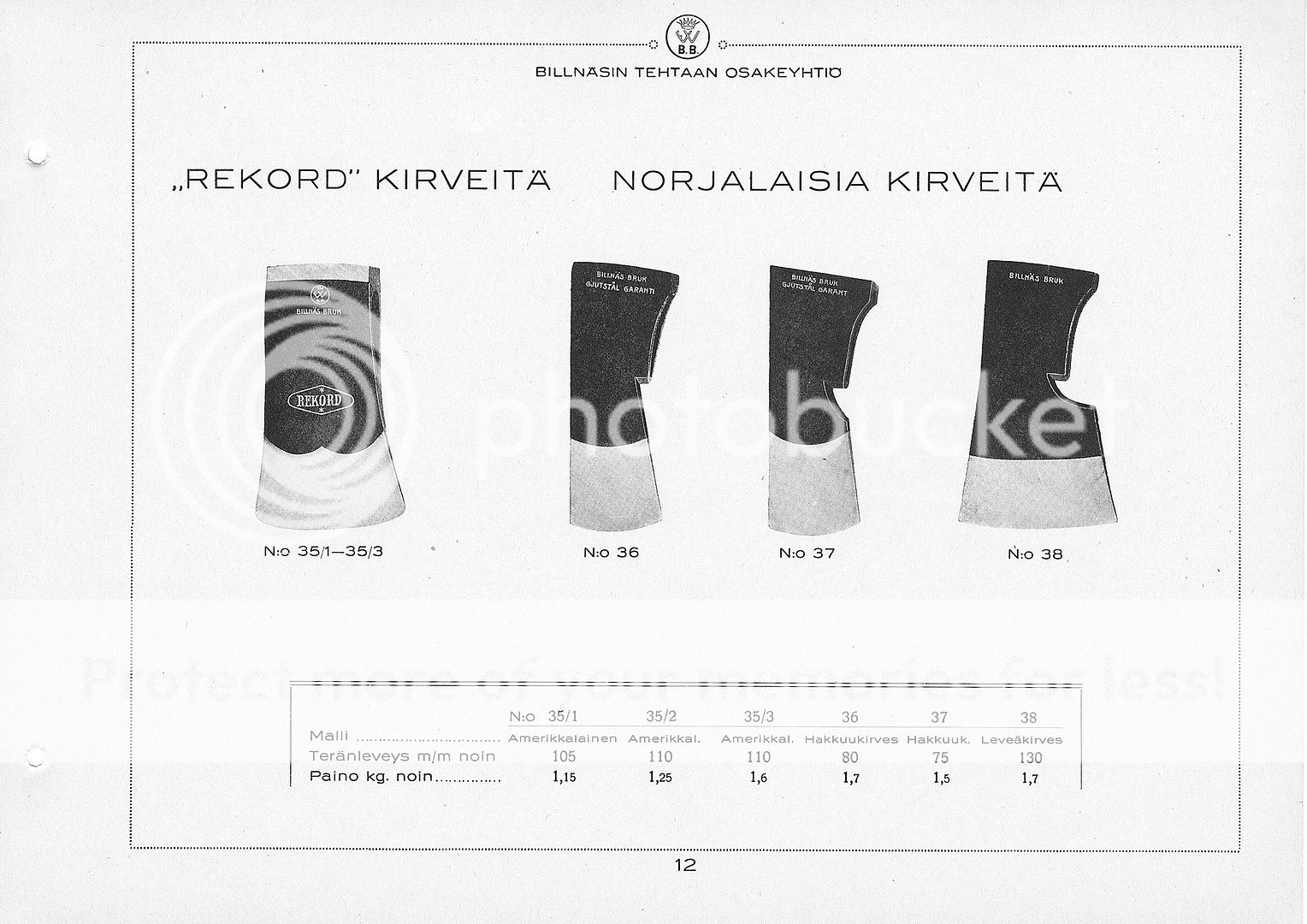

Billnäs savior turned out to be an engineer, and later CEO Fridolf Hisinger Leopold, who was owner of the ironworks in 1883. As the lively construction season began, the focus of production ushered in a new era. On the site of the old workshops rose an industrial plant, which was prepared by mass-production in the country by new technology and methods. Door handles, axes (in the 1890s up to 40 different models), hammers, pickaxes, Kihveli, etc. The products soon earned a good reputation and production volumes grew steadily. In particular, the larger tool orders went to the Russian army and led Billnäs ironworks to a new golden age. In the peak of the year in 1915, the Ironworks employed 1,072 employees.

Large-scale office furniture manufacturing in the Ironworks was started in 1909. American models produced from Polish oak via Billnäs furniture became a standard throughout the country. Manufacture of furniture did not end until the 1950s.

The wooden ironworks mansion burned down in 1915, with a large part of the ironworks, also was lost the record archives. The current "stone castle" Villa Billnäs was built on the same stone footings.

Fiskars company time

After the First World War, the ironworks export connections to the east broke down and the main market area became domestic. In 1920, Billnäs Ironworks was incorporated into the Fiskars Corporation, and such. Tool manufacturing continued in the old halls. Further Fiskars modern production facilities on the outskirts of the old iron works produced world-renowned scissors among other implements.

The next major breakthrough in the history of Billnäs ironworks began in the late 1970s, with the heavy metal industry, and employment fell drastically bottom. The old ironworks buildings are no longer used in modern industry, ironworks and industrial activity dried up in the mid-1980s. Historical precedent threatened to disappear due to inactivity brought about by decay.

Preservation and development of Ruukki create the perfect setting for renewal.

1983, The Municipality in the North established a company named Kiint. North Ruukki Oy Industry. State aid allowed the company to acquire the essential elements of the Billnäs and Fiskars Ironworks, a total of more than 110 buildings, of which about 60 were Billnäs. The company's main objective was defined as cultural and historical preservation of valuable ironworks milieus and diversified development of municipal businesses. The company has throughout its existence struggled with financial difficulty, but still sought to implement its allocated target. In recognition of the preservation of cultural heritage, Ruukki Industrial Company was awarded the prestigious "Europa Nostra" award in 1988. The work to develop the ironworks sites and to preserve the architectural heritage is still on going.

Billnäs - A lively village

Billnäs Ironworks is gradually regaining its position in the region, as an operational and cultural focus. Manufacturing companies operating in the area of opportunities (Fiskars and Fundia) thanks to Ruukki have retained its original industrial character. Frustrated survivors of the premises changed with the new companies, for example. Building a pharmacy, they have enhanced the overall look of the ironworks.

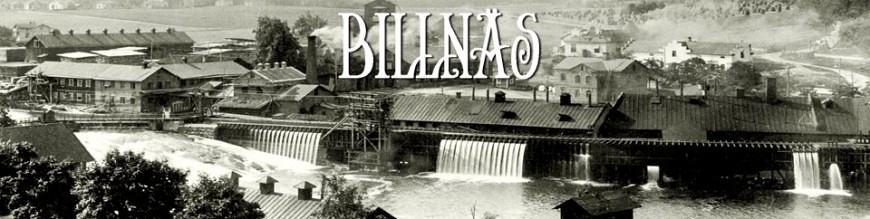

Billnäs Ironworks photos

I invite anyone who can add pictures, information, history, their own stories, or make corrections/clarify if you see something you know is out of line (Jake Pogg ). I should probably post the links that I used to find this info and where the pictures came from but I started snagging the photos for my own reference to the models and only later thought of posting it here and dont have all of them saved.

If you read this and your picture was lifted and posted here and you want it removed please just say so and it will be done.

This is a quick rundown of the Billnäs Ironworks history in regards to traditional Finnish axes. The following is translated from Finnish using Google chrome then combed through to align the syntax, morphology, and semantics to make it read easier in English while staying true to the intended message as far as I can tell from Finnish while not speaking it.

https://probillnas.fi/historia/ - Village of Billnäs homepage.

BILLNÄS'S HISTORY

Ruukki establishment of the Mustio river beach

In June 1641 Finland received, from the Mountain Master Carl Sten, a construction bill authorizing the construction of an ironworks in the Northern Administration, at the village of Mustio, on the second lowest set of rapids. There was already a water mill established at the location.

Time and space were favorable for the establishment of the ironworks in the remoteness of Billnäs, Finland. The Swedish-Finnish Empire was spectacular, ranging to Central Europe. The 30-Year War made iron sought after and an expensive raw material. On the other hand this changed the country and brought them to more efficient methods of iron production. Already present in Belgium and northern France the areas shifted skilled blacksmiths, blast furnace, and coal burners.

The Billnäs ironworks operation at this location was acceptable. Interrupting the Mustio Rivers flow at Billnäs was a rock precipice of more than 6 m high rock - large enough that dam structures were not needed. Transport links were good: the ironworks passed through the Turku and Vyborg that joined the Great Coastal Road (now called the "King Road"). This was located near the Pohjanpitäjänlahti Bay at the Skuru Harbor through which iron ore was transported and prepared. The surroundings provided plenty of forests; wood needed for iron smelting and the manufacture of coal used in forging.

Ironing out the initial steps in Billnäs

Ruukki was originally part of a blast furnace and Bar hammer. A blast furnace, in which iron ore is melted takkiraudaksi (Iron alloy of 4-5% carbon) was located next to Karjaanjoki River Maasilta (bridge?) The Hammer Smithy ironworks area refined the pig iron, making it stronger.

Billnäs was only the fourth industrial ironworks in Finland (it was preceded by Suitia, Antskog and Mustio). All four ironworks were founded upon Lohja found in the Ojamosta iron ore deposits. However, Ojamo ore turned out to be low quality. In the 1600s to mid-early 1800s nearly all Finnish ironworks used ore brought in from Sweden.

The location of the blast furnace was poorly chosen, and was finally destroyed by the flooding caused by tired masuunipadon peasants in 1659, it was established to replace the Fagervik ironworks, Inkoo 1646 and the Skogby ironworks, and Hankoniemi in1682. Up until 1883, these three ironworks belonged to the same company.

The Great Plague (1700-21), this was a difficult time for Finland and its young industry. Ironworks stood empty and dilapidated, the Russians looted their contents, and the plague devastated the country and killed Ruukki municipalitys population.

Booms and Setbacks

A new boom began, when all three ironworks were transferred to Hising (crowned Hisinger) - owned by the family in 1723. With the Billnäs River on both sides of the beach they build the new Bar hammer ahjoineen and kookkaine waterwheels, and the large coal room. In particular, Johan Hisinger was a hard-working builder who more clearly than anyone else has left its mark on these ironworks building stock. The forged iron initials JH still speak to his endeavors. Johan Hisinger also developed the agricultural Ironworks and established their connection with the gardens and farm tool industry. Finland's first potatoes were cultivated in Fagervik, so this novelty was known early in the Billnäs area.

The Billnäs ironworks on the oldest part of the north bank of the river was destroyed by fire in 1775. The fire spared only the two small residential building, located in a sheltered area hidden next to the cliffs. They are now the oldest buildings in Billnäs. Ruukki's current infrastructure was created after the construction of the fire.

In the mid-1800s there were reforms that resulted in increases in the Billnäs Ironworks' main product of pig iron. In addition, forged nails, axes, shovels, horseshoes and shipping guarantees. Products sold particularly to Tallinn and other cities of the southern shore of the Gulf of Finland and St. Petersburg; domestic demand was lower. The villages first ironworks mansion, Villa Billnäs, a wooden structure was built in 1882.

The future of the old Billnäs Ironworks was, like most of the other ironworks in our country, under attack in the early 1880s. Old fashioned production methods were not able to compete with large European and American factories, and their activities gradually faded away .

A new kind of mass production took hold and more focus on furniture building.

Billnäs savior turned out to be an engineer, and later CEO Fridolf Hisinger Leopold, who was owner of the ironworks in 1883. As the lively construction season began, the focus of production ushered in a new era. On the site of the old workshops rose an industrial plant, which was prepared by mass-production in the country by new technology and methods. Door handles, axes (in the 1890s up to 40 different models), hammers, pickaxes, Kihveli, etc. The products soon earned a good reputation and production volumes grew steadily. In particular, the larger tool orders went to the Russian army and led Billnäs ironworks to a new golden age. In the peak of the year in 1915, the Ironworks employed 1,072 employees.

Large-scale office furniture manufacturing in the Ironworks was started in 1909. American models produced from Polish oak via Billnäs furniture became a standard throughout the country. Manufacture of furniture did not end until the 1950s.

The wooden ironworks mansion burned down in 1915, with a large part of the ironworks, also was lost the record archives. The current "stone castle" Villa Billnäs was built on the same stone footings.

Fiskars company time

After the First World War, the ironworks export connections to the east broke down and the main market area became domestic. In 1920, Billnäs Ironworks was incorporated into the Fiskars Corporation, and such. Tool manufacturing continued in the old halls. Further Fiskars modern production facilities on the outskirts of the old iron works produced world-renowned scissors among other implements.

The next major breakthrough in the history of Billnäs ironworks began in the late 1970s, with the heavy metal industry, and employment fell drastically bottom. The old ironworks buildings are no longer used in modern industry, ironworks and industrial activity dried up in the mid-1980s. Historical precedent threatened to disappear due to inactivity brought about by decay.

Preservation and development of Ruukki create the perfect setting for renewal.

1983, The Municipality in the North established a company named Kiint. North Ruukki Oy Industry. State aid allowed the company to acquire the essential elements of the Billnäs and Fiskars Ironworks, a total of more than 110 buildings, of which about 60 were Billnäs. The company's main objective was defined as cultural and historical preservation of valuable ironworks milieus and diversified development of municipal businesses. The company has throughout its existence struggled with financial difficulty, but still sought to implement its allocated target. In recognition of the preservation of cultural heritage, Ruukki Industrial Company was awarded the prestigious "Europa Nostra" award in 1988. The work to develop the ironworks sites and to preserve the architectural heritage is still on going.

Billnäs - A lively village

Billnäs Ironworks is gradually regaining its position in the region, as an operational and cultural focus. Manufacturing companies operating in the area of opportunities (Fiskars and Fundia) thanks to Ruukki have retained its original industrial character. Frustrated survivors of the premises changed with the new companies, for example. Building a pharmacy, they have enhanced the overall look of the ironworks.

Billnäs Ironworks photos

Last edited: