Hey Folks,

Long time listener, first time caller. My name is Trevor, and I am a Bladeaholic.

Bottom Line up front: I am building a forging press with my electrical engineer father and would appreciate some confirmation on some key components of the press I am building.

I plan to build a 24.5/25 Ton Press based of Jim Batson's book and data breakdown.

I have a 5" diameter x 8" stroke cylinder and a 10 Gallon tank thus far.

I am considering this motor (Which is one Redbeard Ops recommended I believe)

and this control valve:

I was pretty confident that I had selected appropriate components but when I reached out to Vevor they responded with "We checked with the technicians and found out that this product is only for air compressors and is not recommended for use with other equipment."

I would appreciate relevant data from the hive as to whether they will work or not.

Thanks in advance,

T

Long time listener, first time caller. My name is Trevor, and I am a Bladeaholic.

Bottom Line up front: I am building a forging press with my electrical engineer father and would appreciate some confirmation on some key components of the press I am building.

I plan to build a 24.5/25 Ton Press based of Jim Batson's book and data breakdown.

I have a 5" diameter x 8" stroke cylinder and a 10 Gallon tank thus far.

I am considering this motor (Which is one Redbeard Ops recommended I believe)

VEVOR 5HP SPL Air Compressor Motor, 230V 15 Amps Electric Motor, 3450RPM 56 Frame, 5/8" Keyed Shaft, 1.88" Shaft Length for Air Compressors, CW/CCW Rotation at (https://www.vevor.com/single-phase-...utm_term=4587368679089580&utm_content=其它品类-PC)

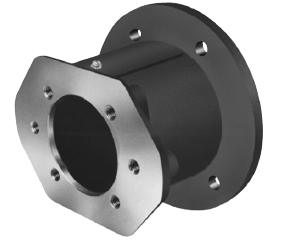

and this pump:VEVOR Hydraulic Log Splitter Pump, 11GPM, 2 Stage 3000PSI Wood Log Splitter Pump, 1'' Inlet 1/2'' NPT Outlet 3600 RPM Aluminum Hydraulic Gear Pump, for Small Engine Mounting Log Splitters Snowplow

and this control valve:

VEVOR Hydraulic Valve 2 Spool Hydraulic Joystick Control Valve 11gpm Hydraulic Directional Control Valve Double Acting for Tractors Loaders Tanks. https://www.vevor.com/hydraulic-con...alve-tractor-loader-w-joystick-p_010416714851

I was pretty confident that I had selected appropriate components but when I reached out to Vevor they responded with "We checked with the technicians and found out that this product is only for air compressors and is not recommended for use with other equipment."

I would appreciate relevant data from the hive as to whether they will work or not.

Thanks in advance,

T