I posted this in shop talk but think it is better suited here.

Its been rattling around in my head for the last year and a half.

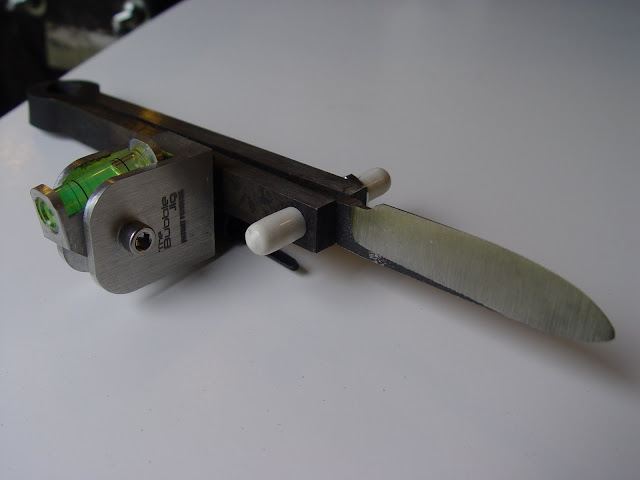

How can this jig be used to grind folding knife blades?

I talked with numerous folder makers, looking for some insight into grinding folder blades. Each person had their own approach; with no standard method used by everyone.

I had already dismissed using the tip of the clamp to hold the blade; moving the bubble to the side. The reason this idea was not followed up on, was I just thought "there was not enough gripping power to hold the blade motionless while grinding.

Never assume anything:thumbdn:

I profiled a couple of folder size blades of different thicknesses, one was inserted in the nose of the clamp, and the hex screw was tightened.

Not only was there no movement; I think you could hang a large ham on it without it losing its grip.

The hex bolt was exchanged for a short piece of 1/4-20 all thread; a thin nut was added, along with two thread protectors to be used as grips.

I tested steel thickness down to 1/64 inch and the clamp held them all the same. Tight!

We are shooting videos this weekend that will demonstrate grinding a folder blade along with using this set up on a horizontal disc.

So all of you Bubble Jig users; you now have a jig to help with grinding folding knife blades.

Happy grinding, Fred

Its been rattling around in my head for the last year and a half.

How can this jig be used to grind folding knife blades?

I talked with numerous folder makers, looking for some insight into grinding folder blades. Each person had their own approach; with no standard method used by everyone.

I had already dismissed using the tip of the clamp to hold the blade; moving the bubble to the side. The reason this idea was not followed up on, was I just thought "there was not enough gripping power to hold the blade motionless while grinding.

Never assume anything:thumbdn:

I profiled a couple of folder size blades of different thicknesses, one was inserted in the nose of the clamp, and the hex screw was tightened.

Not only was there no movement; I think you could hang a large ham on it without it losing its grip.

The hex bolt was exchanged for a short piece of 1/4-20 all thread; a thin nut was added, along with two thread protectors to be used as grips.

I tested steel thickness down to 1/64 inch and the clamp held them all the same. Tight!

We are shooting videos this weekend that will demonstrate grinding a folder blade along with using this set up on a horizontal disc.

So all of you Bubble Jig users; you now have a jig to help with grinding folding knife blades.

Happy grinding, Fred