BTW, a quick test to make sure that the TC leads are right is done with a magnet. The negative side on a type K thermocouple (or wire) is magnetic.

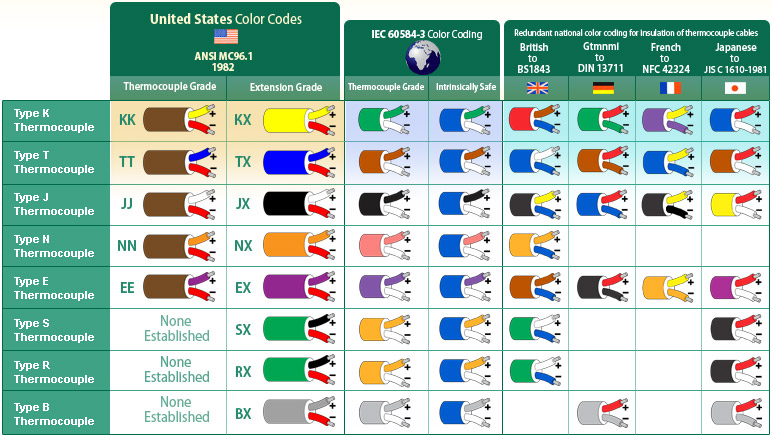

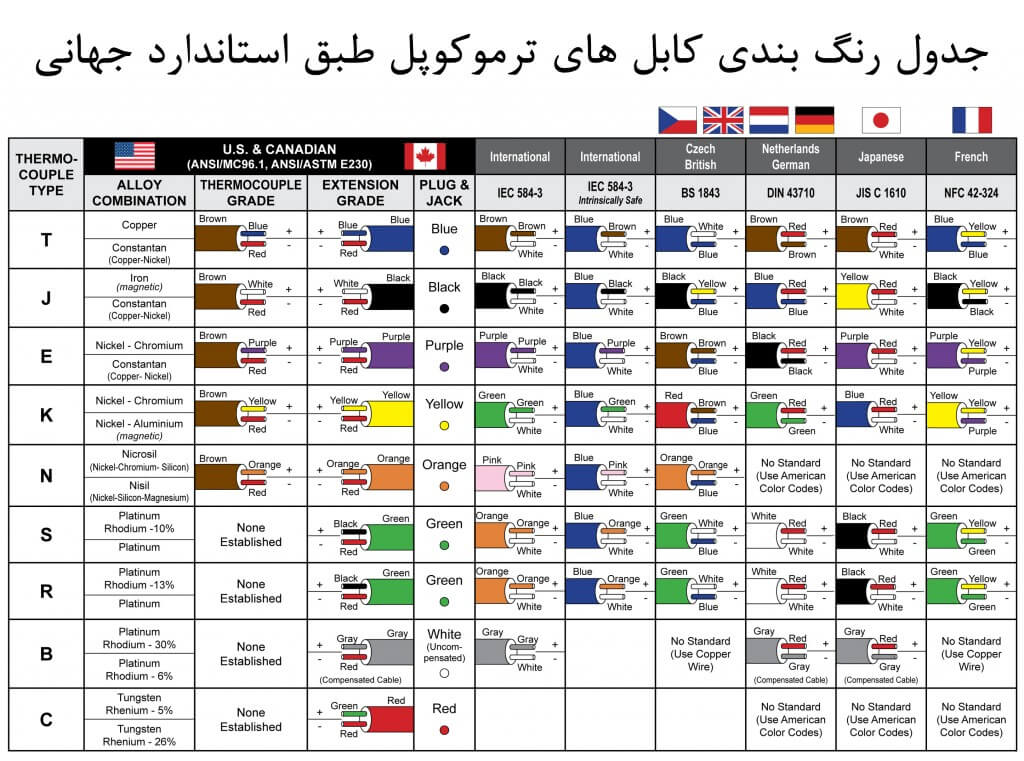

Here is an older post I made on the color codes for TC wires (

red is opposite in different parts of the world):

In type K TC wires the cover is yellow. Inside are two leads - Red is negative and yellow is positive

Thermocouples are polarized. One lead is made from alumel. It is magnetic and is the negative lead ... which connects to the red wire in type K TCs . The chromel lead is not magnetic and is positive .. thus connecting to the yellow lead.

All other plugs, sockets, and TC blocks are polarized, too. Look for the + and - marks.

This is the color code chart for TC wires:

https://www.thermocoupleinfo.com/thermocouple-color-codes.htm