- Joined

- Aug 11, 2016

- Messages

- 251

Making leather sheaths has turned out to be pretty easy, so I plan to continue to do it. I have questions, however.

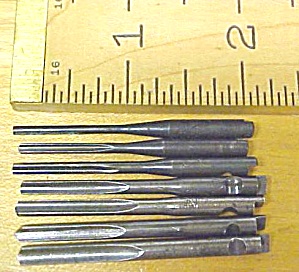

I make sheaths with 7-8-ounce leather. I use punches with multiple diamond-shaped tines to make the holes first. I am finding the friction between the thread or awl and the leather to be a pain in the butt. I have to push very hard, and it causes problems. It's really bad when I'm stitching three layers.

Am I better off using the drill press? I saw someone on Youtube saying the results would look crappy because presses tear up leather. I have a 25000-RPM Dumore drill press. Maybe it wouldn't rip the leather up the way slower ones do. I could try making the holes with a punch, which is fast, and then opening them a little with the drill press.

Another question. I'm using something called "artificial sinew" because I saw other people using it. Is there a better choice? It's like greasy dental floss, and my guess is that it's made from nylon, because you can fuse it with a lighter.

I make sheaths with 7-8-ounce leather. I use punches with multiple diamond-shaped tines to make the holes first. I am finding the friction between the thread or awl and the leather to be a pain in the butt. I have to push very hard, and it causes problems. It's really bad when I'm stitching three layers.

Am I better off using the drill press? I saw someone on Youtube saying the results would look crappy because presses tear up leather. I have a 25000-RPM Dumore drill press. Maybe it wouldn't rip the leather up the way slower ones do. I could try making the holes with a punch, which is fast, and then opening them a little with the drill press.

Another question. I'm using something called "artificial sinew" because I saw other people using it. Is there a better choice? It's like greasy dental floss, and my guess is that it's made from nylon, because you can fuse it with a lighter.