Dave, if you wanna discuss Kabar knives and designs, brother you have found the right place.

In a previous post, I said the fuller was there to reduce weight and maintain strengh, not add to it. The fuller does just that, without sharp radii, its maintains the strength. No stronger, just not any weaker.

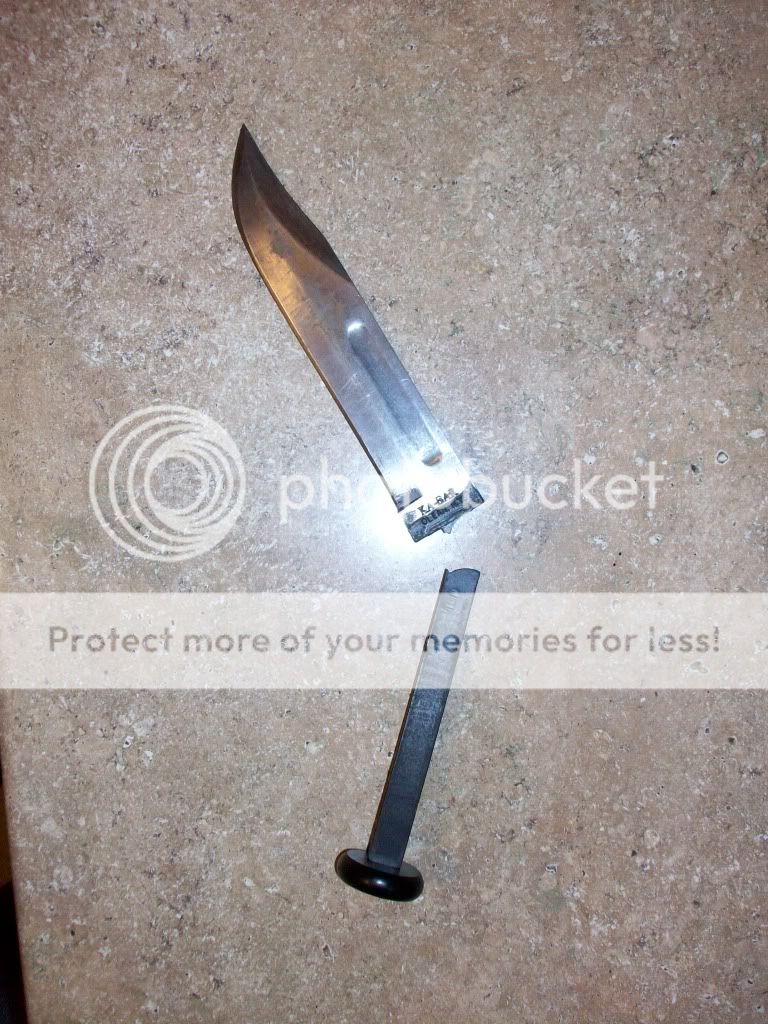

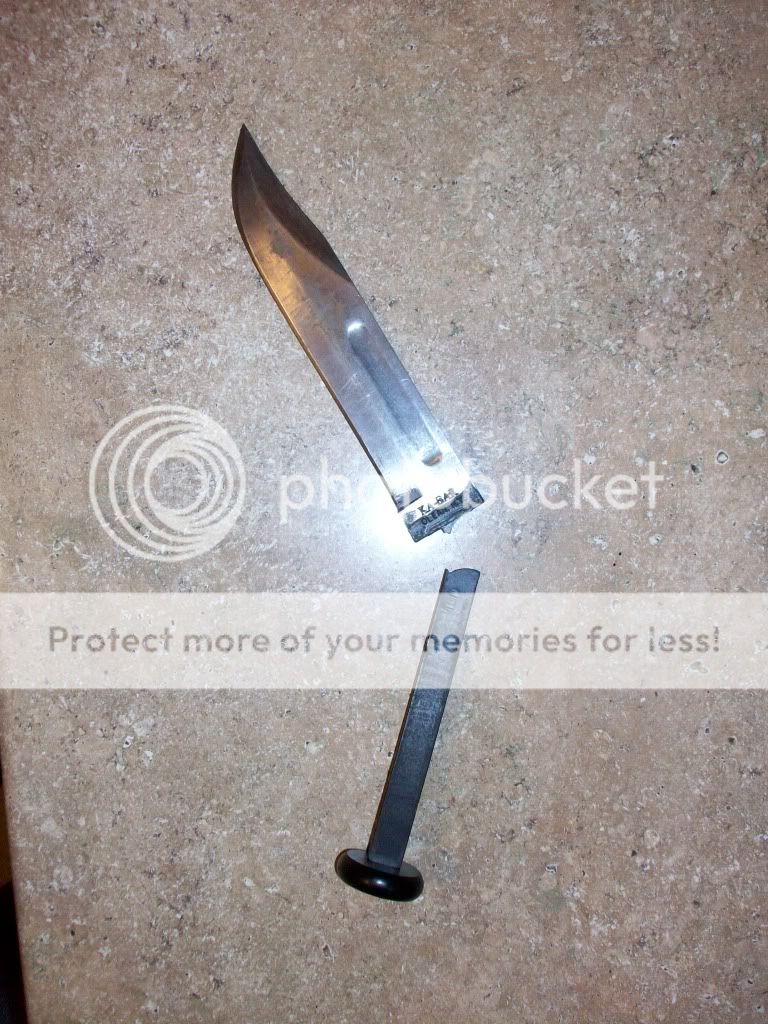

I've taken the USMC F/U knife as far as it could go. I keep this picture here,

as a reminder to help me keep somethings in perspective. I also still have the knife pieces as well.

This knife right here, was my primary one and only knife for around 3 years. When I say the only one, I mean it. I wasn't the knife knut whore that I am know, I just used what worked. And it worked.

I batoned wood. Lots of wood. Dug up rocks for bait, gut and cut animals from squirrel to deer, and everything else I killed in between. The first day I got it, I stabbed it into an empty 55 gallon drum, and twisted it until I opened a hole. Why did I do this? Not sure, I'm a little disturbed and have issues.

All the paint you see gone, is from use. Even in the fuller. That knife split every piece of hardwood that went in my wood burning stove, for 3 seasons. Every piece.

Its made hundreds of fires, from brewing tea, to warming up after a fall in the river while hiking. Bored holes in wood, chopped branches, and took probably the worst beating I've ever handed a knife, when it got it stuck in a piece of ash. There was no going back, so, me and the knife went forward.

It finally gave up the ghost one evening, when I was preparing a fire in my wood burning stove. It simply broke while being bashed with another piece of wood.

Here is the funny thing. The day it broke, I had been to Smoky Mountain Knife Works, and had just bought a brand new, Kabar 1217 USMC F/U knife. I hadn't even taken it out of the box yet, as when I got home, it was cold in the house, so, I was building a fire to warm it up.

I am a firm believer in the fact that the only reason the knife broke, was the fact that its relief had finally shown up for duty. Sounds corny, but I'm a believer in a many a strange thing. We might get into that later......

Regardless, the point of the story and pics, is that that knife in the picture was in no way shape or form, babied, at any point that I owned it. I had a Korean Vet for an uncle, and he swore that there was no better knife than the KABAR. The one he gave me, had seen war, and looked it. Still served me well for many years.

I think the one in the pic is my 3rd or 4th one. I tend to be hard on knives, and with that said, I'll still trust my life anyday, anytime, anywhere, to a Kabar Fighting/Utility knife.

So, in my next post, we can discuss some more metallurgical and magical aspect of the American Legend.

Moose