This is so cheap, it's ridiculous, but it has a very good pedigree....

Kai Luna Santoku - their listing says it's 7 in - but my measurement 6.5 in.

Most listings just say high carbon stainless steel - but Kai's website says German DIN1.4116 with 56-57HRC - not sterling (ha-ha! it's steel, sorry could not resist the pun) but more than acceptable.

Kai of course is the parent company of Kershaw, Zero Tolerance, Shun Cutlery, and Kai has several lines of kitchen cutlery - the Luna and Inspire are the cheap ones...

How ridiculously cheap? At Amazon now it's under $8. I paid slightly more than that earlier for this one.

Blade -

mirror polish, hammered (tsuchi) finish looks attractive. Knife is light as the handle is plastic/resin with light gray soft-grip inserts. 3.75oz and the balance point is perfect for pinch grip at the blade, and suitable for the finger tip grip.

The sheath is really useful - but is pretty tight and has put those very fine scratches on the blade.

Listing says it's sharpened to 16deg per side.... but I seriously doubt that - as I did my usual sharpening/re-profiling on the Work Sharp Bench Grinder attachment at 10 deg to knock off the hard shoulder at the bevel - then sharpen at 15 deg - only 1 deg difference easily within my margin of error in keeping horizontal - the original edge bevel was substantially/noticeably more obtuse - had to grind quite extensively with X65 (200 grit) coarse belt to get the new convex bevel to reach the actual edge...... The bevel was also asymmetrical - so much for Kai of Seki City famous for blade/sword makers - this knife is made in China!

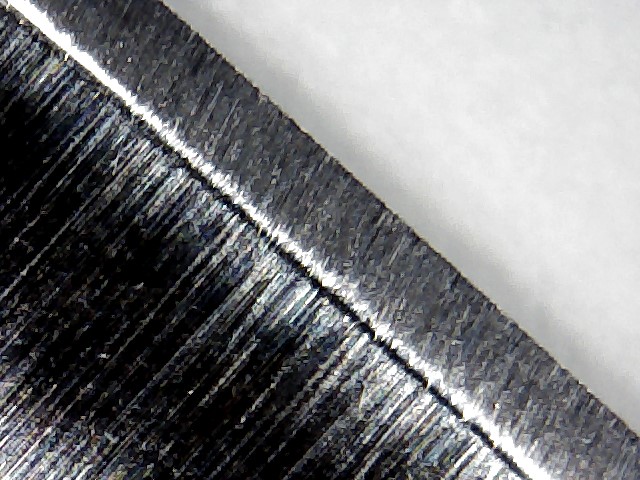

USB microscope pictures of edge about 2.5" from tip:

Logo side (notice how extensive the bevel is) -

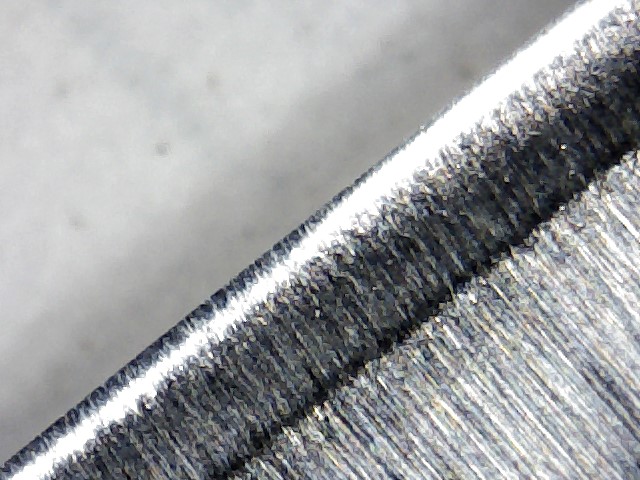

other side:

The knife was reasonably sharp out of the box - but now it's woo-hoo! DIN1.4116 is pretty fine grained and can be sharpened really well, lots of high quality (Western) kitchen knives used to be made with this, this steel makes the knife very durable and able to stand up to mishaps and dare I say it unintentional/uninformed abuse.

Size -

Santoku is a handy size for general purpose kitchen usage. For the price - one couldn't even buy most 3" paring knives....

I highly recommend watching this video (nearly 14mins) all the way through - there is a wealth of information about knife handling, grip, handles and choice of steels/hardness.

In particular about steels used in knives - it is NOT just a case of the harder the better - it is not always about edge retention, but suitability of the food being prepared - it is a serious error to use a exotic/high tech powdered steel at 62+HRC to chop through bones....

watch the above video at 9:49 (link to that starting point)

EDIT to ADD -

This was so cheap I simply had to buy another.

and boy was I lucky!

This second one was even better....

The blade face is even more obviously convex - it even looks prettier. Since I was aware the sheath can scratch the blade - haven't used it yet.

That's why the blade is still pristine.

It should be noted these are thin - 1.66mm at the spine (but the hammered finish might prevent a good measurement - so the thickness at the face right after the hammered part is 1.48mm, and right behind the edge is about 0.82mm. A good thickness, thick enough for heft and stiffness, yet thin enough to behave/cut like a Japanese knife. Light at 3.74oz.

USB microscope pic of edge about 2.5" from tip -

logo side:

back side -

Do my usual sharpening with Work Sharp Bench Grinder - first at 10deg just to remove the hard shoulder at the bevel - and was shocked to find that simply blended with the existing bevel - WoW! that is acute! then finished off with 15deg.

USB microscope of 10 then 15 deg convex sharpening -

logo side -

back side -

They almost look the same as the original edge - but I know I worked on the edge.

The reason why these look the same as the original, is simply because I did the cardinal sin of not reaching the edge, and was only grinding the shoulder of the old/original bevel - I am really embarrassed to have made such a basic fundamental error (please see the corrected pics in EDIT to ADD 4 below).

to have made such a basic fundamental error (please see the corrected pics in EDIT to ADD 4 below).

So what to do with the first knife?

Put a MicroForge edge on it to compare back-to-back.

USB microscope -

first Luna Santoku MicroForged - logo side

back side -

My thoughts - these Kai Luna Santokus (other than being cheap) have DIN1.4116 stainless steel @ 56-57HRC - may seem laughable compared to the 60+HRC stuff I have.

BUT there is a HUGE advantage of this so called softer steel. It might not hold an edge as long as 60HRC - but it is less brittle (too many people complain about their premium knives chipping) durable and can stand up to inadvertent/unintended abuse.

DIN1.4116 was a "premium" steel for top German chef's knives - they have an entirely different intended purpose of being able to do almost everything in the kitchen.

Of course Gyutos and Japanese fusion knives have "superior" steels - for edge holding and ability to take and hold more acute angles - but they are much more brittle - hence the too many complaints of chipping - because most westerners use a Gyuto like a regular western chef's knife!!! and chopping through bones? a NO-NO for Gyutos but quite common for regular western chef's knives. People were outraged when some western chef's knives were dropped in hardness to 55-56HRC - just because of possible abuse in the kitchen - think about it.

So in this cheapo Kai Luna Santoku - I have a knife - that's as tough as an old school western chef's knife (meant to be able to do everything) - this Santoku has a convex grind and acute edge - so behaves more like a sharper Japanese knife.

By putting a real convex edge on it - gives it a slight advantage of more durable edge - and to crown it with Work Sharp's MicroForge - gives it an edge that lasts longer.....

My story, my take - for less than $8, I have a knife that is functionally superior (for my home use) to most of my more exotic knives with high HRC... I may have to come back and take it all back - but I don't think that'll happen....

EDIT to ADD 2 -

I thought under $8 was already ridiculous -

well... they are down to under $7 now - get more than one.....

EDIT to ADD 3 -

When used back-to-back for my type of kitchen cutting, the MicroForged version despite being not quite as nice/good as the newer 10 then 15 deg sharpened knife - out cuts it and feels really aggressive in slicing - I think after a few more days (just to be sure) - I am likely to put the MicroForge on this newer one too. I'll probably do it in a new post with photos of the process. NOTE: this is flawed/incorrect as my original 10-15deg sharpening didn't even reach the edge - I've discovered and corrected this, see EDIT to ADD 4 below.

EDIT to ADD 4 -

The USB microscope pics above of my 10 then 15 deg sharpening - embarrassingly are completely misleading - as it didn't even reach the edge - I had only ground the shoulder of the original edge bevel!

I noticed this when I went to do a refresh sharpen before putting on MicroForge, and wondered why I did not seem to be raising a burr. Ah! the penny finally dropped, and I had to really do some extensive grinding to reach anywhere near the edge - so again like the first, this nicer second one had an edge that was more obtuse than the advertised 16deg.

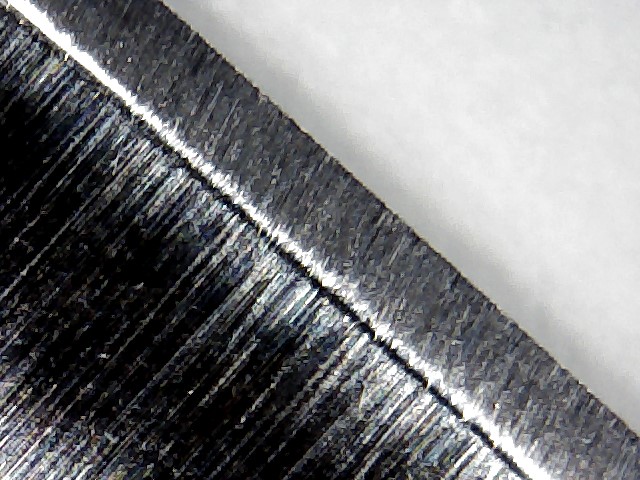

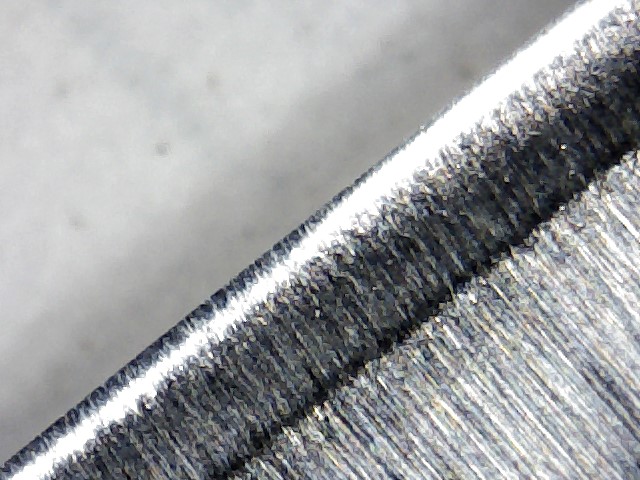

Below finally the correct USB microscope pics -

Logo side @ about 2.5" from tip (toward top left)-

other side (tip toward top right)

BUT now that I've put a proper edge on this second Santoku - all my back-to-back comparisons with the MicroForged first one, are now all invalid - so I'll have to do the comparisons again to see if I am going to put the MicroForge on this second (properly) sharpened one.

Sorry for my very embarrassing mistake.

mistake.

EDIT to ADD 5 -

See Post #51 (link) to mitigate/minimize sheath scratching the blade.

--

Vincent

https://Flickr.com/UnknownVincent/albums

https://Youtube.com/user/vtVincent

https://Goo.gl/q91ZNw

http://UnknownVincent.Shutterfly.com

http://UnknownVT.Shutterfly.com

.

Kai Luna Santoku - their listing says it's 7 in - but my measurement 6.5 in.

Most listings just say high carbon stainless steel - but Kai's website says German DIN1.4116 with 56-57HRC - not sterling (ha-ha! it's steel, sorry could not resist the pun) but more than acceptable.

Kai of course is the parent company of Kershaw, Zero Tolerance, Shun Cutlery, and Kai has several lines of kitchen cutlery - the Luna and Inspire are the cheap ones...

How ridiculously cheap? At Amazon now it's under $8. I paid slightly more than that earlier for this one.

Blade -

mirror polish, hammered (tsuchi) finish looks attractive. Knife is light as the handle is plastic/resin with light gray soft-grip inserts. 3.75oz and the balance point is perfect for pinch grip at the blade, and suitable for the finger tip grip.

The sheath is really useful - but is pretty tight and has put those very fine scratches on the blade.

Listing says it's sharpened to 16deg per side.... but I seriously doubt that - as I did my usual sharpening/re-profiling on the Work Sharp Bench Grinder attachment at 10 deg to knock off the hard shoulder at the bevel - then sharpen at 15 deg - only 1 deg difference easily within my margin of error in keeping horizontal - the original edge bevel was substantially/noticeably more obtuse - had to grind quite extensively with X65 (200 grit) coarse belt to get the new convex bevel to reach the actual edge...... The bevel was also asymmetrical - so much for Kai of Seki City famous for blade/sword makers - this knife is made in China!

USB microscope pictures of edge about 2.5" from tip:

Logo side (notice how extensive the bevel is) -

other side:

The knife was reasonably sharp out of the box - but now it's woo-hoo! DIN1.4116 is pretty fine grained and can be sharpened really well, lots of high quality (Western) kitchen knives used to be made with this, this steel makes the knife very durable and able to stand up to mishaps and dare I say it unintentional/uninformed abuse.

Size -

Santoku is a handy size for general purpose kitchen usage. For the price - one couldn't even buy most 3" paring knives....

I highly recommend watching this video (nearly 14mins) all the way through - there is a wealth of information about knife handling, grip, handles and choice of steels/hardness.

watch the above video at 9:49 (link to that starting point)

EDIT to ADD -

This was so cheap I simply had to buy another.

and boy was I lucky!

This second one was even better....

The blade face is even more obviously convex - it even looks prettier. Since I was aware the sheath can scratch the blade - haven't used it yet.

That's why the blade is still pristine.

It should be noted these are thin - 1.66mm at the spine (but the hammered finish might prevent a good measurement - so the thickness at the face right after the hammered part is 1.48mm, and right behind the edge is about 0.82mm. A good thickness, thick enough for heft and stiffness, yet thin enough to behave/cut like a Japanese knife. Light at 3.74oz.

USB microscope pic of edge about 2.5" from tip -

logo side:

back side -

Do my usual sharpening with Work Sharp Bench Grinder - first at 10deg just to remove the hard shoulder at the bevel - and was shocked to find that simply blended with the existing bevel - WoW! that is acute! then finished off with 15deg.

USB microscope of 10 then 15 deg convex sharpening -

logo side -

back side -

They almost look the same as the original edge - but I know I worked on the edge.

The reason why these look the same as the original, is simply because I did the cardinal sin of not reaching the edge, and was only grinding the shoulder of the old/original bevel - I am really embarrassed

So what to do with the first knife?

Put a MicroForge edge on it to compare back-to-back.

USB microscope -

first Luna Santoku MicroForged - logo side

back side -

My thoughts - these Kai Luna Santokus (other than being cheap) have DIN1.4116 stainless steel @ 56-57HRC - may seem laughable compared to the 60+HRC stuff I have.

BUT there is a HUGE advantage of this so called softer steel. It might not hold an edge as long as 60HRC - but it is less brittle (too many people complain about their premium knives chipping) durable and can stand up to inadvertent/unintended abuse.

DIN1.4116 was a "premium" steel for top German chef's knives - they have an entirely different intended purpose of being able to do almost everything in the kitchen.

Of course Gyutos and Japanese fusion knives have "superior" steels - for edge holding and ability to take and hold more acute angles - but they are much more brittle - hence the too many complaints of chipping - because most westerners use a Gyuto like a regular western chef's knife!!! and chopping through bones? a NO-NO for Gyutos but quite common for regular western chef's knives. People were outraged when some western chef's knives were dropped in hardness to 55-56HRC - just because of possible abuse in the kitchen - think about it.

So in this cheapo Kai Luna Santoku - I have a knife - that's as tough as an old school western chef's knife (meant to be able to do everything) - this Santoku has a convex grind and acute edge - so behaves more like a sharper Japanese knife.

By putting a real convex edge on it - gives it a slight advantage of more durable edge - and to crown it with Work Sharp's MicroForge - gives it an edge that lasts longer.....

My story, my take - for less than $8, I have a knife that is functionally superior (for my home use) to most of my more exotic knives with high HRC... I may have to come back and take it all back - but I don't think that'll happen....

EDIT to ADD 2 -

I thought under $8 was already ridiculous -

well... they are down to under $7 now - get more than one.....

EDIT to ADD 3 -

When used back-to-back for my type of kitchen cutting, the MicroForged version despite being not quite as nice/good as the newer 10 then 15 deg sharpened knife - out cuts it and feels really aggressive in slicing - I think after a few more days (just to be sure) - I am likely to put the MicroForge on this newer one too. I'll probably do it in a new post with photos of the process. NOTE: this is flawed/incorrect as my original 10-15deg sharpening didn't even reach the edge - I've discovered and corrected this, see EDIT to ADD 4 below.

EDIT to ADD 4 -

The USB microscope pics above of my 10 then 15 deg sharpening - embarrassingly are completely misleading - as it didn't even reach the edge - I had only ground the shoulder of the original edge bevel!

I noticed this when I went to do a refresh sharpen before putting on MicroForge, and wondered why I did not seem to be raising a burr. Ah! the penny finally dropped, and I had to really do some extensive grinding to reach anywhere near the edge - so again like the first, this nicer second one had an edge that was more obtuse than the advertised 16deg.

Below finally the correct USB microscope pics -

Logo side @ about 2.5" from tip (toward top left)-

other side (tip toward top right)

BUT now that I've put a proper edge on this second Santoku - all my back-to-back comparisons with the MicroForged first one, are now all invalid - so I'll have to do the comparisons again to see if I am going to put the MicroForge on this second (properly) sharpened one.

Sorry for my very embarrassing

EDIT to ADD 5 -

See Post #51 (link) to mitigate/minimize sheath scratching the blade.

--

Vincent

https://Flickr.com/UnknownVincent/albums

https://Youtube.com/user/vtVincent

https://Goo.gl/q91ZNw

http://UnknownVincent.Shutterfly.com

http://UnknownVT.Shutterfly.com

.

Last edited: