- Joined

- Feb 27, 2013

- Messages

- 1,048

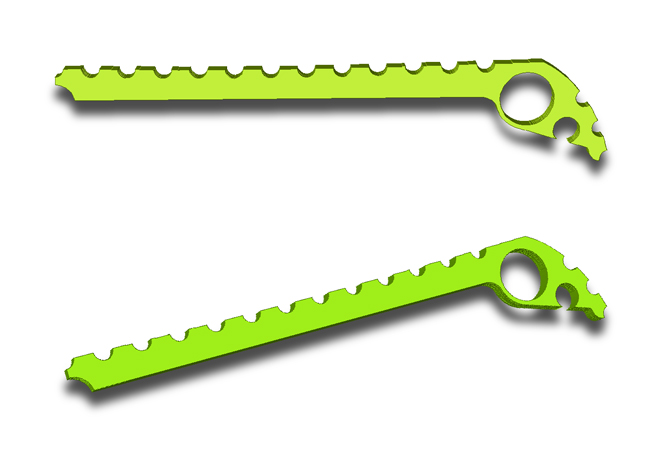

I've began working up what hopefully will result in a full back spacer for the CRK Large Sebenza and Insingo. There are a couple of issues right off the bat that make this more difficult than the back spacers for the Small Sebenza/Insingo... however I think these can be resolved with design tweaks.

Forum brother 91bravo has generously supplied one of his Large Insingos for me to disassemble and scan. The scans will allow me to be able to work the knife up in CAD and then CAM applications to arrive at machinable files.

The first hurdle I've encountered is the very tight tolerance of the Insingo blade to the lanyard hole. It turns out to be so close that my idea of machining my own stepped lanyard pin to solve the back spacer free rotation issue is not feasible. Even a small shouldered or stepped pin will have a strike issue. It also appears that the lanyard pin hole in the back spacer cannot even be full circumference for the same reason.

I'm still going to machine a carbon fiber lanyard pin however it will not be stepped or shouldered. If I can maintain a non-strike clearance with a straight lanyard pin it will require fixation into the back spacer with a dab of CA adhesive or epoxy.

We shall see... more as it happens...!

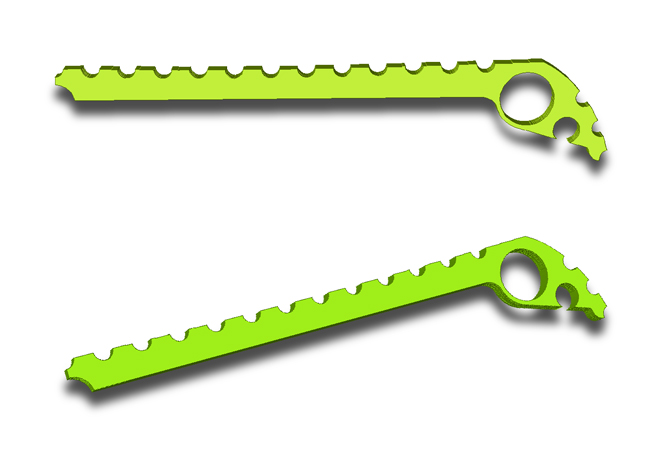

Forum brother 91bravo has generously supplied one of his Large Insingos for me to disassemble and scan. The scans will allow me to be able to work the knife up in CAD and then CAM applications to arrive at machinable files.

The first hurdle I've encountered is the very tight tolerance of the Insingo blade to the lanyard hole. It turns out to be so close that my idea of machining my own stepped lanyard pin to solve the back spacer free rotation issue is not feasible. Even a small shouldered or stepped pin will have a strike issue. It also appears that the lanyard pin hole in the back spacer cannot even be full circumference for the same reason.

I'm still going to machine a carbon fiber lanyard pin however it will not be stepped or shouldered. If I can maintain a non-strike clearance with a straight lanyard pin it will require fixation into the back spacer with a dab of CA adhesive or epoxy.

We shall see... more as it happens...!