Blues, thank you the photos help a lot. It looks like there is a lot of room for improvement and with rubber feet my contraption wouldn't need a holder.

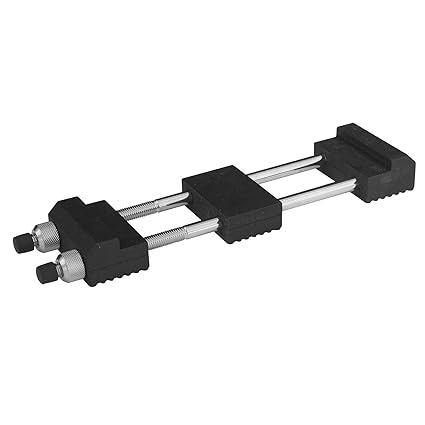

So I am at work today making polishing tape holders for EP, the fun of self employment, and having some ideas. I have no one else to bounce them off so here I am. What if I make stone holders for each size of stone? They would be fully machined aluminum blocks with all edges radiused and then hard anodized, with rubber feet. Think very roughly $35-$65 each. If I am making the stone holders too why not make it so "dovetails" on the stone ends snap into a spring loaded jaw on the stone holder, kind of like EP stones snap into the stone holder on their knife sharpeners? If the holders are heavy enough you could swaps stones with one hand in seconds. These stones will always be expensive, the knives you need them are too, so why not get a really nice stone holder that is designed exactly for your new stones? I would make sure the stones would still work in the stone holder Blues shows above, no reason not to. So, what do you think?

Keep in mind these stones are very long lasting so swarf is only the filing comming off the knife so they are pretty clean to use. More like plated diamonds than stones which make a lot more mess.

Oh, and I could make aluminum bodied leather strops that would snap into the stones holders.