- Joined

- Nov 15, 2005

- Messages

- 1,198

UPDATE - (7-27-19) - New Build and Results Finished on Page 2 Post #24!

Original Post:

--------------------------------------------------------------------

So... I recently rigged up a thermocouple in my forge in order to measure the temperature in my muffle pipe in an effort to aid in nailing some heat treat temperatures.

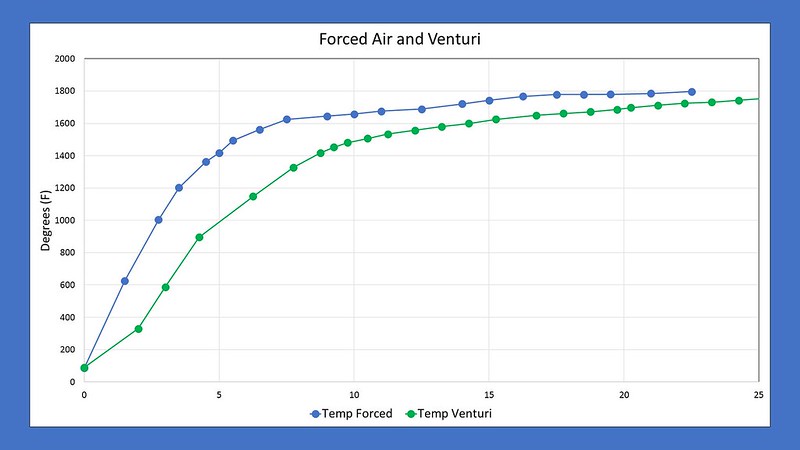

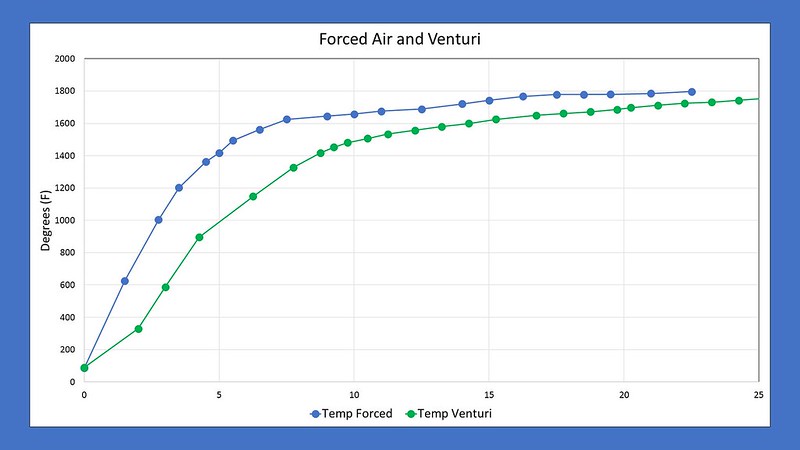

I quickly found that neither of my burners would perform much lower than 1800 F (results below). My forge is constructed from an air tank with 2 layers of kao-wool, satanite, and ITC-100.

Do yall have any ideas on how to modify my current forced air burner or suggestions on sizing to build a new burner that can get me in the 1500-1600 range?

Supporting Pictures and Video of my Setup:

Trying to show the tip (disregard the old wooden cart):

Cheers,

JK

Original Post:

--------------------------------------------------------------------

So... I recently rigged up a thermocouple in my forge in order to measure the temperature in my muffle pipe in an effort to aid in nailing some heat treat temperatures.

I quickly found that neither of my burners would perform much lower than 1800 F (results below). My forge is constructed from an air tank with 2 layers of kao-wool, satanite, and ITC-100.

Do yall have any ideas on how to modify my current forced air burner or suggestions on sizing to build a new burner that can get me in the 1500-1600 range?

Supporting Pictures and Video of my Setup:

Trying to show the tip (disregard the old wooden cart):

Cheers,

JK

Last edited: