-

The BladeForums.com 2024 Traditional Knife is ready to order! See this thread for details: https://www.bladeforums.com/threads/bladeforums-2024-traditional-knife.2003187/

Price is $300 ea (shipped within CONUS). If you live outside the US, I will contact you after your order for extra shipping charges.

Order here: https://www.bladeforums.com/help/2024-traditional/ - Order as many as you like, we have plenty.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

M390 in hard use

- Thread starter Skidoosh

- Start date

- Joined

- Feb 7, 2014

- Messages

- 11,432

CPM20cv and m390 (and CTS 204p) are virtually the same steel... given the same heat treatment, they should perform the same.

*edited to add:

*edited to add:

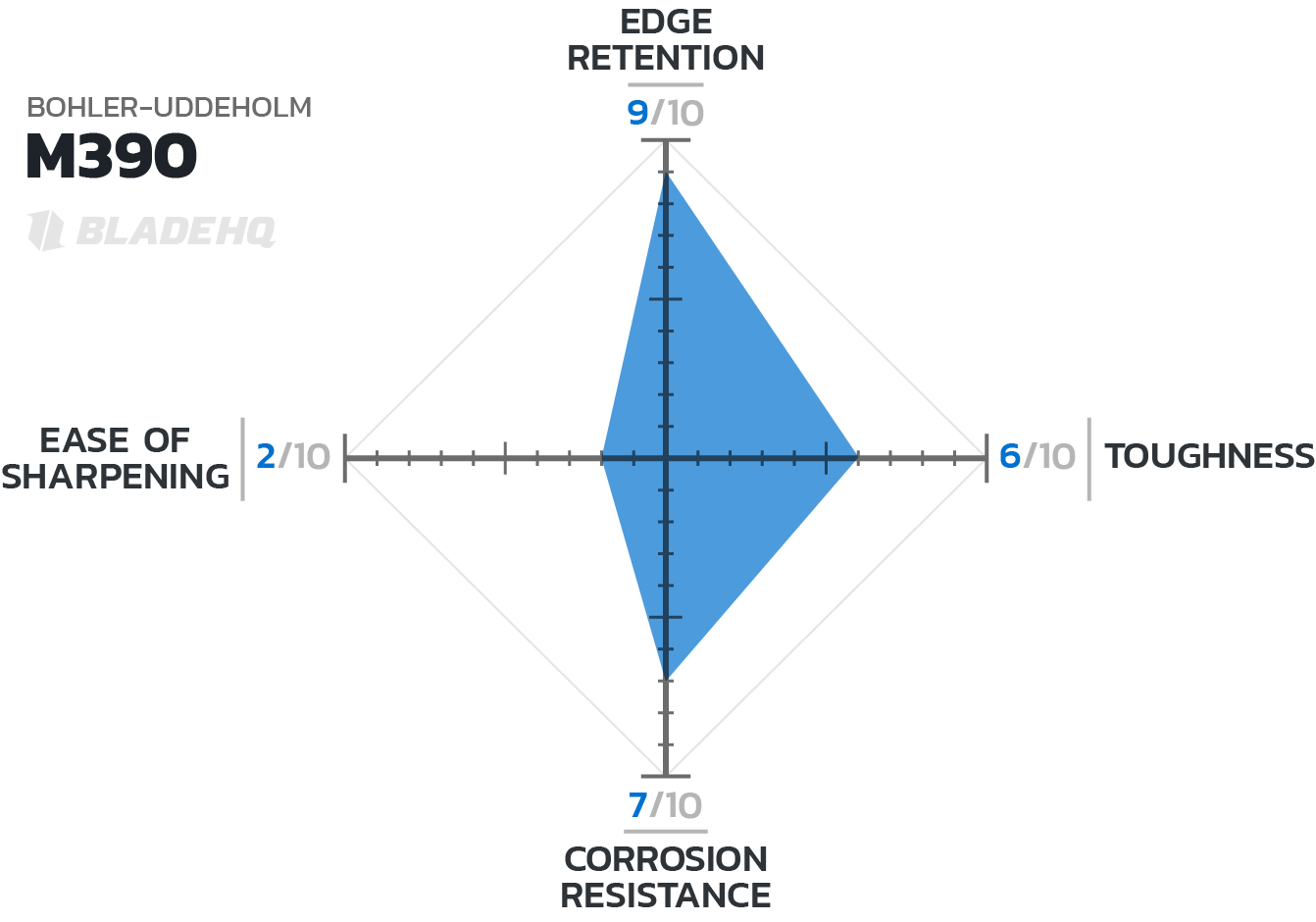

Bohler Uddeholm M390

Bohler M390 is widely revered as being the best all-around knife steel, which has led top companies to widely utilize it in higher end knives. M390 exhibits excellent edge retention, corrosion resistance, and high level toughness.

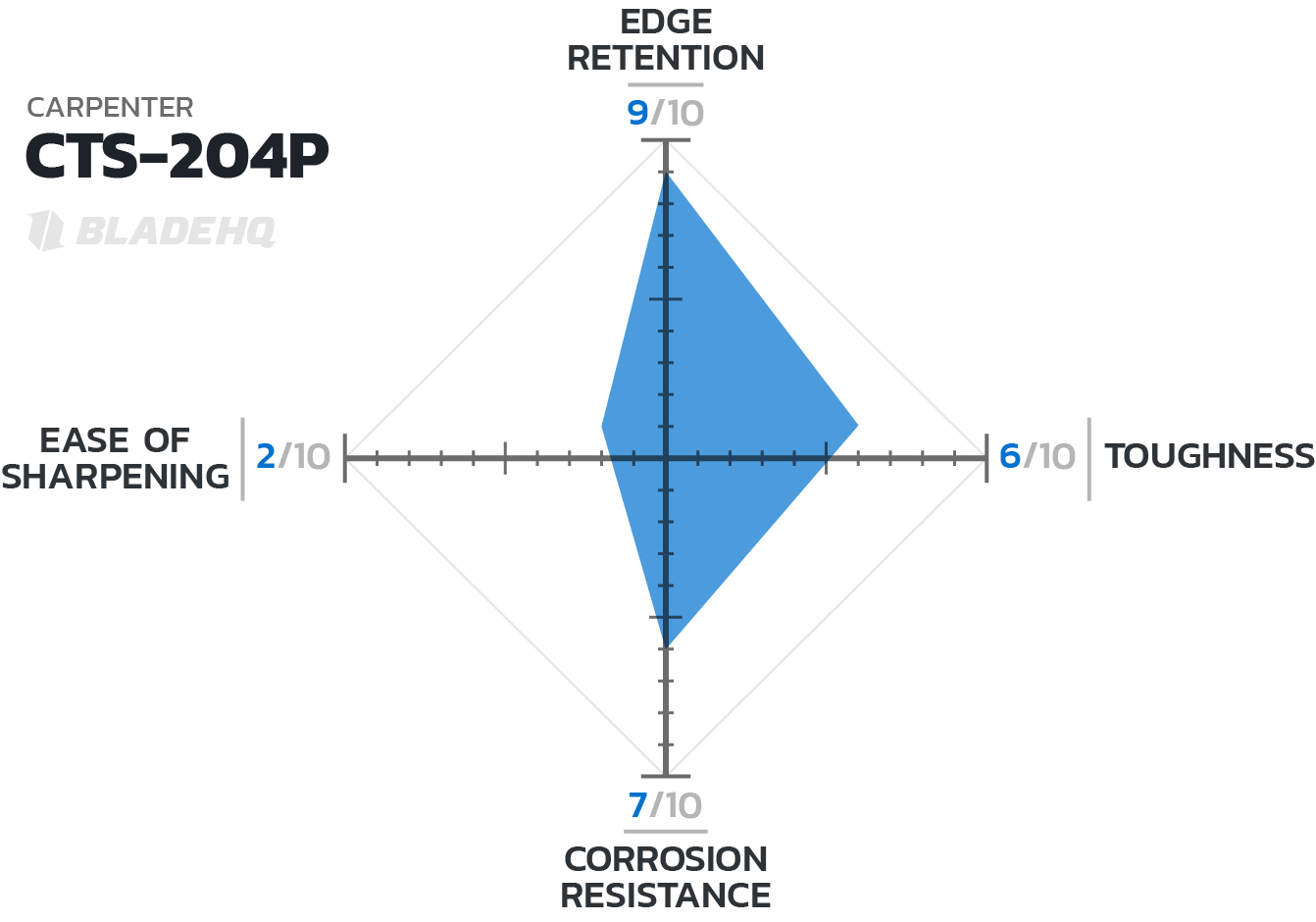

CTS-204P

Bohler M390, CTS-204P, and CPM-20CV are all essentially the same steel and sport a near identical composition. With significant amounts of Chromium, Molybdenum, Vanadium, and Tungsten, these steels are 100% ready for action. CTS-204P is made by the USA-based Carpenter Technology Corporation and CPM-20CV is manufactured by Crucible Industries.

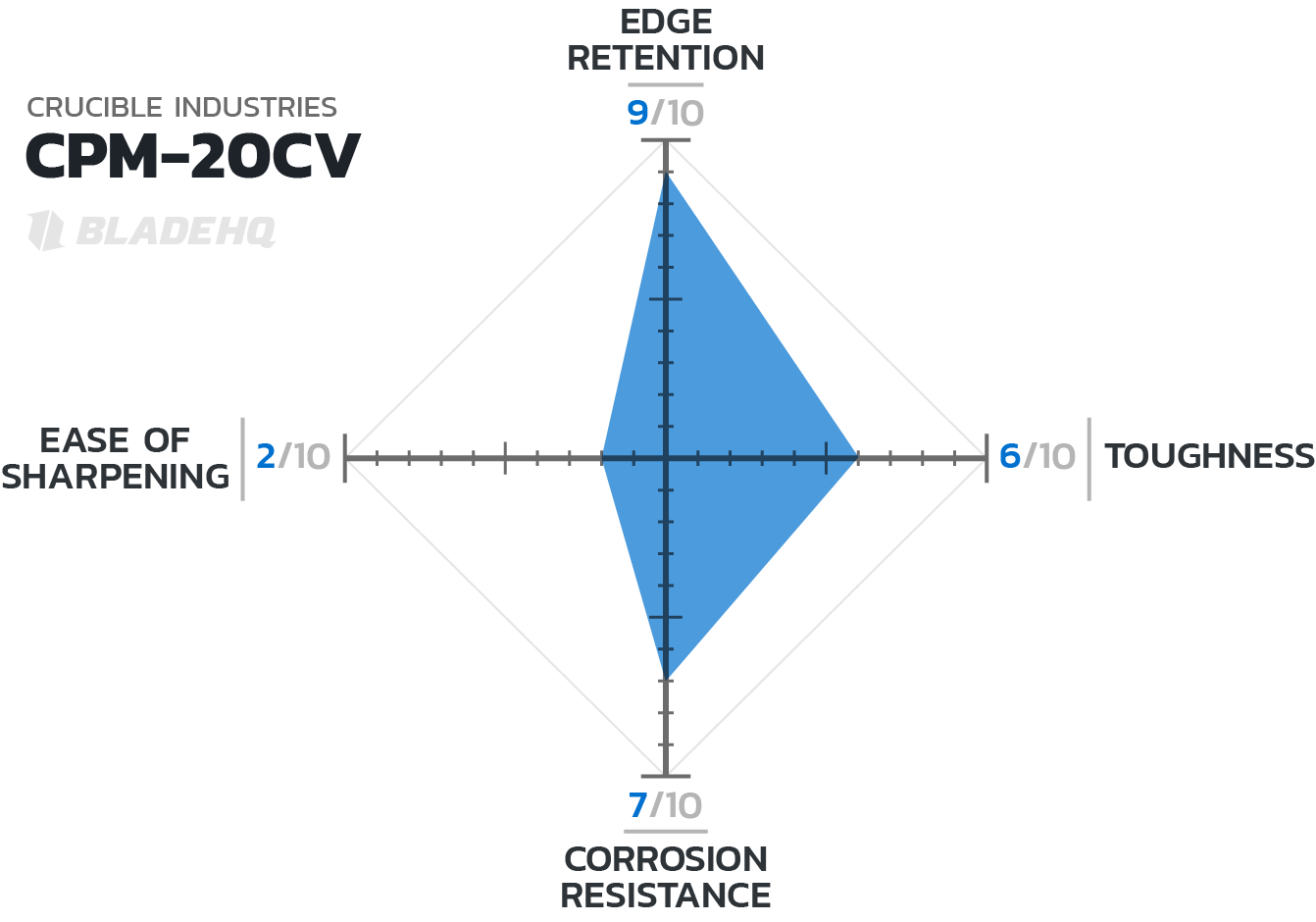

CPM-20CV

CPM-20CV can be found on my knives today and is made by the USA-based Crucible Industries. M390, 204P, and 20CV are all durable steels that sacrifice ease of sharpening.

Last edited:

- Joined

- Aug 17, 2014

- Messages

- 4,914

I have a Bradford Guardian 3 and 3.5, both in M390 and while I wouldn’t say I’ve really hard used/abused them I have battoned them both through 2’-3’ logs to split firewood and other such camp tasks. I also used the G3 to cut a reasonable amount of branches off of downed trees when I hiked a section of the PCT this summer.

Anyway, in those tasks they both performed great. No issues with edge stability or edge holding. I think Bradford has a great heat treat. And if you’re looking for more toughness they’ve done runs in Vanadis 4e, and 3V as well.

Anyway, in those tasks they both performed great. No issues with edge stability or edge holding. I think Bradford has a great heat treat. And if you’re looking for more toughness they’ve done runs in Vanadis 4e, and 3V as well.

- Joined

- Apr 6, 2017

- Messages

- 1,743

M390, 204p, and 20CV are the same composition made in different factories. None of them are particularly tough.

That's on the bladehq website. Click on the knife steels tab and it all pops up. It's not an exhaustive list, but pretty good none the less.hhmoore where did you find this info expressed in these blue diamond charts?

- Joined

- Nov 16, 2016

- Messages

- 6,760

M390, 204p, and 20CV are the same composition made in different factories. None of them are particularly tough.

^This

Toughness only matters if you use it beyond it's limit. So, are you going to hard use it only use it as a knife? IMO, the guardian 4 is probably too short to really add a ton of stress to it to the point it would break catastrophically. Toughness is often over-rated, IMO. If we were talking about a 7-12" chopper, I would have a very different outlook on the situation. But, just because it's a fixed blade doesn't mean you have to be rough on the blade.

I think you'll be fine, just don't try to pry off the trailer hitch too many times.

Last edited:

- Joined

- Mar 22, 2014

- Messages

- 5,355

Same steel basically, whatever built that impression of lower durability for you is how you sharpened it, the geometry, than the heat treatment. Steel is last.I'm looking a guardian in M390 and was wondering what people's experience is in fixed blades? I've got a 20cv knife that seems to work well but think of M390 as lower toughness. Change my mind.

That Bradford has plenty of meat on the blade to be durable enough for practical and reasonable use.

- Joined

- Aug 17, 2014

- Messages

- 4,914

Same steel basically, whatever built that impression of lower durability for you is how you sharpened it, the geometry, than the heat treatment. Steel is last.

That Bradford has plenty of meat on the blade to be durable enough for practical and reasonable use.

Perxactly.

Perxactly.- Joined

- Jul 24, 2010

- Messages

- 1,765

I use my EDC’s on hard plastics if need be. I’ve found 20cv from ZT too chippy. Been happy with S35VN from CRK lately, a breeze to touch up and the chips are minimal 59-60 RC. For wear resistance while retaining more toughness, I’ve liked M4 and Rex 45 from Spyderco.

- Joined

- Mar 22, 2014

- Messages

- 5,355

Factory edge?I use my EDC’s on hard plastics if need be. I’ve found 20cv from ZT too chippy. Been happy with S35VN from CRK lately, a breeze to touch up and the chips are minimal 59-60 RC. For wear resistance while retaining more toughness, I’ve liked M4 and Rex 45 from Spyderco.

Your edge?

How was it sharpened? Fixed angle system? Freehand? What angles? What stones? What finish?

- Joined

- Jul 24, 2010

- Messages

- 1,765

Factory edge?

Your edge?

How was it sharpened? Fixed angle system? Freehand? What angles? What stones? What finish?

The ZT was my freehand edge, DMT diamonds, Spyderco ceramics, leather strops with diamond paste, 30-35 inclusive. Was digging into some hard plastics. That’s been my only hard use experience with 20cv, m390, 204p. So it’s anecdotal for sure.

I had some Spyderco S90V that had a chippy factory edge. As soon as I put my edge on it the S90V performed great.

Just to be clear: Are you looking at a Bradford guardian in m390? Don't the bigger models of the Bradford Guardian all use CPM 3V? Only the smaller ones use m390, right?

If the above is correct, then what kind of 'hard use' do you have in mind?

I have the Bradford Guardian 3 in m390. It's a brilliant little cutter. Nice and thin blade profile, too. Small enough to edc, even. If by hard use you mean things like cutting a lot of cardboard or rope, I wouldn't hesitate to recommend the knife to you.

However, if by hard use you mean 'batonning' or some other kind of task that a knife isn't an appropriate tool for, then no knife will be right for you. And I'm having a hard time picturing how you would even attempt such a thing with a small knife like that.

If the above is correct, then what kind of 'hard use' do you have in mind?

I have the Bradford Guardian 3 in m390. It's a brilliant little cutter. Nice and thin blade profile, too. Small enough to edc, even. If by hard use you mean things like cutting a lot of cardboard or rope, I wouldn't hesitate to recommend the knife to you.

However, if by hard use you mean 'batonning' or some other kind of task that a knife isn't an appropriate tool for, then no knife will be right for you. And I'm having a hard time picturing how you would even attempt such a thing with a small knife like that.

- Joined

- Apr 6, 2017

- Messages

- 1,743

Actually, toughness (and strength) would matter if he's doing something that chips edges, like he alluded to above where he mentions that he cuts hard plastics with his EDC knives. That's the edge being pushed past its ultimate strength limit to the point of fracture. He could benefit from using a steel other than production M390 for that kind of task.^This

Toughness only matters if you use it beyond it's limit. So, are you going to hard use it only use it as a knife? IMO, the guardian 4 is probably too short to really add a ton of stress to it to the point it would break catastrophically. Toughness is often over-rated, IMO. If we were talking about a 7-12" chopper, I would have a very different outlook on the situation. But, just because it's a fixed blade doesn't mean you have to be rough on the blade.

I think you'll be fine, just don't try to pry off the trailer hitch too many times.

Edit: I mistakenly confused P2P's post as being from OP. In any case, toughness isn't only beneficial for large knives.

Last edited:

- Joined

- Mar 22, 2014

- Messages

- 5,355

Thanks for sharing, I think it's important to keep track of this stuff when evaluating steels. I've found in testing it can be HUGE especially when making judgement on what the steel is capable of.The ZT was my freehand edge, DMT diamonds, Spyderco ceramics, leather strops with diamond paste, 30-35 inclusive. Was digging into some hard plastics. That’s been my only hard use experience with 20cv, m390, 204p. So it’s anecdotal for sure.

I had some Spyderco S90V that had a chippy factory edge. As soon as I put my edge on it the S90V performed great.

Thanks

SVTFreak

Gold Member

- Joined

- Mar 8, 2011

- Messages

- 5,488

That's on the bladehq website. Click on the knife steels tab and it all pops up. It's not an exhaustive list, but pretty good none the less.

thank you!

Lots of good advice in this thread. The take home is don’t abuse it and m390 will be great steel.

- Joined

- Nov 16, 2016

- Messages

- 6,760

Actually, toughness (and strength) would matter if he's doing something that chips edges, like he alluded to above where he mentions that he cuts hard plastics with his EDC knives. That's the edge being pushed past its ultimate strength limit to the point of fracture. He could benefit from using a steel other than production M390 for that kind of task.

The OP has not made any mention of cutting hard plastics. P2P did mention hard plastics. I'm also surprised the one that was chipping was a ZT as they supposedly run their steels on the softer side (I think there was a chart out there somewhere). Of course, geometry plays a big role in there two, as does the thin edge angle.

I also found it interesting that S90V worked out okay, which is also not known for being a tough steel. But again, not the OP which is who I was directing my initial comment at. For doing what P2P does, I think the more durable S35vn was a good choice. Depending on how hard, I've read that serrated edges work nice on plastic. I don't cut enough hard plastic, outside of nylon ties, to have much experience on that. Anything too hard and I tend to go at it with a saw on my multi-tool or larger if needed. Depends on the situation of course.

- Joined

- Apr 6, 2017

- Messages

- 1,743

The OP has not made any mention of cutting hard plastics. P2P did mention hard plastics. I'm also surprised the one that was chipping was a ZT as they supposedly run their steels on the softer side (I think there was a chart out there somewhere). Of course, geometry plays a big role in there two, as does the thin edge angle.

I also found it interesting that S90V worked out okay, which is also not known for being a tough steel. But again, not the OP which is who I was directing my initial comment at. For doing what P2P does, I think the more durable S35vn was a good choice. Depending on how hard, I've read that serrated edges work nice on plastic. I don't cut enough hard plastic, outside of nylon ties, to have much experience on that. Anything too hard and I tend to go at it with a saw on my multi-tool or larger if needed. Depends on the situation of course.

Ahh, you're right, I mistakenly thought that was OP. In any case, I think the point still stands that an edge can benefit from tough steels depending on what and how you cut. In other words, the knife doesn't need to be big or a chopper to benefit from tough steel. I guess I'm not sure what OP cuts, but I've chipped enough M390 analog on supposedly tough folding knives to know it's not tough relatively speaking, and that seems to be supported by what Larrin has found with his own toughness testing on the steel.

I'm not surprised that ZT's steel chips. I've experienced that with their steel. I have a suspicion that they don't do a great heat treat in general.

- Joined

- Mar 10, 2010

- Messages

- 609

Heat treat, grind, and edge geometry on my G3 & G4 in M390 from Bradford are excellent. Both hold their cutting edge against natural materials longer than my thumb can withstand the gimping.

I like the high saber on the G4 and full flat on the G3.

I like the high saber on the G4 and full flat on the G3.