You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Upcoming Knives In A2;Better Than Carbon V ?

- Thread starter goldie

- Start date

- Joined

- Jun 24, 2015

- Messages

- 1,824

Maybe, maybe not. I'm going to get a few and see first hand.

bikerector

Knifemaker / Craftsman / Service Provider

- Joined

- Nov 16, 2016

- Messages

- 6,600

A2 is pretty tried and true outdoorsman steel, if the HT is good. Holds a good edge and is still pretty resilient to abuse. I suspect the Carbon V wins out in the toughness category but loses in the stain resistance and edge retention, but I'm not sure how much. It should be a great choice for cold steel's mid and large sized blades.

Mike Sastre

Custom Crafted Concealex Sheaths

- Joined

- Mar 23, 1999

- Messages

- 1,919

I much prefer Carbon V for the big Bowies and have a long history of using it. One of the thingx CS excels in is heat treat, so just about any of their carbon steels are done well. Still, it's hard to beat Carbon V.

goldie

Gold Member

- Joined

- Feb 18, 2000

- Messages

- 4,229

I would wonder if mar tempered A2 would have any advantages. I have a well used carbon v trailmaster that has performed very well.I cut through about 20 feet of thick rhodedendrums ,it really went through them quick and easy.Some thicker branches were 3-4" thick was no problem for that knife.

- Joined

- Mar 2, 2014

- Messages

- 2,524

Heat treat is everything,and Im sure CS will do good job on it as always,their ht is better than most companies at any price point!old carbon v was excellent, and A2 should perform even than carbon v.

- Joined

- Apr 11, 2019

- Messages

- 233

It should be better than Carbon V, if the heat treat is optimal. We'll see!

Mike Sastre

Custom Crafted Concealex Sheaths

- Joined

- Mar 23, 1999

- Messages

- 1,919

Heat treat is everything,and Im sure CS will do good job on it as always,their ht is better than most companies at any price point!old carbon v was excellent, and A2 should perform even than carbon v.

In my experience, both A-2 and O-1 are more prone to rust tha Carbon V. All carbon steels will rust if not cared for.

- Joined

- Mar 2, 2014

- Messages

- 2,524

Cold steel heat treat is one of best for factory made knife,i edc Kudu now,reground it and cuts like razor now

Cold Steel Knives

Moderator

- Joined

- Apr 16, 2013

- Messages

- 1,272

Can't wait to show everyone!

I don't think CS does there own heat treat, they have whoever is making the knives probably do the HT. As for A2 properly done one of my favorite carbon steels. I always thought that some where along the line also that Carbon V was a modified 0170-? or even a modified 52100. Could be wrong on that one though.

- Joined

- May 21, 2000

- Messages

- 6,172

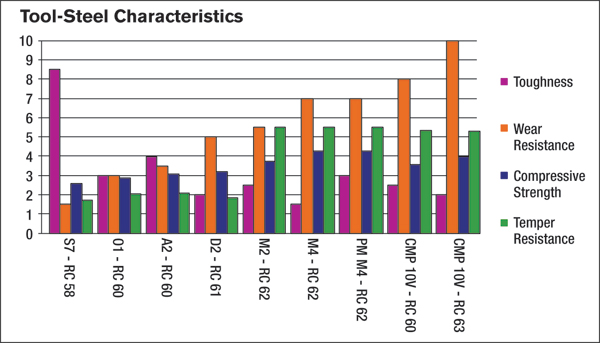

I imagine that A2 would have better edge retention than Carbon V.

A2 can be taken to a higher than average hardness while still being tough.

A2 can be taken to a higher than average hardness while still being tough.

Cobalt

Gold Member

- Joined

- Dec 23, 1998

- Messages

- 17,261

I imagine that A2 would have better edge retention than Carbon V.

A2 can be taken to a higher than average hardness while still being tough.

Better corrosion resistance than either O1 or 50100b as well. Done(HT) properly A2 is a great steel. Kinda a forgotten steel these days though. I am surprised they are going to A2 instead of 3V which they are already using on many of their fixed blades.

Better corrosion resistance than either O1 or 50100b as well. Done(HT) properly A2 is a great steel. Kinda a forgotten steel these days though. I am surprised they are going to A2 instead of 3V which they are already using on many of their fixed blades.

Everything I have seen, A2 is tougher, has more wear resistance, and more corrosion resistance than O1. I think O1 and 50100b(CarbonV) are pretty close in overall performance, so A2 should be the better all around steel than either.

Agreed, A2 should offer better toughness, wear resistance, and corrosion resistance than O1 for a minor increase in price ($10 retail). 3V would probably be a significant increase in price, for an increase in wear resistance over A2.

Last edited: