I know it's an old theme and I also know there is a load of threads on this. Still ...

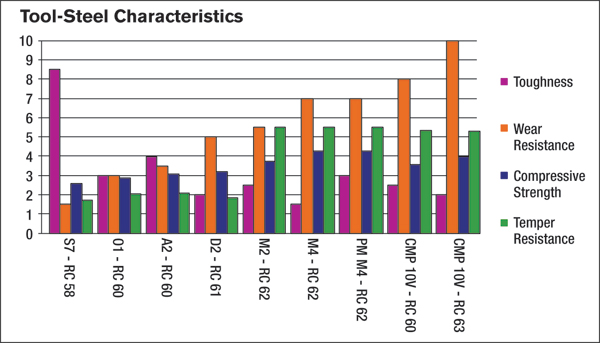

I am looking at the Landi LT Bushcrafter that I assume is made with L.T. Wright's assistance. I really want one just because I like the design a lot and hope it works as well as it looks. I can get it in O1 or in A2, but I can't decide. Personally, I am inclined to prefer a bit more rust resistance and edge holding, so this should answer my question. On the other hand, a lot of bushcraft people prefer O1 and they must have a reason.

I have no idea how O1 or A2 behave, I have no blades in those steels, I do have 1095, 1096 CroVan, D2, 440C, 154CM, M690, VG10, CPM S30V, CPM 3V. (I obviously don't need another knife but I do want the Landi because ... My fellow addicts will hopefully understand.)

I am looking at the Landi LT Bushcrafter that I assume is made with L.T. Wright's assistance. I really want one just because I like the design a lot and hope it works as well as it looks. I can get it in O1 or in A2, but I can't decide. Personally, I am inclined to prefer a bit more rust resistance and edge holding, so this should answer my question. On the other hand, a lot of bushcraft people prefer O1 and they must have a reason.

I have no idea how O1 or A2 behave, I have no blades in those steels, I do have 1095, 1096 CroVan, D2, 440C, 154CM, M690, VG10, CPM S30V, CPM 3V. (I obviously don't need another knife but I do want the Landi because ... My fellow addicts will hopefully understand.)