Warrior108

Platinum Member

- Joined

- Apr 24, 2012

- Messages

- 3,808

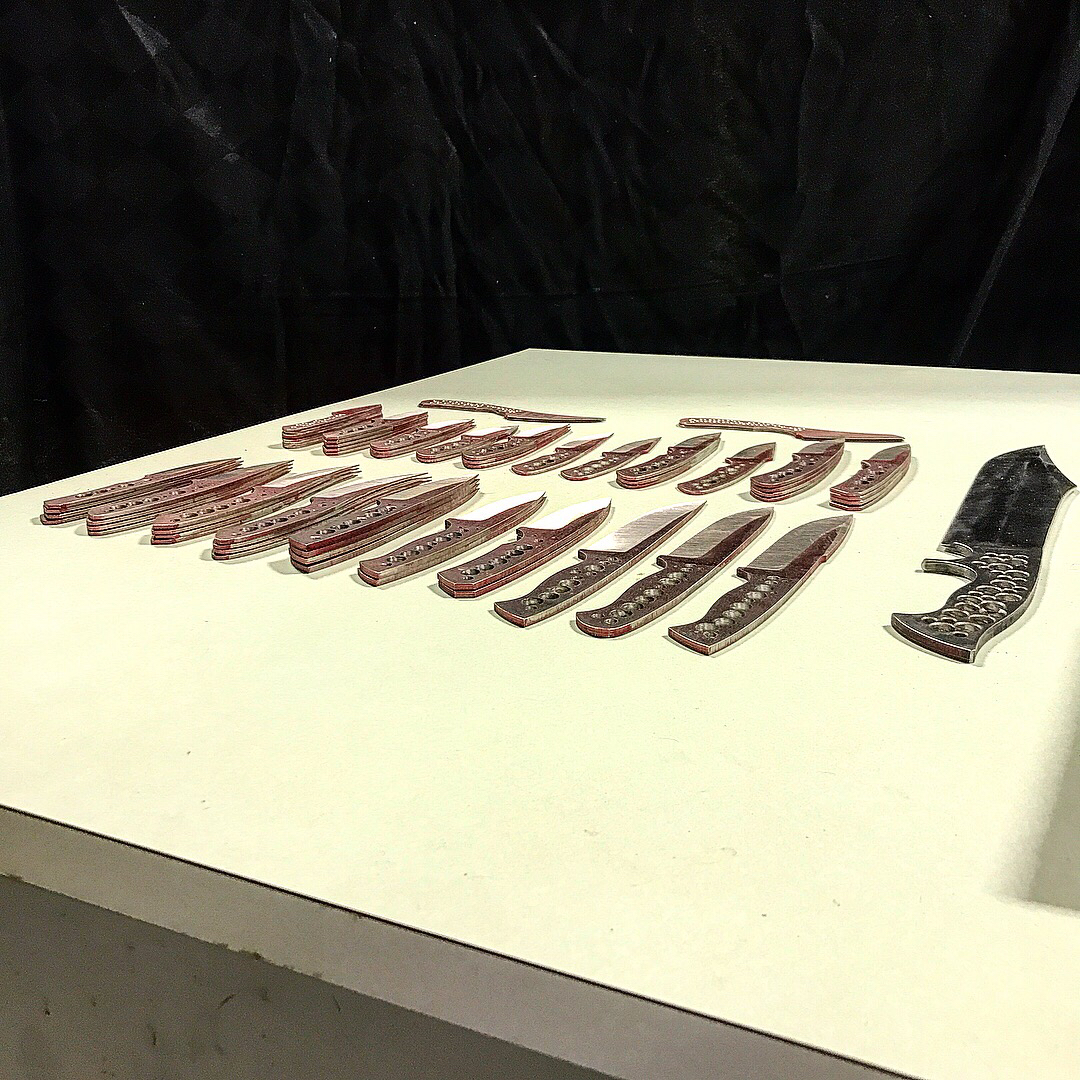

Hahaha .. I was thinking this also! Like, get Phillip to finish the shop and you concentrate on the knives >-)Knife pic update withdrawals over here... Just run some white caulk in those sheetrock joints and be done with it