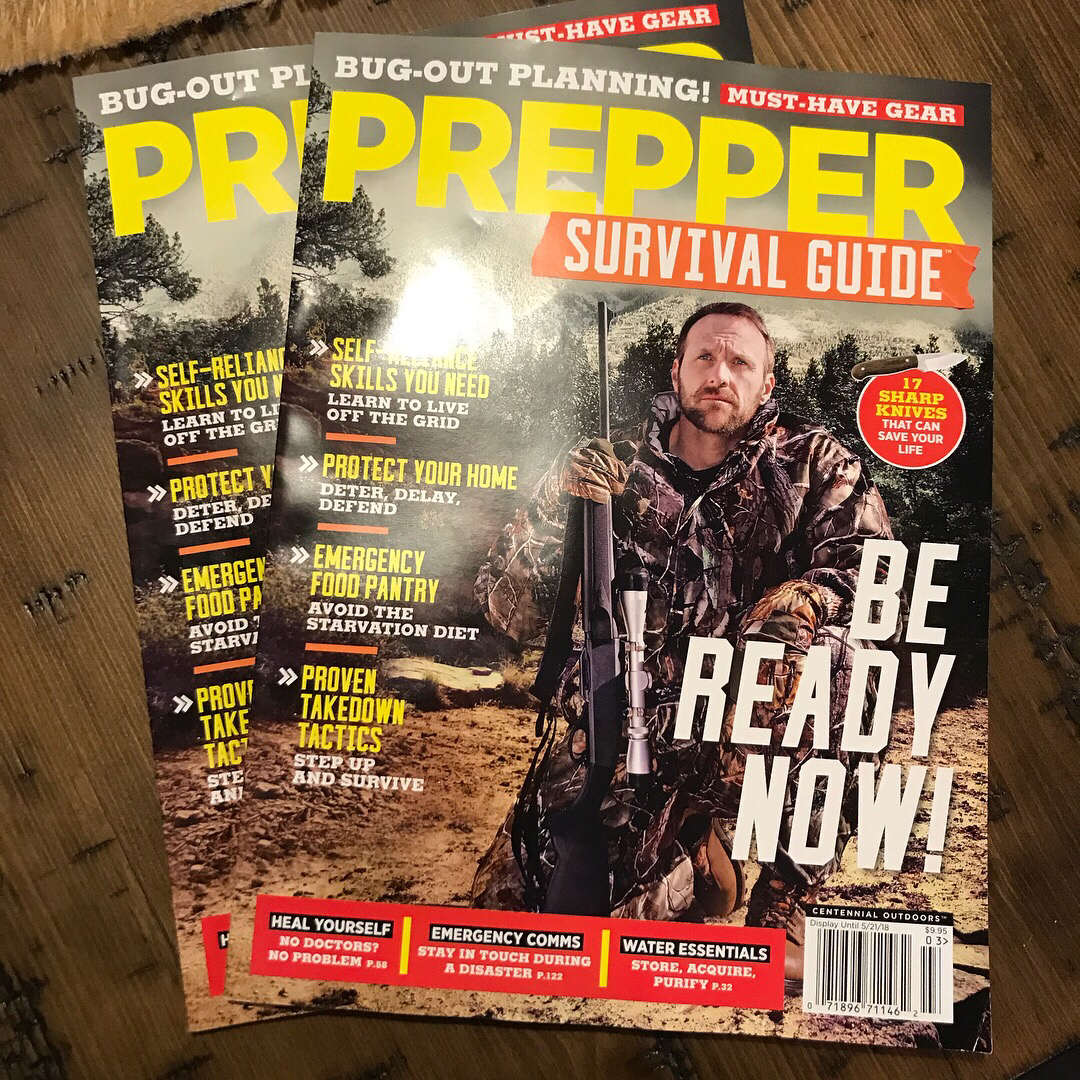

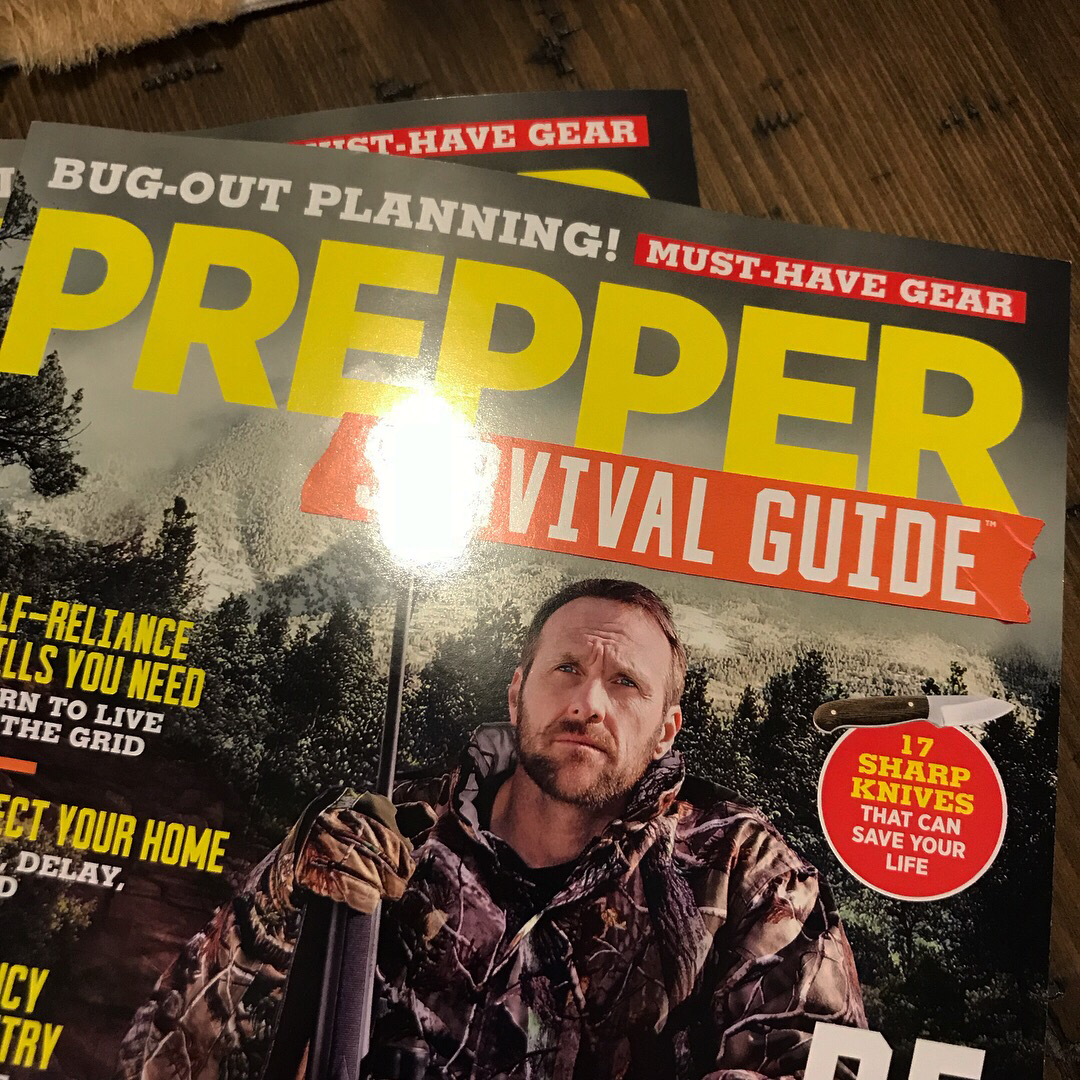

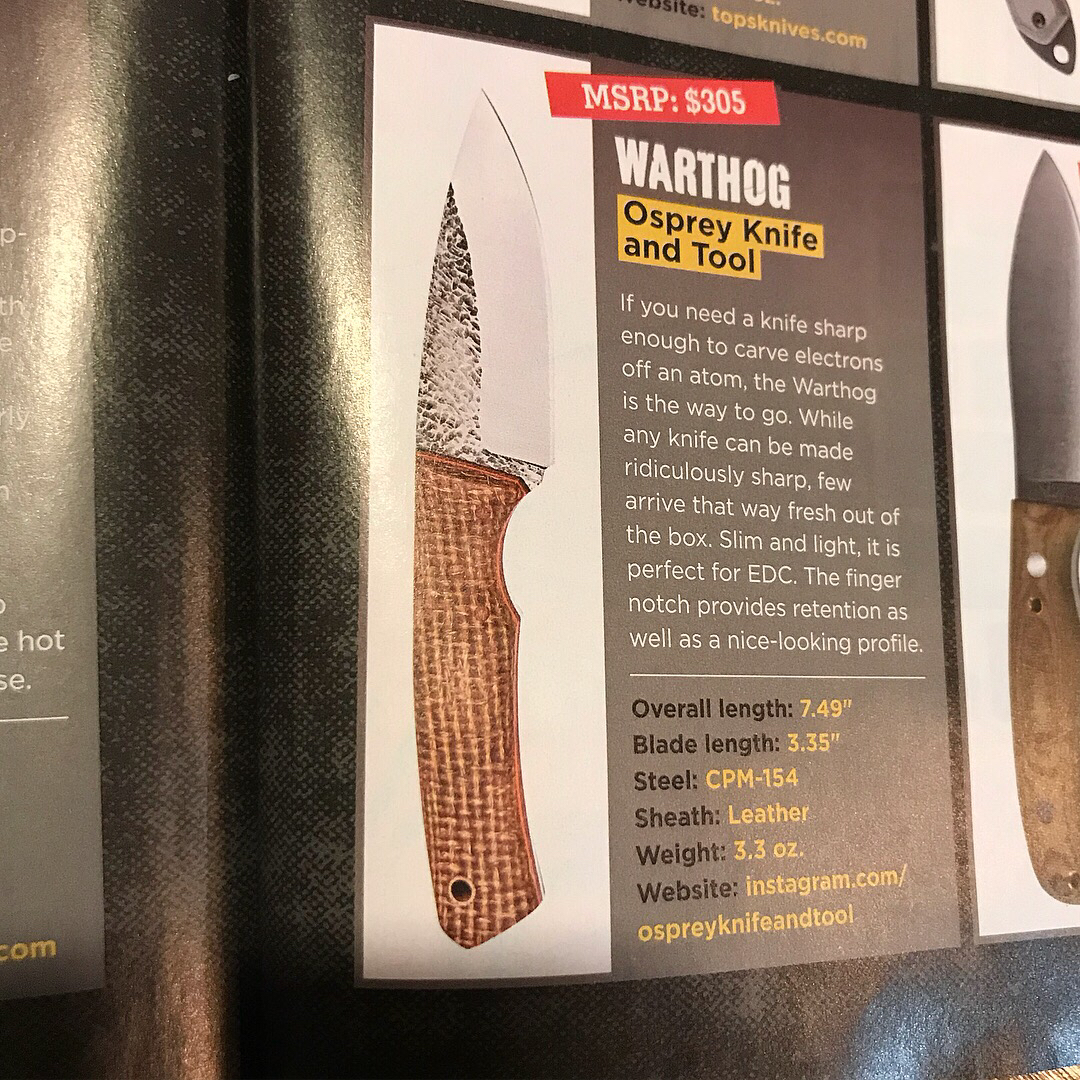

Osprey Knife & Tool

Moderator

- Joined

- Jun 4, 2014

- Messages

- 2,469

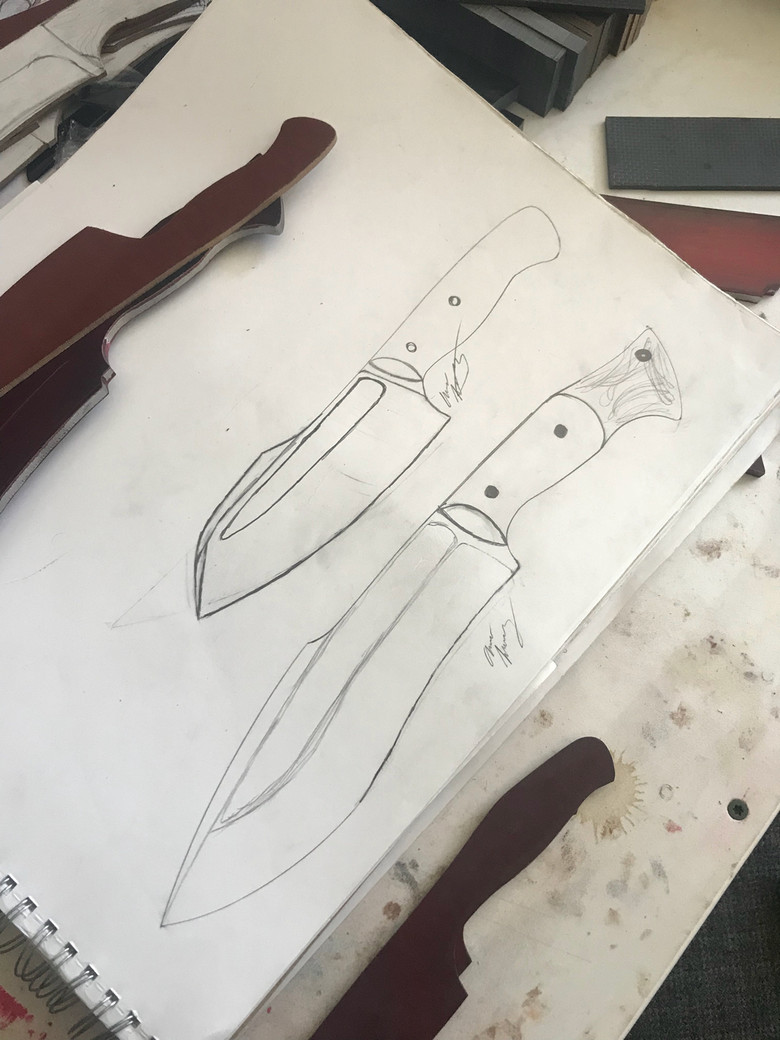

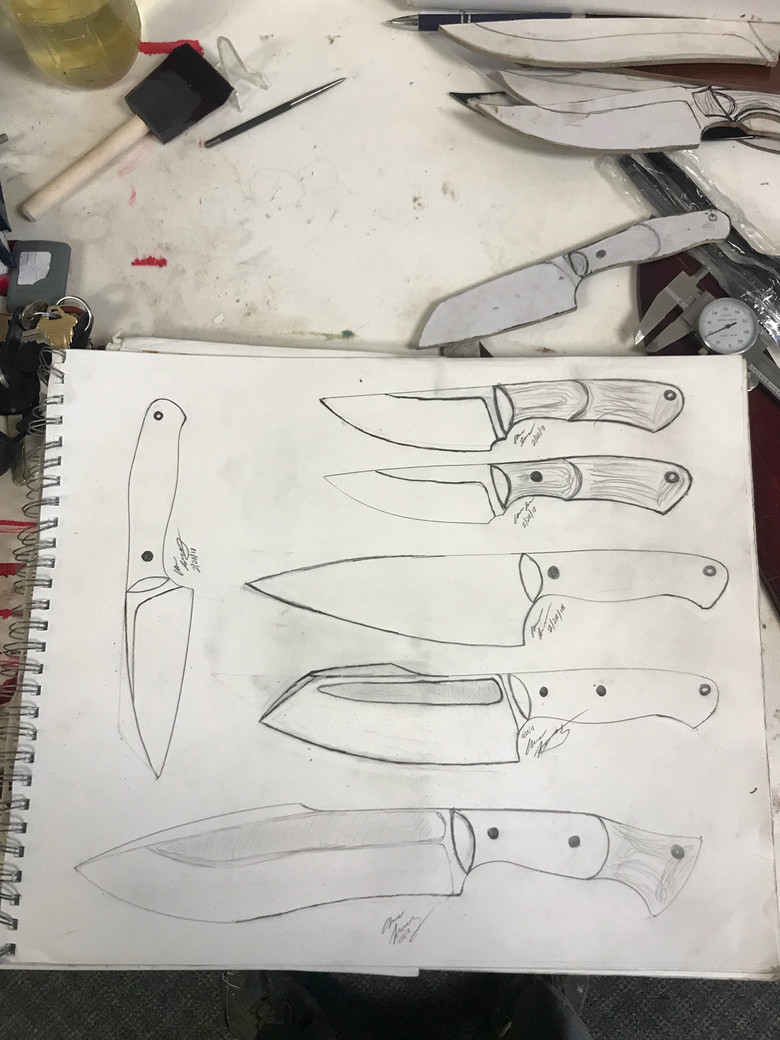

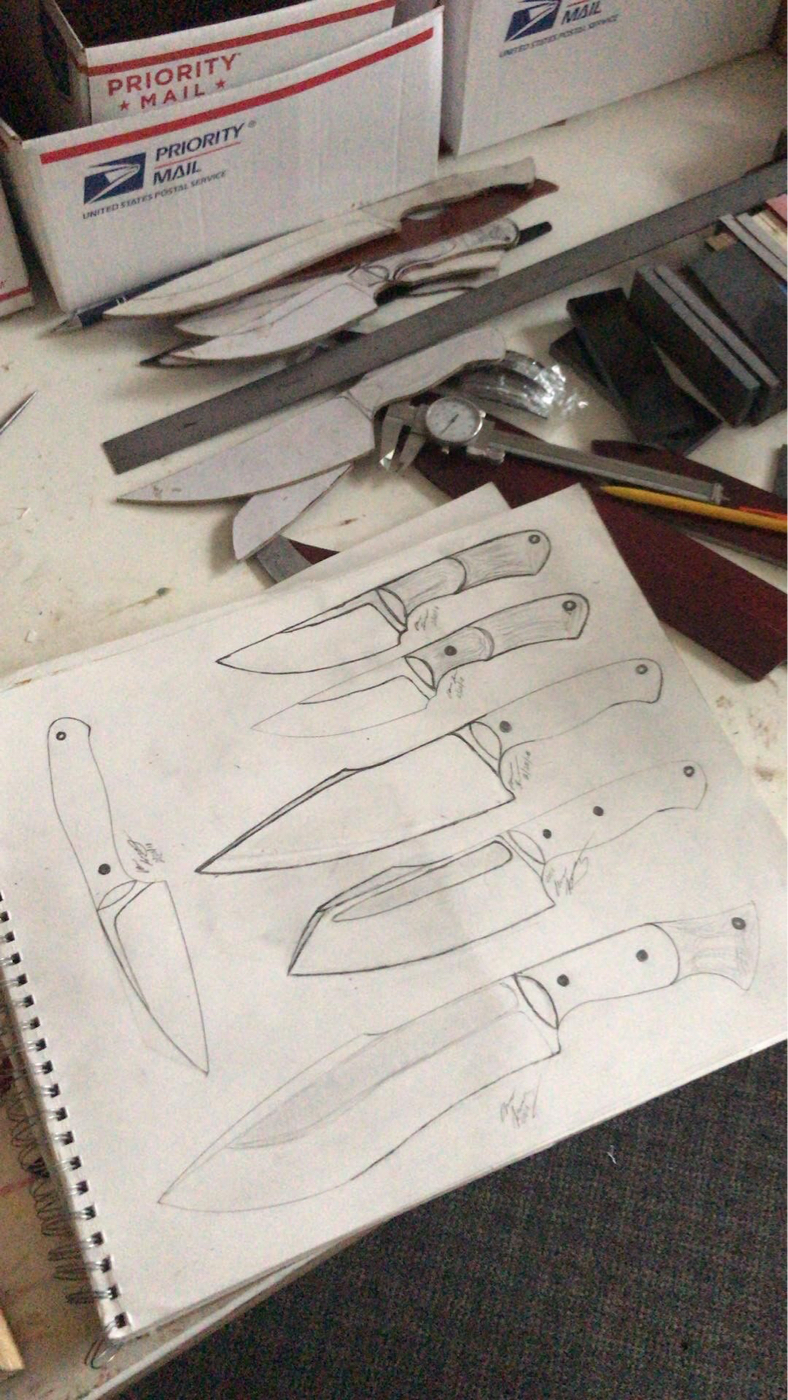

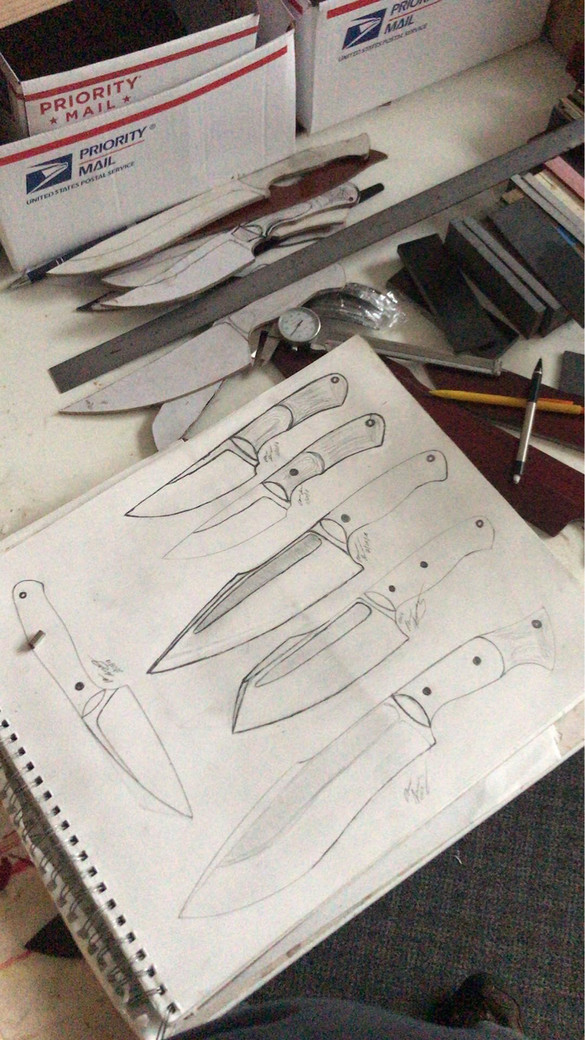

Its been awhile since I posted a preview of what I have been working on, Here is a little sneak peak of what I have been doing the last few days.

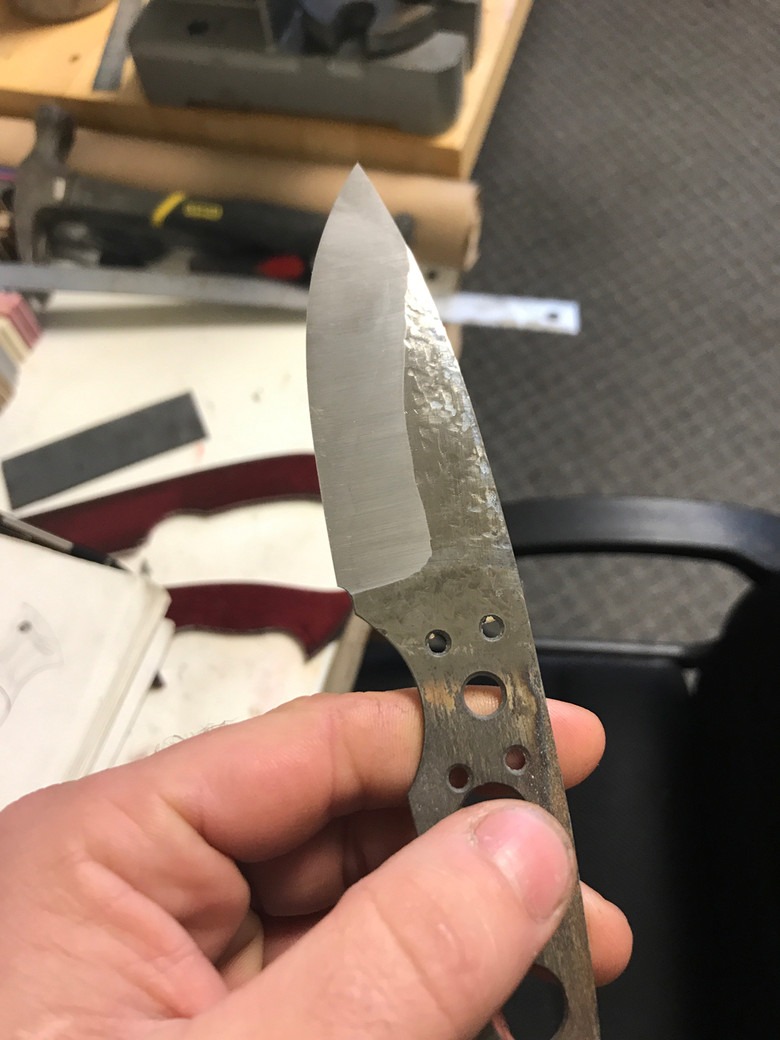

First video is a Bowie in W2 with a nice Hamon, it is polished to 800 grit.

I am not completley satisfied with the polish and etch so I will polish it somemore and etch again.

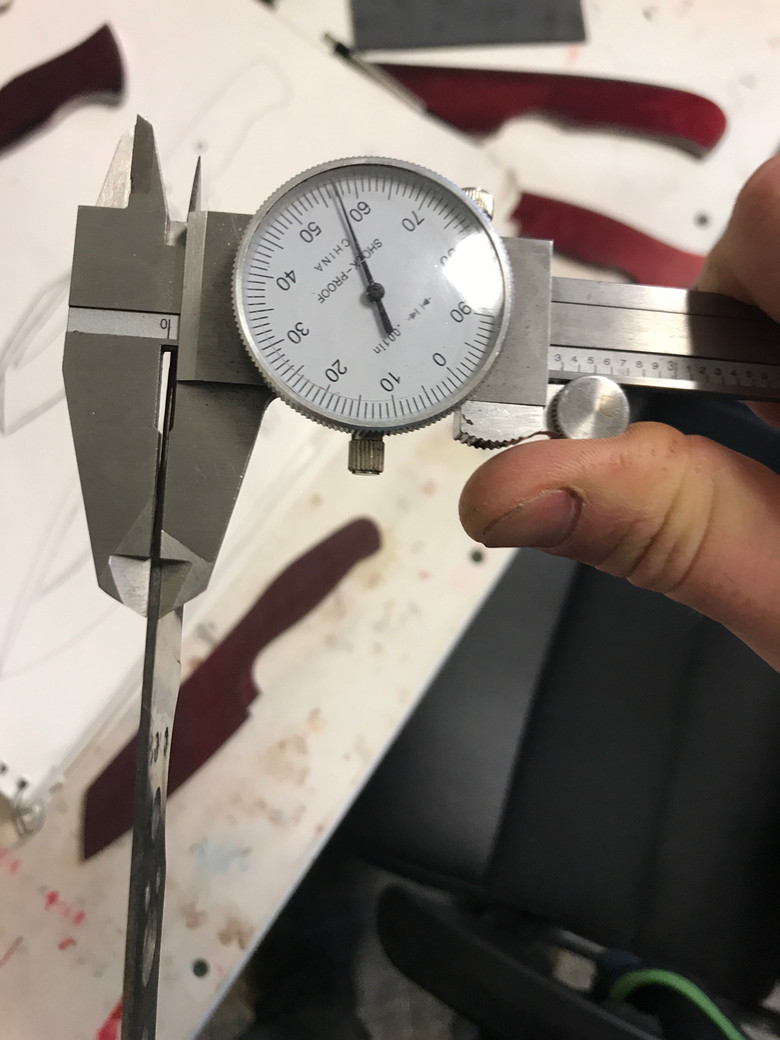

Second video is another Blade in W2 this one is a Raptor variant, but rather large (Bowie Large)]

This one is polished to 400 grit, and I did a test etch to see what it is I am working with.

Time to take it on up to a higher grit and do somemore etching!

More to come in the next few days!

First video is a Bowie in W2 with a nice Hamon, it is polished to 800 grit.

I am not completley satisfied with the polish and etch so I will polish it somemore and etch again.

Second video is another Blade in W2 this one is a Raptor variant, but rather large (Bowie Large)]

This one is polished to 400 grit, and I did a test etch to see what it is I am working with.

Time to take it on up to a higher grit and do somemore etching!

More to come in the next few days!