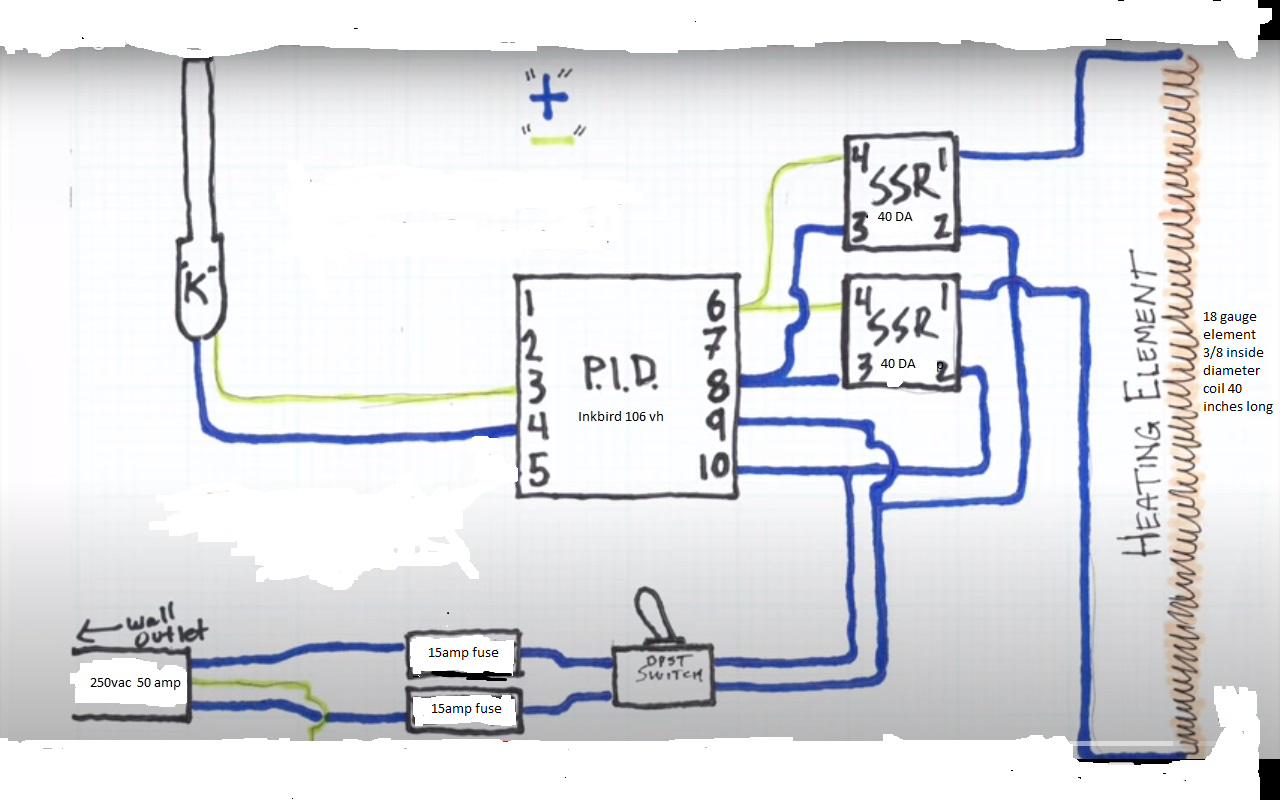

I need a little help figuring out what’s going wrong with my heat treat kiln. The plan I was following called for a 22 Gauge wire coil but I have burned out one and the other one stretched about 6 inches ( sagged out of groove where not pinned). So I made a new coil using 18 gauge coil. Now when i turn it on the pid runs through it’s set up ( 5 seconds ) then one of the 15 amp fuses blows. Not sure what's going on didn’t change anything other than coil. Here are the details of kiln. Please help me make this work.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Please help make heat treat oven work

- Thread starter 808blades

- Start date

Stacy E. Apelt - Bladesmith

ilmarinen - MODERATOR

Moderator

Knifemaker / Craftsman / Service Provider

- Joined

- Aug 20, 2004

- Messages

- 36,455

If you replaced a 22 gauge coil with the same length 18 gauge wire the amperage will go up a LOT. The resistance per inch for 18 gauge is .515 ohms per foot, compared to the 1.31 Ohms/ft that 22 gauge is.

JTknives

Blade Heat Treating www.jarodtodd.com

- Joined

- Jun 11, 2006

- Messages

- 8,630

22g wire is WAY to small and so is 18. Maybe if you where running 120v you might get away with 18g. You will see people using 16g and to me that’s even to small. 13g is about perfect for a heat treat oven and is what I use. But in my new oven I’m building I’m stepping up to 10g.

The diameter and length of your coil does not matter. What matters is the resistance and this is determined by the total length of kanthal A1 wire you used and it’s diameter. There is a bunch of math that you do to pick a element wire size. There is so thing called surface load and you have to fall with in the recommended bracket or you want t hot enough or you will over heat the wire and it will burn out. I wrote a spreadsheet calculator that does the match for me. This allows me to toss numbers around and see what works best for my needs. Here is an example of the numbers for my new oven. And if you get me your numbers I will toss them into this and post the results.

The diameter and length of your coil does not matter. What matters is the resistance and this is determined by the total length of kanthal A1 wire you used and it’s diameter. There is a bunch of math that you do to pick a element wire size. There is so thing called surface load and you have to fall with in the recommended bracket or you want t hot enough or you will over heat the wire and it will burn out. I wrote a spreadsheet calculator that does the match for me. This allows me to toss numbers around and see what works best for my needs. Here is an example of the numbers for my new oven. And if you get me your numbers I will toss them into this and post the results.

In your previous thread, you mentioned your inside chamber dimensions are 11"x4.5"x3.75", for a volume of approximately 0.1 cubic foot. That is a pretty small volume and you can easily run that on 110V. Commercial ovens typically have 4-8kW per cubic foot, an order of magnitude less than 15A at 240V for your chamber volume. For that size, 500-1,000W should be plenty.Thanks so much for your help. What numbers do you need to help me figure this all out?

While JT is correct in everything he says above, he does not address how to fit the coil into your furnace. The larger the wire gauge you use, the more wire is needed for the same resistance. You have some limitations and my guess is that you are running the coil back and forth in two channels per side that are sized to accommodate a 40" long coil with a diameter of just above 3/8". If you do not want to add new grooves, your options are pretty limited. If you can widen the grooves, you can fit a bigger coil, i.e., more wire length and thus a thicker gauge wire. You would have to use a 1/2" mandrel to wind your coil if you wanted to use 16 gauge Kanthal at around 40" stretched length to get to the power range mentioned above.

My recommendation would be to rewire for 110V and use an 18 gauge coil and see how long it lasts. When it burns out, you might want to build a bigger furnace anyway (I do), or add new grooves to accommodate a longer coil of thicker gauge. If you have a multimeter, measure the resistance of your current coil, or maybe let us know how many feet of wire you used to wind the coil. You might be able to just use that on 110V and it could last a good long while. If you want to make a new coil from 18 gauge Kanthal, I would recommend you start with 32-35ft for about 16-18 Ohms and 800-900W. You can go a bit shorter for more power (and reduced lifespan), but I would not recommend going much longer as that will prevent you from sufficiently stretching the coil.

JTknives

Blade Heat Treating www.jarodtodd.com

- Joined

- Jun 11, 2006

- Messages

- 8,630

I need your oven volume, total length of the grove that hold your element(s) and the power supply voltage and max amps your wanting to use. I can also run your current coil in my calculator. I need gauge and total wire length or at lease the resistance.

Thanks so much forIn your previous thread, you mentioned your inside chamber dimensions are 11"x4.5"x3.75", for a volume of approximately 0.1 cubic foot. That is a pretty small volume and you can easily run that on 110V. Commercial ovens typically have 4-8kW per cubic foot, an order of magnitude less than 15A at 240V for your chamber volume. For that size, 500-1,000W should be plenty.

While JT is correct in everything he says above, he does not address how to fit the coil into your furnace. The larger the wire gauge you use, the more wire is needed for the same resistance. You have some limitations and my guess is that you are running the coil back and forth in two channels per side that are sized to accommodate a 40" long coil with a diameter of just above 3/8". If you do not want to add new grooves, your options are pretty limited. If you can widen the grooves, you can fit a bigger coil, i.e., more wire length and thus a thicker gauge wire. You would have to use a 1/2" mandrel to wind your coil if you wanted to use 16 gauge Kanthal at around 40" stretched length to get to the power range mentioned above.

My recommendation would be to rewire for 110V and use an 18 gauge coil and see how long it lasts. When it burns out, you might want to build a bigger furnace anyway (I do), or add new grooves to accommodate a longer coil of thicker gauge. If you have a multimeter, measure the resistance of your current coil, or maybe let us know how many feet of wire you used to wind the coil. You might be able to just use that on 110V and it could last a good long while. If you want to make a new coil from 18 gauge Kanthal, I would recommend you start with 32-35ft for about 16-18 Ohms and 800-900W. You can go a bit shorter for more power (and reduced lifespan), but I would not recommend going much longer as that will prevent you from sufficiently stretching the coil.

In your previous thread, you mentioned your inside chamber dimensions are 11"x4.5"x3.75", for a volume of approximately 0.1 cubic foot. That is a pretty small volume and you can easily run that on 110V. Commercial ovens typically have 4-8kW per cubic foot, an order of magnitude less than 15A at 240V for your chamber volume. For that size, 500-1,000W should be plenty.

While JT is correct in everything he says above, he does not address how to fit the coil into your furnace. The larger the wire gauge you use, the more wire is needed for the same resistance. You have some limitations and my guess is that you are running the coil back and forth in two channels per side that are sized to accommodate a 40" long coil with a diameter of just above 3/8". If you do not want to add new grooves, your options are pretty limited. If you can widen the grooves, you can fit a bigger coil, i.e., more wire length and thus a thicker gauge wire. You would have to use a 1/2" mandrel to wind your coil if you wanted to use 16 gauge Kanthal at around 40" stretched length to get to the power range mentioned above.

My recommendation would be to rewire for 110V and use an 18 gauge coil and see how long it lasts. When it burns out, you might want to build a bigger furnace anyway (I do), or add new grooves to accommodate a longer coil of thicker gauge. If you have a multimeter, measure the resistance of your current coil, or maybe let us know how many feet of wire you used to wind the coil. You might be able to just use that on 110V and it could last a good long while. If you want to make a new coil from 18 gauge Kanthal, I would recommend you start with 32-35ft for about 16-18 Ohms and 800-900W. You can go a bit shorter for more power (and reduced lifespan), but I would not recommend going much longer as that will prevent you from sufficiently stretching the coil.

Thanks for the help and education! So if a rewire oven to 120 volt 30amp (circuit i use for welder) remove one of the SSR's and it's 15amp fuse and use the 18 gauge coil ( aprox 15' feet of wire for aprox 40" coil of 3/8 dia might that work? Will I blow the 15 amp fuse?

That coil is probably too short to last long. It will be around 15-16A current draw, close to 2kW at 120V. If you have left over 18 gauge that you want to use, you should start with 32-35ft to get a coil of reasonable wattage (800-900W). I think that will be fine for the small furnace you are building.Thanks so much for

Thanks for the help and education! So if a rewire oven to 120 volt 30amp (circuit i use for welder) remove one of the SSR's and it's 15amp fuse and use the 18 gauge coil ( aprox 15' feet of wire for aprox 40" coil of 3/8 dia might that work? Will I blow the 15 amp fuse?

If you have to buy new material, look at thicker gauges. Dan Comeau has a page about heat treat ovens with a basic coil calculator spreadsheet. Maybe that can help you to get a better idea what will work for you.

Here is some additional info regarding surface loads. The graphs below (from the Kanthal handbook) show maximum surface loads vs temperature for different element types. The yellow line is for a coil in grooves. For 18 gauge wire, you get roughly the following surface loads for different wattages:

- 800 W: 2.3 W/cm²

- 900 W: 3 W/cm²

- 1000 W: 3.6 W/cm²

- 1100 W: 4.4 W/cm²

It should be a 0.375" or 3/8" mandrel, not 3/16". There is a neat little jig you can build in minutes to wind the coil if you haven't built one already for the previous coil you made. The first video that came up is linked below. I used a similar jig and it worked very well. I would not recommend relying on the length of the wound coil, measure out the length of wire ahead of time and leave enough to double and twist the ends.I will be only using this for carbon steels for now. So if I use 18 gauge on a 3/16 mandrel with 28-30 ft of wire stretched out to aprox 40 inches with 120 volt 30amp circuit it should function well? Would i need to change my 15 amp fuse.

Again thanks so much for all your help!!! How many watts will this draw? How many ohms am I shooting for and finally how many amps will I draw. Thanks again.It should be a 0.375" or 3/8" mandrel, not 3/16". There is a neat little jig you can build in minutes to wind the coil if you haven't built one already for the previous coil you made. The first video that came up is linked below. I used a similar jig and it worked very well. I would not recommend relying on the length of the wound coil, measure out the length of wire ahead of time and leave enough to double and twist the ends.

At 28ft length, you will get 1,000W, 8.33A, 14.4Ω.Again thanks so much for all your help!!! How many watts will this draw? How many ohms am I shooting for and finally how many amps will I draw. Thanks again.

At 31ft length, you will get 900W, 7.5A, 16Ω.

At 35ft length, you will get 800W, 6.67A, 18Ω.

As a comparison point, my oven has about 90% more volume than yours and my element draws 1,350W give or take (the power changes slightly with temperature). It gets to carbon steel temperatures in about 30 minutes. I've always let it soak at least an extra thirty minutes after it gets to temperature. Unless you have a poor door seal or other insulation issues, your oven should heat more quickly than mine if you use an 800-1,000W coil.