- Joined

- Dec 25, 2019

- Messages

- 83

Hi guys

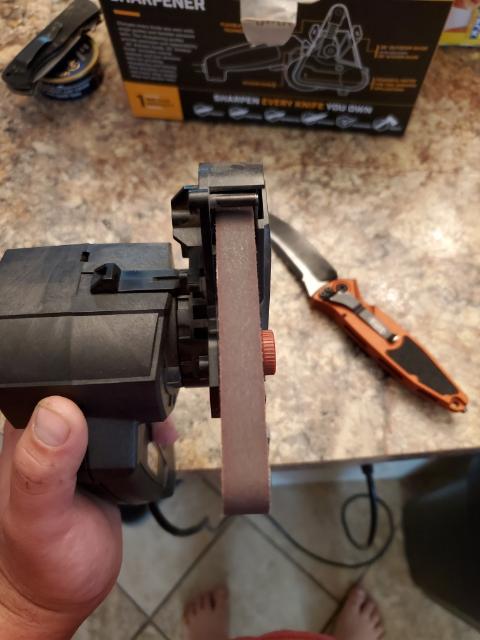

Looks for some advice here I have a spyderco UK pk tin s110v that I've gotten sharp (shaves hair but not effortlessly and not tiny thin hairs) first sharpened it 15 dps on worksharp and was unsatisfied so spent 2 hours with the kme putting a mirror on it with the sharpie trick making sure it removed all sharpie, I got a solid burr on both sides but it just won't get sharp like my other knives. Just did the exact same process with my manix in maxamet and that thing just looks at hairs and they jump off, have the ukpk in s30v and that again is scary sharp, this is my only s110v knife and I know they can be a pain but surely if I can sharpen maxamet I can sharpen anything?

Sorry for the waffle

Ryan

Looks for some advice here I have a spyderco UK pk tin s110v that I've gotten sharp (shaves hair but not effortlessly and not tiny thin hairs) first sharpened it 15 dps on worksharp and was unsatisfied so spent 2 hours with the kme putting a mirror on it with the sharpie trick making sure it removed all sharpie, I got a solid burr on both sides but it just won't get sharp like my other knives. Just did the exact same process with my manix in maxamet and that thing just looks at hairs and they jump off, have the ukpk in s30v and that again is scary sharp, this is my only s110v knife and I know they can be a pain but surely if I can sharpen maxamet I can sharpen anything?

Sorry for the waffle

Ryan