- Joined

- Jun 18, 2015

- Messages

- 518

I got get by the blade bug a couple of weeks ago and have put together a few entry-level blades in that time. Most are AUS-8 or 8Cr13MoV, but today I bought my first quality steel blade - a Spydie Sage 1 (S30V). And while the knife is quality, the factory edge wasn't the sharpest. So I'd like to do some sharpening and I'd love a recommendation for which technique or system I should use based on my specific situation. Here it is:

Most of my knives are EDC. 3" - 3.5" I plan to get a PM2 in the not too distant future (also S30V). I also own a couple of Zwilling Twin Four Star II kitchen knives (they don't seem to advertise what kind of steel they use, only that it's a high-carbon stainless). With the exception of the kitchen ones, my knives will usually see limited action around the house. So I can't imagine needing a full sharpening session more than once every 3 months for the time being. 6 months is probably more likely.

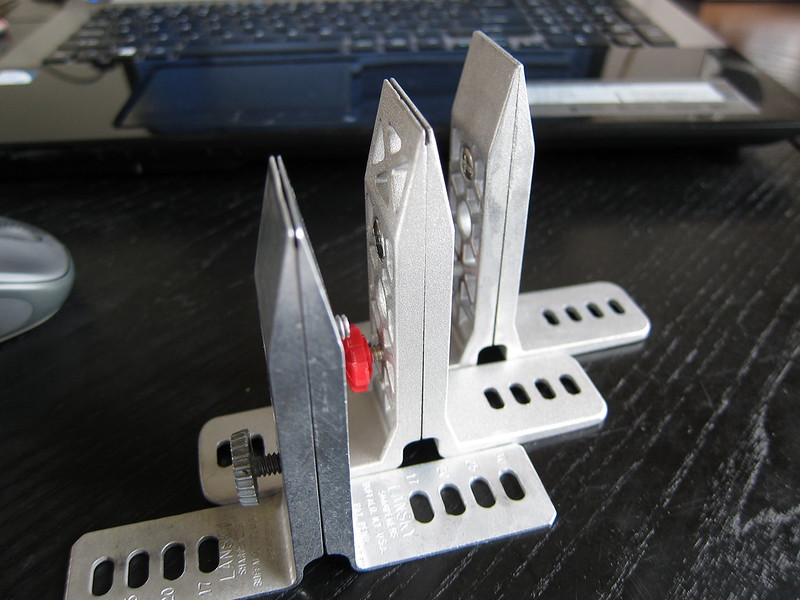

And while I love the idea of getting stones and doing this the traditional way, I have a feeling that even if I practice for a week, I'm going to have to relearn everything 3 - 6 months down the line. Am I right about this? Should I just get a guided system? And if so, is there a system that works better for Spydies (besides the Sharpmaker)?

Thanks for the help!

JW

Most of my knives are EDC. 3" - 3.5" I plan to get a PM2 in the not too distant future (also S30V). I also own a couple of Zwilling Twin Four Star II kitchen knives (they don't seem to advertise what kind of steel they use, only that it's a high-carbon stainless). With the exception of the kitchen ones, my knives will usually see limited action around the house. So I can't imagine needing a full sharpening session more than once every 3 months for the time being. 6 months is probably more likely.

And while I love the idea of getting stones and doing this the traditional way, I have a feeling that even if I practice for a week, I'm going to have to relearn everything 3 - 6 months down the line. Am I right about this? Should I just get a guided system? And if so, is there a system that works better for Spydies (besides the Sharpmaker)?

Thanks for the help!

JW