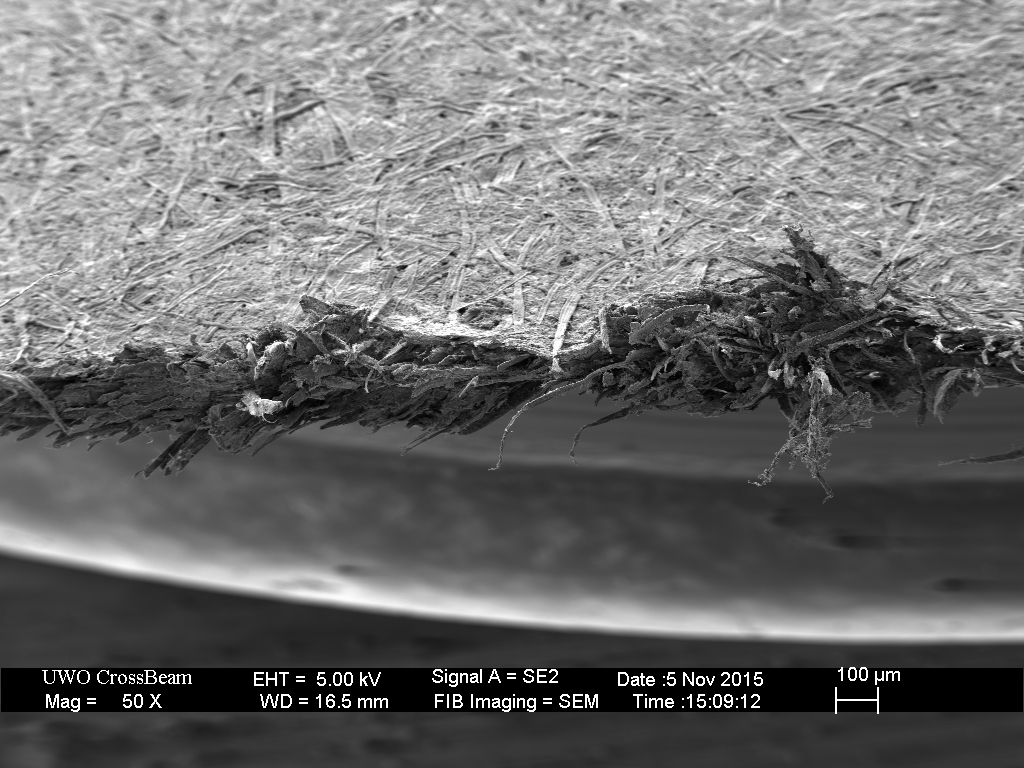

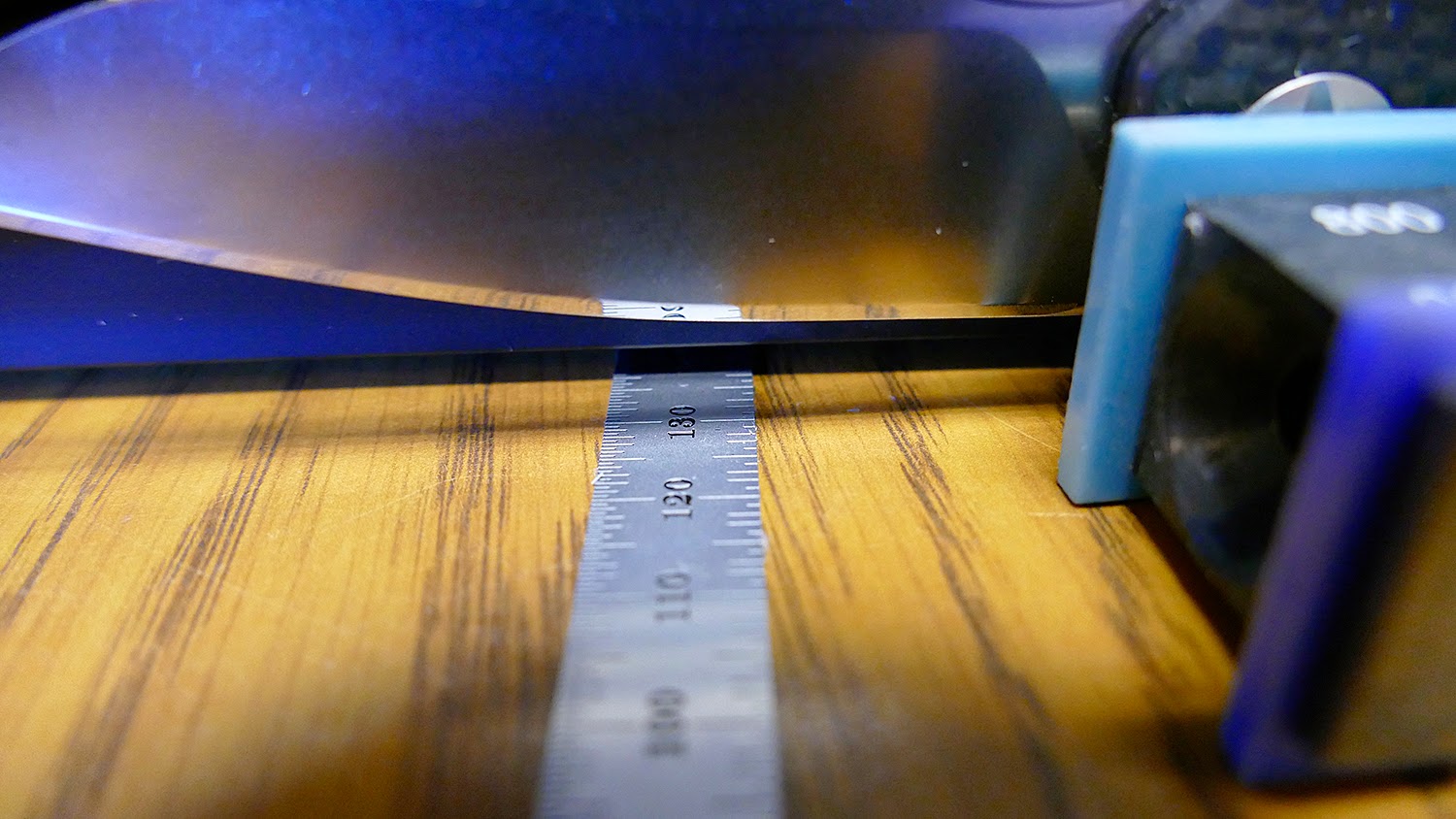

Why though? What makes it good for scalpels? Why does this method seem to give considerably longer edge retention cutting rope? I would think rope would be not dissimilar to other common materials that we use a knife on in EDC."There is no bigger eye-opener than a good 20X loupe on a freshly sharpened blade." (c) not me

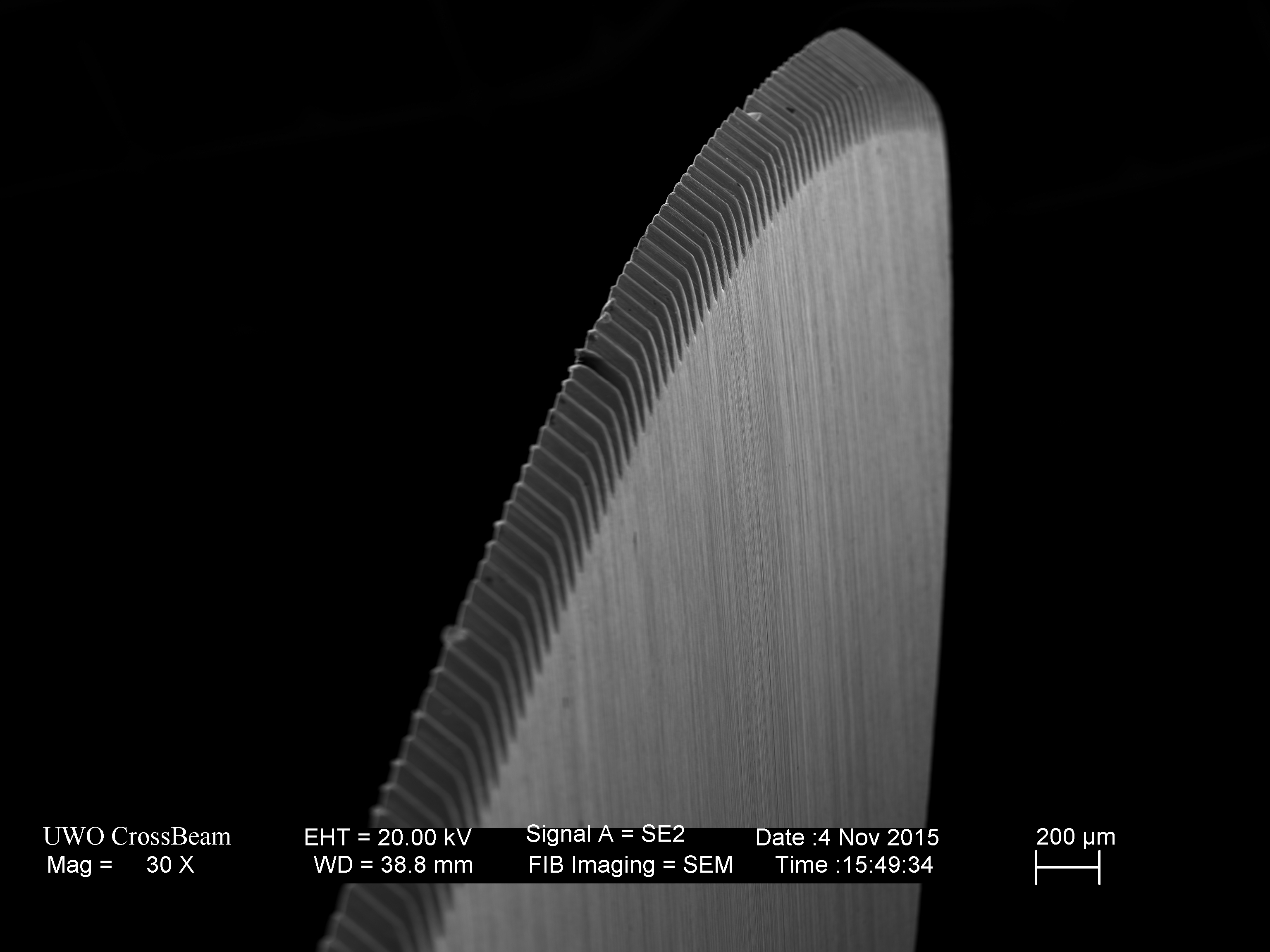

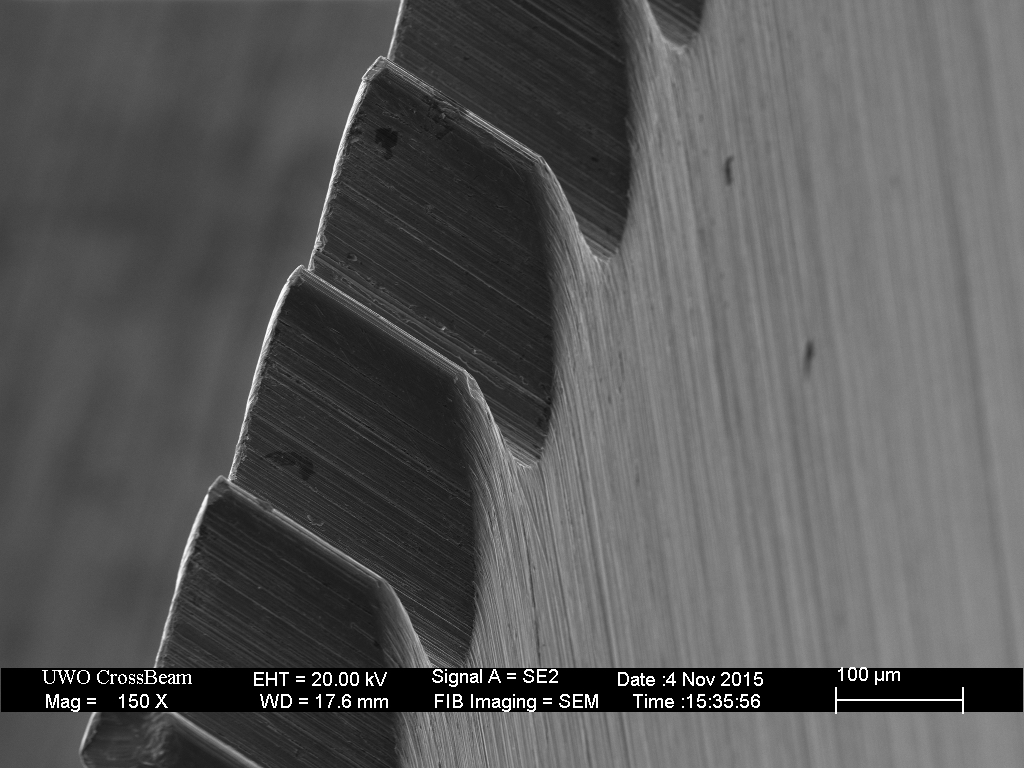

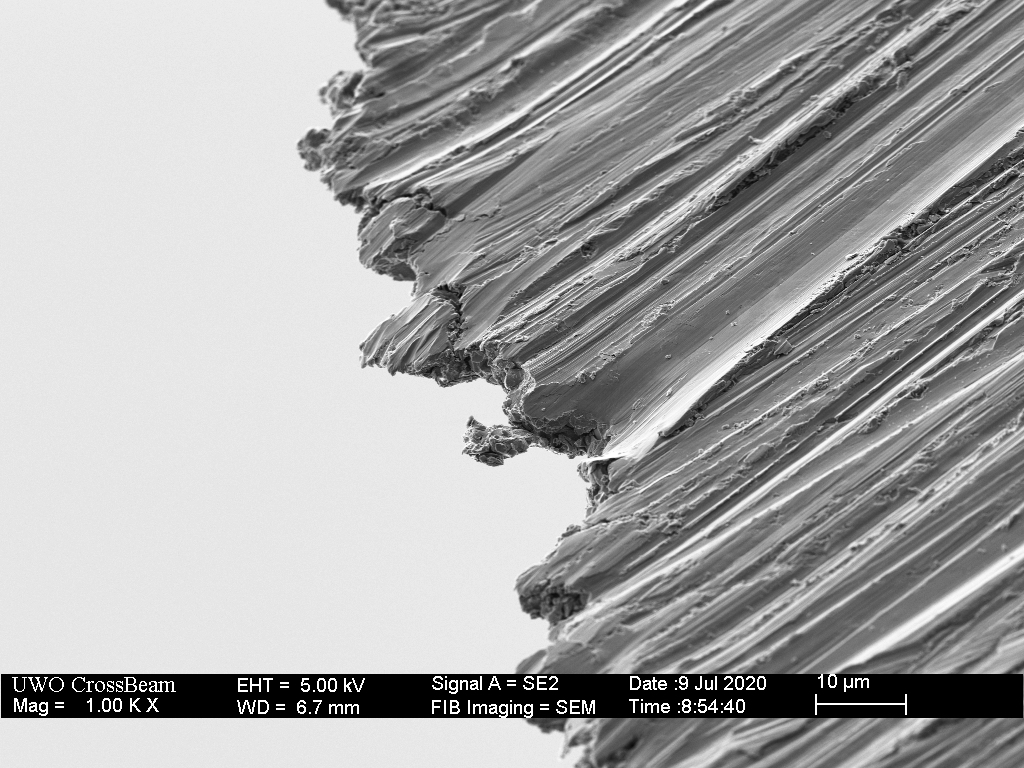

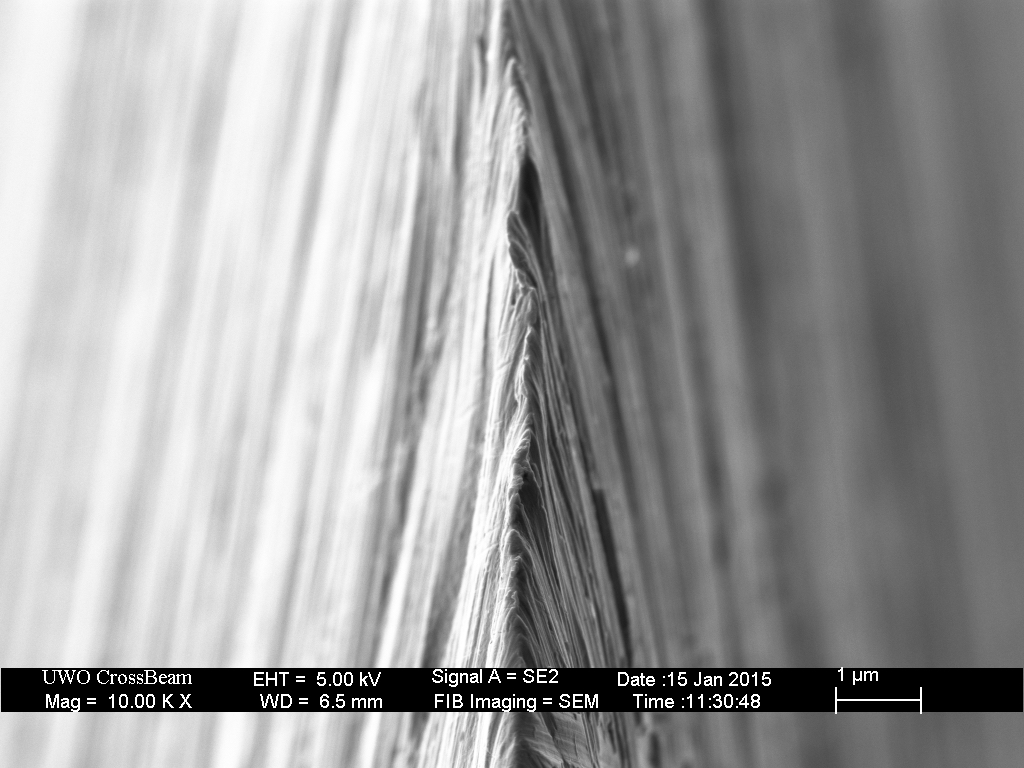

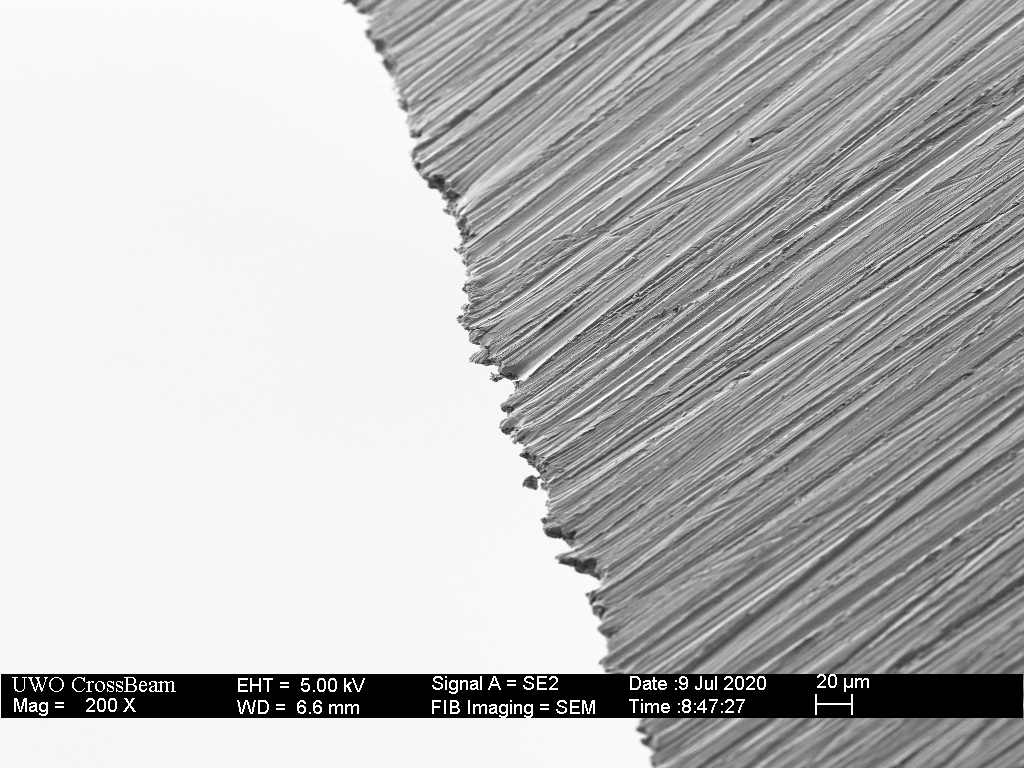

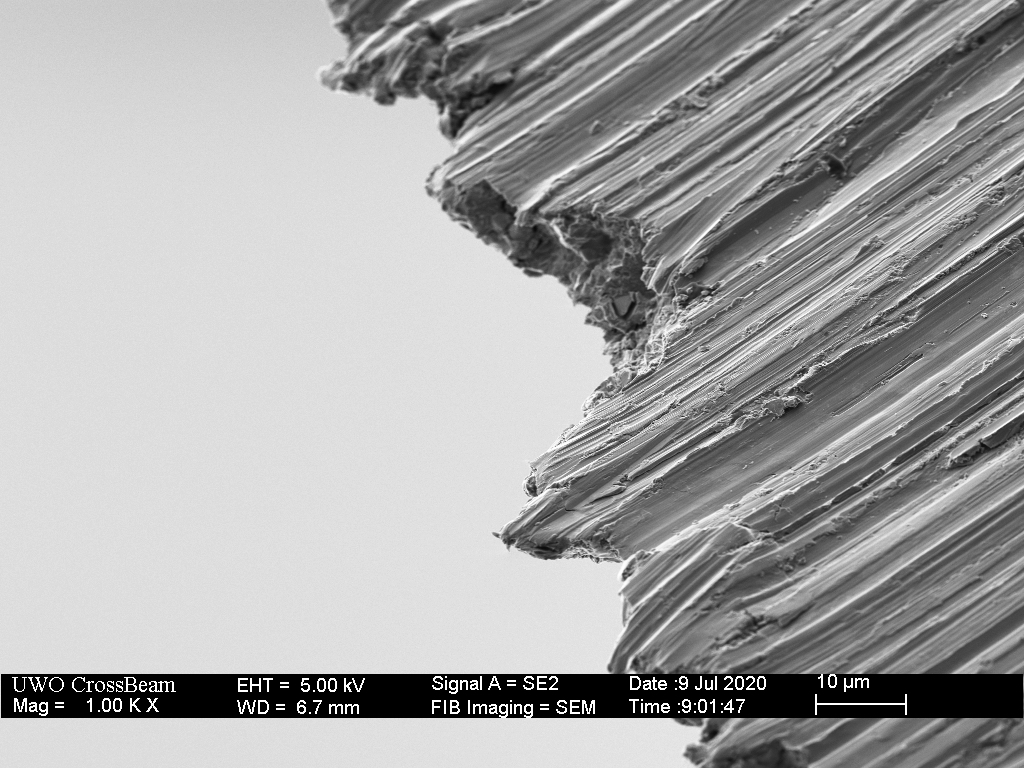

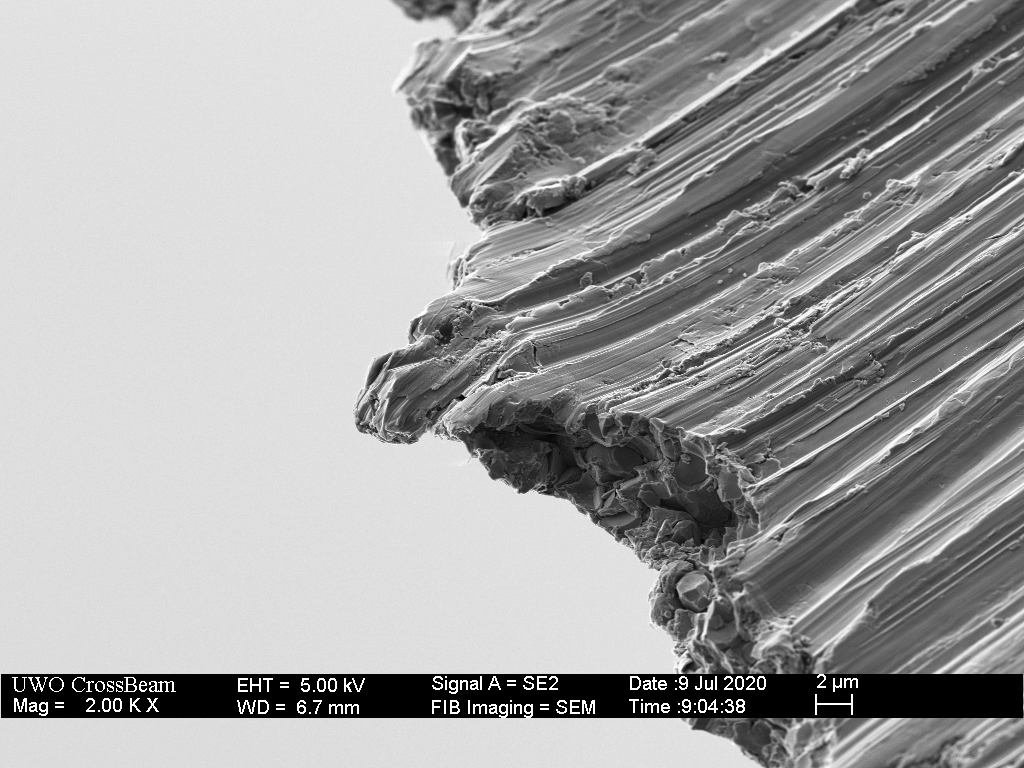

Microserration created by asymmetrical sharpening has two applications: scalpels and rope cutting competitions. Microserration wins competitions because of the cutting performance, not the edge retention that is very bad. People who studied the topic gave up after their first injuries. Hacksaw profile micro-serrator IS traumatic. Good for scalpels only.

I don't know either way. There are a lot of variables just in this particular set of tests, not least of which is the differences in sharpening method and skill. Just saying something is so doesn't add weight to the debate.

At least give the guy credit for trying something outside the square, even if it doesn't quite work the way he is thinking.