- Joined

- Feb 1, 2012

- Messages

- 13,727

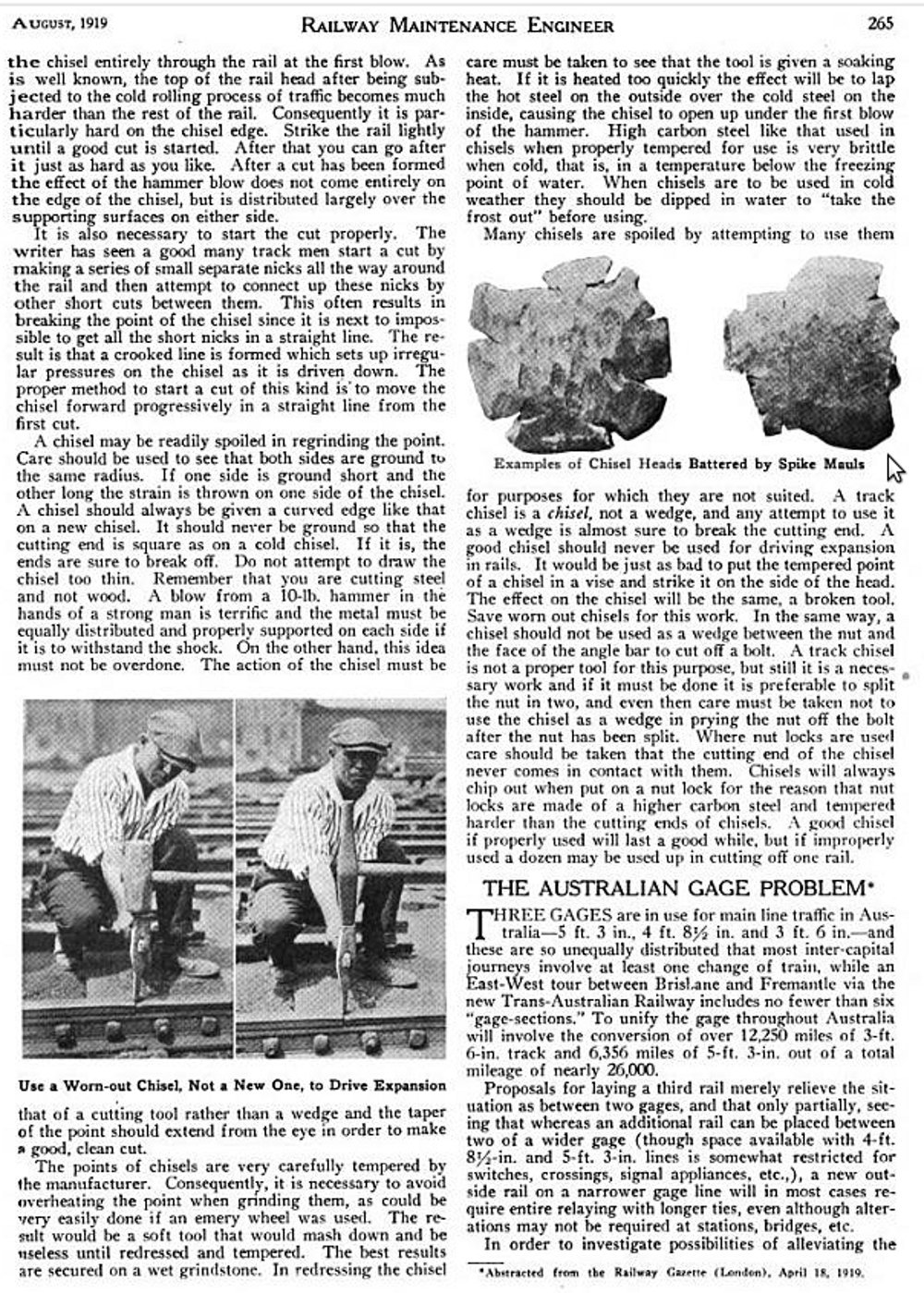

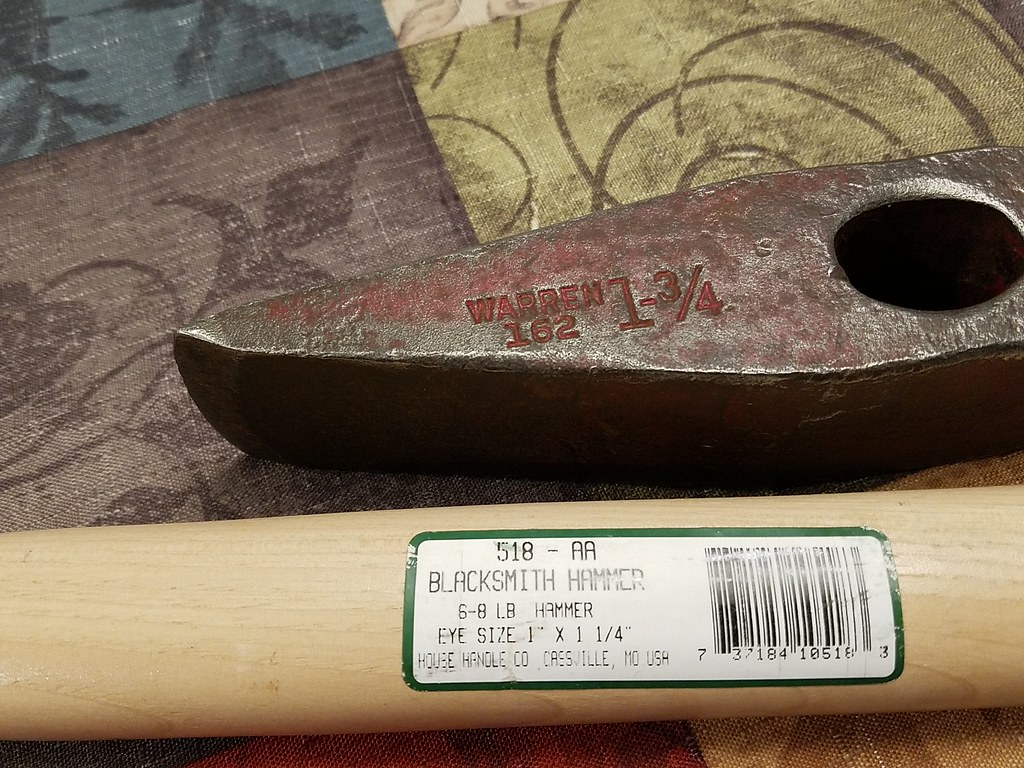

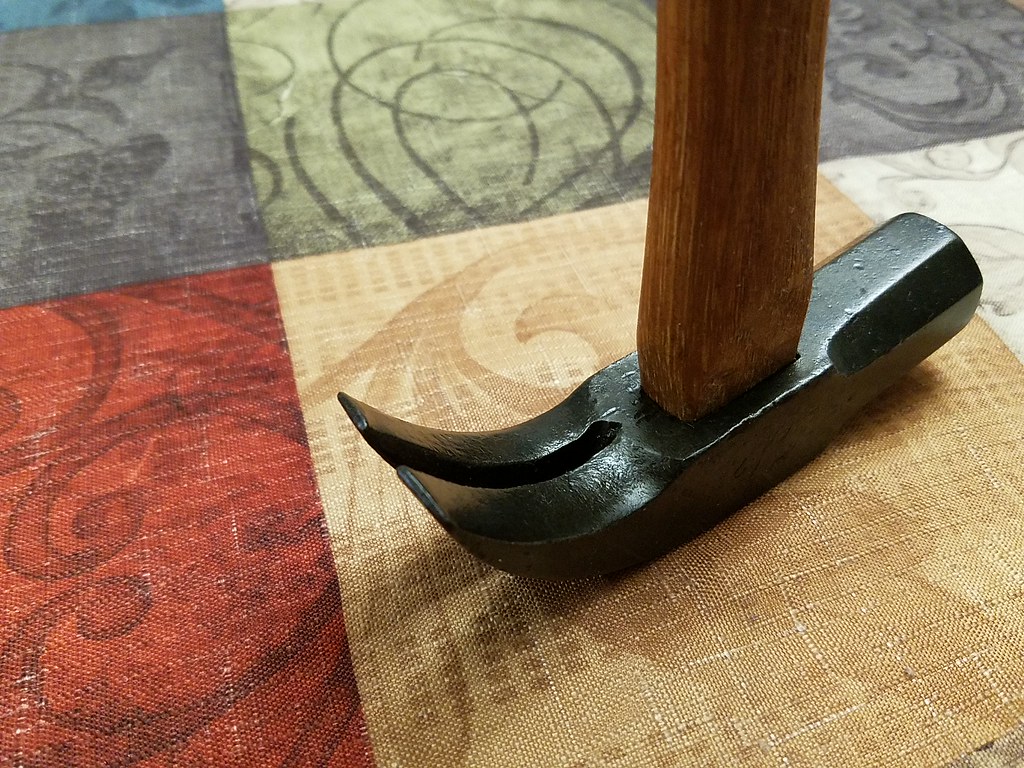

A track chisel should have a more rounded bit. My hunch is that you'll lose the heel and toe to chipping if you go at it with that.

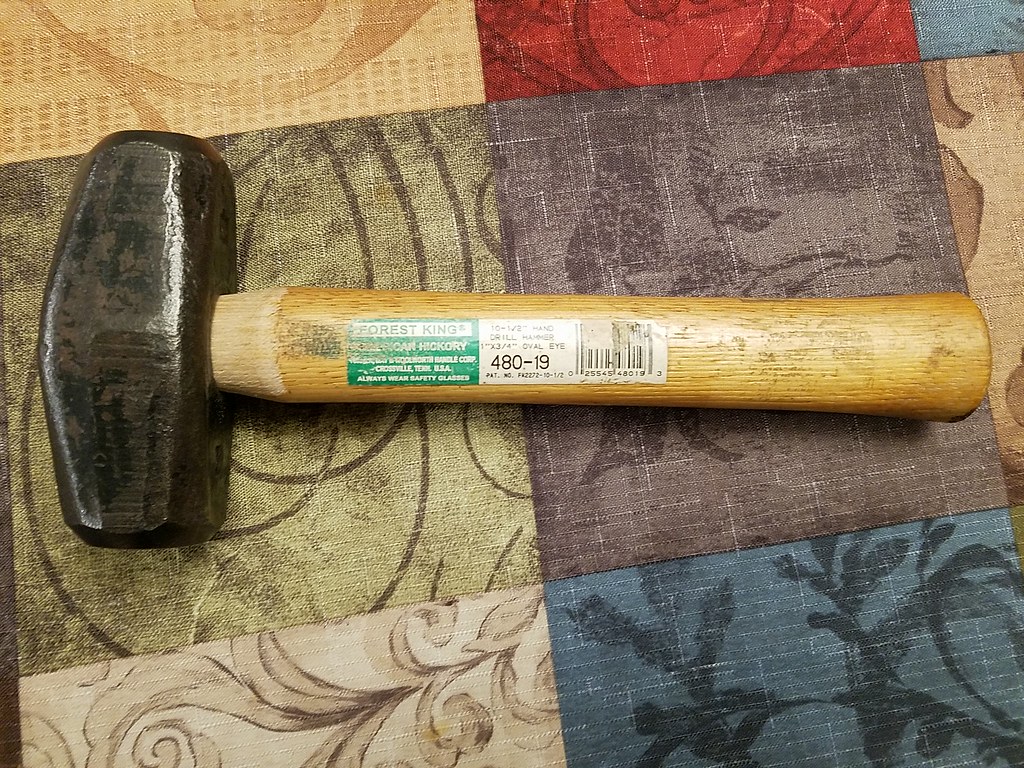

Also, I don't think you'll be successful actually dividing a 3 foot piece of track by that method. My understanding is that the track chisel was used to score the track all the way around. Then the portion to be removed was cantelevered over a tie and hammered hard with a sledge, tearing off the section track along the score line. The remaining end needs to be stable enough to resist the hammering.

If you hope to make this cut you'll need a means to stabilize your rail for the hammering.

Also, I don't think you'll be successful actually dividing a 3 foot piece of track by that method. My understanding is that the track chisel was used to score the track all the way around. Then the portion to be removed was cantelevered over a tie and hammered hard with a sledge, tearing off the section track along the score line. The remaining end needs to be stable enough to resist the hammering.

If you hope to make this cut you'll need a means to stabilize your rail for the hammering.

Last edited:

IMG_20171210_220536

IMG_20171210_220536 IMG_20171210_220551

IMG_20171210_220551 IMG_20171210_202758

IMG_20171210_202758 IMG_20171210_202842

IMG_20171210_202842 IMG_20171210_202837

IMG_20171210_202837 IMG_20171210_202849

IMG_20171210_202849 IMG_20171210_202902

IMG_20171210_202902 IMG_20171210_202857

IMG_20171210_202857 IMG_20171210_202907

IMG_20171210_202907

IMG_20171212_072059

IMG_20171212_072059 IMG_20171212_072140

IMG_20171212_072140 IMG_20171212_072218

IMG_20171212_072218 IMG_20171212_072228

IMG_20171212_072228 IMG_20171212_072322

IMG_20171212_072322 IMG_20171212_072354

IMG_20171212_072354 IMG_20171212_193818

IMG_20171212_193818 IMG_20171212_193827

IMG_20171212_193827 IMG_20171212_193909

IMG_20171212_193909 IMG_20171212_193848

IMG_20171212_193848