Thinking of switching out the single row steel bearings in my Civivi for something better for fidgeting and just messing around with. I'm not necessarily looking for the bearing with the least resistance, but more for the smoothest action possible. Would thrust roller bearings suit me best, or is there something better? Thanks in advance.

-

The BladeForums.com 2024 Traditional Knife is ready to order! See this thread for details: https://www.bladeforums.com/threads/bladeforums-2024-traditional-knife.2003187/

Price is $300 ea (shipped within CONUS). If you live outside the US, I will contact you after your order for extra shipping charges.

Order here: https://www.bladeforums.com/help/2024-traditional/ - Order as many as you like, we have plenty.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Recommendation? "Smoothest" type of bearing?

- Thread starter RichardBF

- Start date

Biochemdawg

Gold Member

- Joined

- Aug 11, 2018

- Messages

- 535

I think you’d achieve more by polishing all the points of contact rather than exchanging the bearings already in there..

ScooterG

You mean Ireland? Yeah, it’s mine.

- Joined

- Mar 15, 2016

- Messages

- 4,130

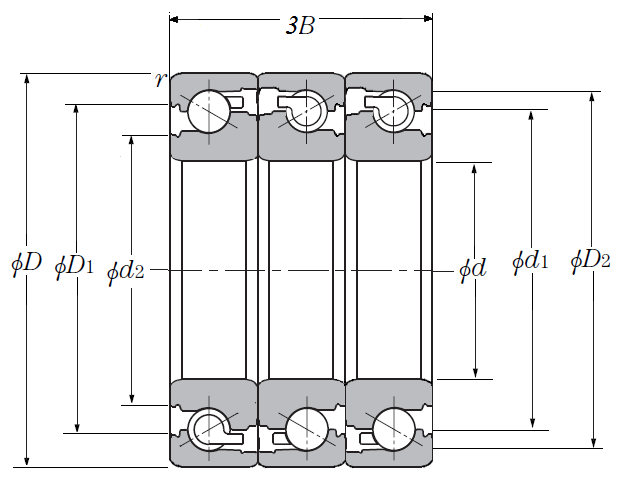

Triple row bearings are your best bet. Please share pics of the conversion.Thinking of switching out the single row steel bearings in my Civivi for something better for fidgeting and just messing around with. I'm not necessarily looking for the bearing with the least resistance, but more for the smoothest action possible. Would thrust roller bearings suit me best, or is there something better? Thanks in advance.

Last edited:

Another key aspect to smoothness is around lubrication. On bearing flippers some people use no lubrication, some use nano oil, but I find for the ultimate deployment I apply a controlled but hefty dose of synthetic red bearing grease. It takes a day of flipping to really work itself in then it is heaven on earth with my double row bearings (which I switched from steel to G5 ceramic - packet of 100 for <$10).

When you think of lubrication applications in the real world a) equipment designers generally use lubricant where metal rubs against metal b) oils are generally used in sump systems for applications generating high heat c) grease is typically used in bearing systems. There is a reason for this. Grease delivers uniform lubricity constantly and forms a cocoon around the moving metal bits keeping dirt and debris away from touching parts while delivering a film of lubrication. It can also be good deflecting moisture. Its is not the best for high heat conditions or applications with a lot of sacrificial wear... hopefully neither of those conditions exist with a knife.

When you think of lubrication applications in the real world a) equipment designers generally use lubricant where metal rubs against metal b) oils are generally used in sump systems for applications generating high heat c) grease is typically used in bearing systems. There is a reason for this. Grease delivers uniform lubricity constantly and forms a cocoon around the moving metal bits keeping dirt and debris away from touching parts while delivering a film of lubrication. It can also be good deflecting moisture. Its is not the best for high heat conditions or applications with a lot of sacrificial wear... hopefully neither of those conditions exist with a knife.

Another key aspect to smoothness is around lubrication. On bearing flippers some people use no lubrication, some use nano oil, but I find for the ultimate deployment I apply a controlled but hefty dose of synthetic red bearing grease. It takes a day of flipping to really work itself in then it is heaven on earth with my double row bearings (which I switched from steel to G5 ceramic - packet of 100 for <$10).

When you think of lubrication applications in the real world a) equipment designers generally use lubricant where metal rubs against metal b) oils are generally used in sump systems for applications generating high heat c) grease is typically used in bearing systems. There is a reason for this. Grease delivers uniform lubricity constantly and forms a cocoon around the moving metal bits keeping dirt and debris away from touching parts while delivering a film of lubrication. It can also be good deflecting moisture. Its is not the best for high heat conditions or applications with a lot of sacrificial wear... hopefully neither of those conditions exist with a knife.

Interesting. I use nano oil for now but i might get some bearing grease to try out now.

Triple row bearings are your best bet. Please share pics of the conversion.

What are triple row bearings? Can't seem to find any online

They can look like this.What are triple row bearings? Can't seem to find any online

- Joined

- Dec 5, 2018

- Messages

- 1,437

“Smoothness” is kind of vague and subjective, since people mean different things when they use the term. To me, it’s the sensation of how gritty or not the movement feels. In my Civivi Praxis, the action is noticeably grittier than any of my WE knives, which is likely due to the steel bearings instead of ceramic.

One of the benefits of ceramic is that they are almost perfectly round, and far more uniform than steel. The gritty feeling is, in part, the bearing being worn into something closer to a perfect sphere. Ceramic bearings are also incredibly smooth, so they’ve got less of an abrasive effect than steel. Think extremely fine grit vs. coarse sandpaper.

MRBS or roller bearings are going to increase friction through increased contact area, but also reduce the amount of pressure exerted on each ball (assuming equal pivot tension). Going from steel ball bearings to ceramic (single or MRBS) will reduce that sensation.

One of the benefits of ceramic is that they are almost perfectly round, and far more uniform than steel. The gritty feeling is, in part, the bearing being worn into something closer to a perfect sphere. Ceramic bearings are also incredibly smooth, so they’ve got less of an abrasive effect than steel. Think extremely fine grit vs. coarse sandpaper.

MRBS or roller bearings are going to increase friction through increased contact area, but also reduce the amount of pressure exerted on each ball (assuming equal pivot tension). Going from steel ball bearings to ceramic (single or MRBS) will reduce that sensation.

evilgreg

Why so serious?

- Joined

- Dec 25, 2012

- Messages

- 4,092

The least resistance I've had in a knife pivot that was tightened down wasn't a Shiro or a Thorburn, it was on the Buck Marksman I owned. That thing felt like it was frictionless.

For bearing knives, I've own free, caged (single and multi-row) and roller bearing knives, and the smoothest of the bunch have all been IKBS, which sucks, because IKBS is a PITA to take apart and put back together, comparatively. My IKBS Jason Clark custom is ridiculously smooth, more so than any of the three Shiros I owned.

Not the most free-swinging, but the smoothest action on any knife I currently own might be on my ZT 0850, a knife that runs on washers. I own literally dozens of flippers on bearings, but none of them feel better than the silky smooth glide of my 0850. Maybe mine has washers cut from angel wings or something, but it's effortlessly smooth. It falls shut and middle finger flicking it is ridiculously easy.

For bearing knives, I've own free, caged (single and multi-row) and roller bearing knives, and the smoothest of the bunch have all been IKBS, which sucks, because IKBS is a PITA to take apart and put back together, comparatively. My IKBS Jason Clark custom is ridiculously smooth, more so than any of the three Shiros I owned.

Not the most free-swinging, but the smoothest action on any knife I currently own might be on my ZT 0850, a knife that runs on washers. I own literally dozens of flippers on bearings, but none of them feel better than the silky smooth glide of my 0850. Maybe mine has washers cut from angel wings or something, but it's effortlessly smooth. It falls shut and middle finger flicking it is ridiculously easy.

- Joined

- Sep 20, 2015

- Messages

- 7,639

Yup.I think you’d achieve more by polishing all the points of contact rather than exchanging the bearings already in there..

The smoothest bearings are going to be the bearings in the most accurately made knife.

sharp_edge

Gold Member

- Joined

- Jul 30, 2015

- Messages

- 5,890

I imagine single row bearings with only three balls would be the smoothest although the durability may suffer. Does any manufacturer produce such a knife?

- Joined

- Dec 5, 2018

- Messages

- 1,437

I imagine single row bearings with only three balls would be the smoothest although the durability may suffer. Does any manufacturer produce such a knife?

You’d have to take a caged bearing and remove some balls.

- Joined

- Apr 22, 2015

- Messages

- 481

Perfectly flat highly polished washers are excellent and have the highest

load bearing surface...they are also not prone to brinelling.

Modern synthetic oils or greases on washers can yield amazing results.

Not sexy perhaps, but done correctly, heirloom grade.

Interface of the pivot/blade are also critical. Minimum play, and

perfect concentricity are required too.(IE superb machining)

load bearing surface...they are also not prone to brinelling.

Modern synthetic oils or greases on washers can yield amazing results.

Not sexy perhaps, but done correctly, heirloom grade.

Interface of the pivot/blade are also critical. Minimum play, and

perfect concentricity are required too.(IE superb machining)

CPP

Gold Member

- Joined

- Sep 8, 2014

- Messages

- 1,507

That would likely lead to horizontal blade playI imagine single row bearings with only three balls would be the smoothest although the durability may suffer. Does any manufacturer produce such a knife?

- Joined

- Jan 1, 2019

- Messages

- 340

In the past, I've been happy with a thorough cleaning and some good lubrication. I use Lubriplate SFL-0 and it does the trick. My Naja has decent action but would benefit from a stronger detent. My Baklash is just about perfect.

I never even though of swapping out bearings. Is that a thing? Forgive me not knowing the proper terminology but the bearings are caged in a washer of some kind. Can you just order up a new one that is better? Is there a standard size?

I never even though of swapping out bearings. Is that a thing? Forgive me not knowing the proper terminology but the bearings are caged in a washer of some kind. Can you just order up a new one that is better? Is there a standard size?

- Joined

- Dec 14, 2016

- Messages

- 1,144

Someone selling this on ebay, though it's not your CIVIVI knife you can still ask.