Stacy E. Apelt - Bladesmith

ilmarinen - MODERATOR

Moderator

Knifemaker / Craftsman / Service Provider

- Joined

- Aug 20, 2004

- Messages

- 37,721

TME has been mentioned quite a bit lately in Shop Talk posts- Tempered Martensite Embrittlement.

I want to hear from those who have actual metallurgy knowledge on the subject. It gets bandied around a lot, with many of the folks talking about it not really understanding how and why it happens, or if it is a problem in the world of knifemaking.

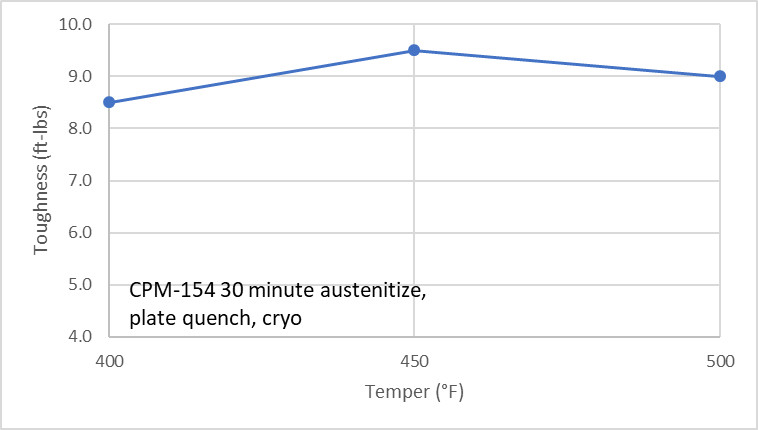

I understand that martensitic stainless steels have a problem with TME, but that is eliminated by tempering in the high range above 950°F. My question is concerning the carbon steels we use today. My concern is how and if TME affects the carbon steels we use.

1) My early studies (long ago) concerning TME had convinced me that it was not an issue in knives for the most part because the steels we use today are alloyed to control TME. As I understand it, this is mainly due to our modern steels having low S, P, and other impurities, which can decompose and precipitate carbides in tempering. The low percentage of these impurities reduces the susceptibility of carbon steels to TME. Is my understanding basically correct?

2) The addition of molybdenum raises the temperature range for TME. I see some trace of Mo in many analysis sheets. Is it there as a by-product of refining, or deliberate?

3) Does Manganese lower or raise the TME zone? I haven't found a good article on that.

4) What effect does the addition of small amounts of W, V, and Cr have on TME?

5) I see a lot of posts saying even a 400°F temper is too high. I didn't think TME would be a realistic concern until the 500-700F range? Many articles and charts show it at 700-900F.

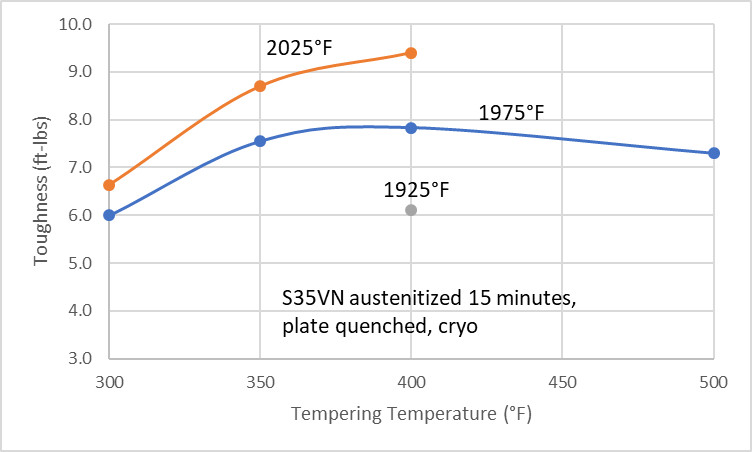

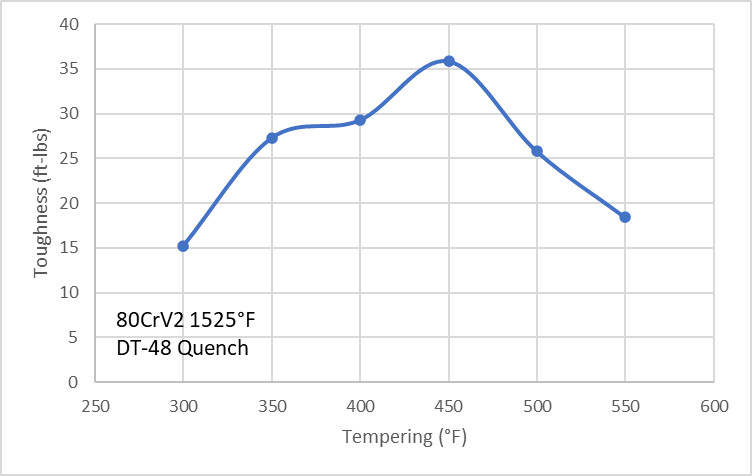

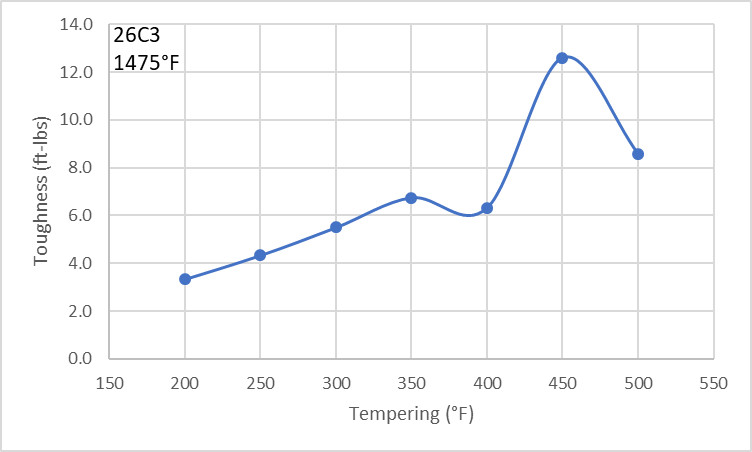

For simplicity, let's use some steels commonly in use today by knifemakers in our discussions. If thereare any commonly used knife carbon steels that deserve special note, please add them toy your replies - what would be the real-world concern in TME with a 450°F temper in 1084, 1095, 26C3, and something high alloy like Wolfram Special.

I'd like to hear what the metallurgists and metallurgical folks here think.

I was re-reading this University of Cambridge article by Bhadeshia:

His chapter (below) on TME seems interesting.

He talks about the issue at a much higher temperature than most folks use in Shop Talk

Both of the impurity-controlled embrittlement phenomena can be minimized by adding about 0.5 wt% molybdenum to the steel. The Mo associates with phosphorus atoms in the lattice thereby reducing mobility and hence the extent to which they segregate to boundaries. Larger concentrations of molybdenum are not useful because precipitation occurs.

In many bainitic microstructures, tempering even at temperatures as high as 550°C has only a small effect on cementite size and morphology. Consequently, the low--temperature embrittlement phenomena are not found in conventional bainitic microstructures.

NOTE: The article I linked has links to many other papers and articles on other metallurgy topics.

So, what are your thoughts????

I want to hear from those who have actual metallurgy knowledge on the subject. It gets bandied around a lot, with many of the folks talking about it not really understanding how and why it happens, or if it is a problem in the world of knifemaking.

I understand that martensitic stainless steels have a problem with TME, but that is eliminated by tempering in the high range above 950°F. My question is concerning the carbon steels we use today. My concern is how and if TME affects the carbon steels we use.

1) My early studies (long ago) concerning TME had convinced me that it was not an issue in knives for the most part because the steels we use today are alloyed to control TME. As I understand it, this is mainly due to our modern steels having low S, P, and other impurities, which can decompose and precipitate carbides in tempering. The low percentage of these impurities reduces the susceptibility of carbon steels to TME. Is my understanding basically correct?

2) The addition of molybdenum raises the temperature range for TME. I see some trace of Mo in many analysis sheets. Is it there as a by-product of refining, or deliberate?

3) Does Manganese lower or raise the TME zone? I haven't found a good article on that.

4) What effect does the addition of small amounts of W, V, and Cr have on TME?

5) I see a lot of posts saying even a 400°F temper is too high. I didn't think TME would be a realistic concern until the 500-700F range? Many articles and charts show it at 700-900F.

For simplicity, let's use some steels commonly in use today by knifemakers in our discussions. If thereare any commonly used knife carbon steels that deserve special note, please add them toy your replies - what would be the real-world concern in TME with a 450°F temper in 1084, 1095, 26C3, and something high alloy like Wolfram Special.

I'd like to hear what the metallurgists and metallurgical folks here think.

I was re-reading this University of Cambridge article by Bhadeshia:

His chapter (below) on TME seems interesting.

He talks about the issue at a much higher temperature than most folks use in Shop Talk

300→350°C Tempered-Martensite Embrittlement

This effect is common in clean steels, with fracture occurring transgranularly relative to the prior austenite grain boundaries. It is attributed to the formation of cementite particles at the martensite lath boundaries and within the laths. During tempering, the particles coarsen and become large enough to crack, thus providing crack nuclei which may then propagate into the matrix. As a consequence, untempered low--carbon martensitic steels sometimes have a better toughness than when they are tempered, even though the untempered steel is stronger. The cementite behaves like a brittle inclusion.Both of the impurity-controlled embrittlement phenomena can be minimized by adding about 0.5 wt% molybdenum to the steel. The Mo associates with phosphorus atoms in the lattice thereby reducing mobility and hence the extent to which they segregate to boundaries. Larger concentrations of molybdenum are not useful because precipitation occurs.

In many bainitic microstructures, tempering even at temperatures as high as 550°C has only a small effect on cementite size and morphology. Consequently, the low--temperature embrittlement phenomena are not found in conventional bainitic microstructures.

NOTE: The article I linked has links to many other papers and articles on other metallurgy topics.

So, what are your thoughts????

Last edited: