- Joined

- Oct 4, 2017

- Messages

- 528

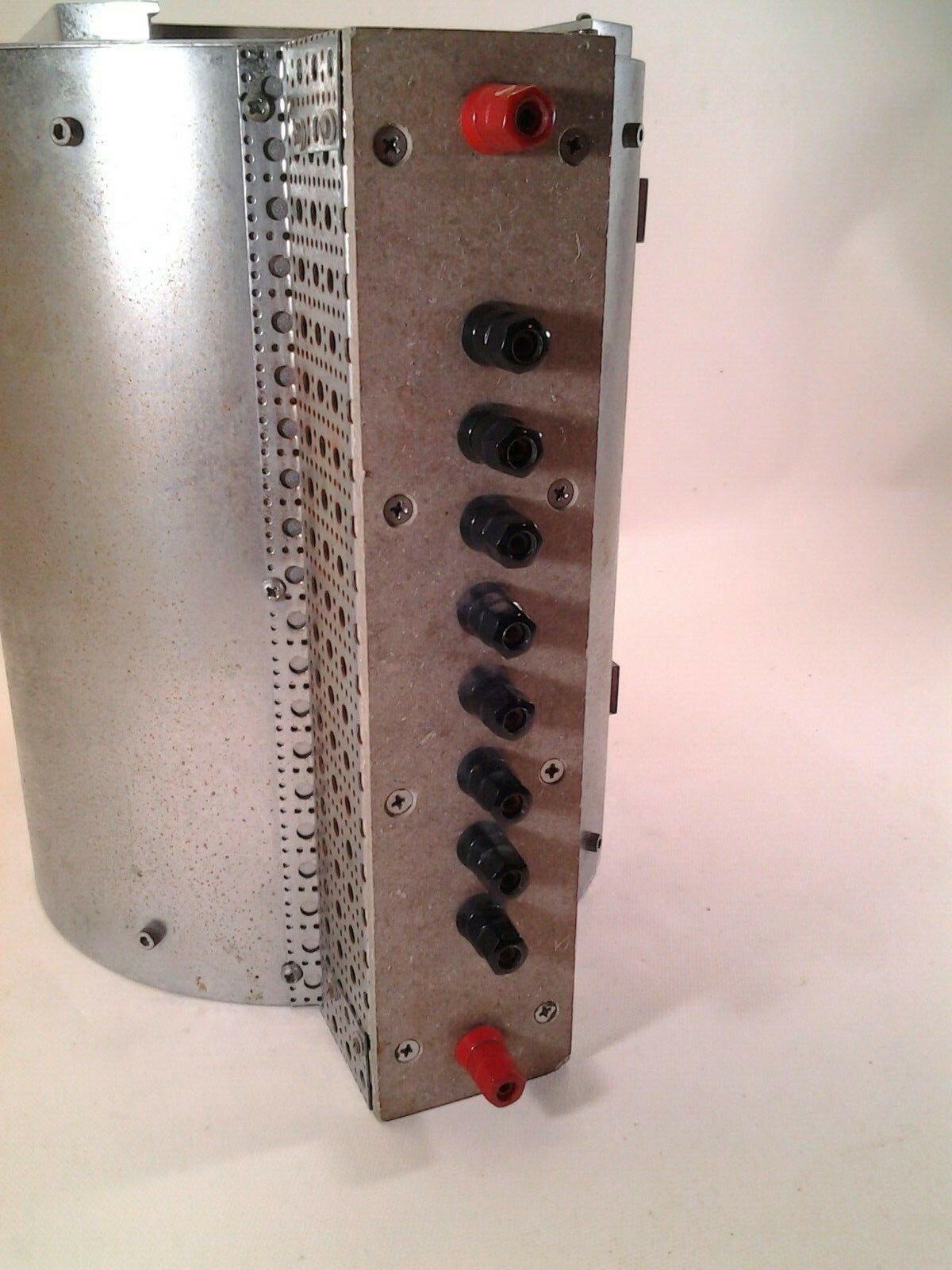

I have no idea how these things work but would they be usable for heat treating?

I don't see a plug but it says it is 110v. How would you set the temp?

https://www.ebay.com/itm/MARSHALL-T...614559?hash=item4b71f7d51f:g:qzQAAOSwFEhd9uzN

I don't see a plug but it says it is 110v. How would you set the temp?

https://www.ebay.com/itm/MARSHALL-T...614559?hash=item4b71f7d51f:g:qzQAAOSwFEhd9uzN