- Joined

- Oct 20, 2008

- Messages

- 5,547

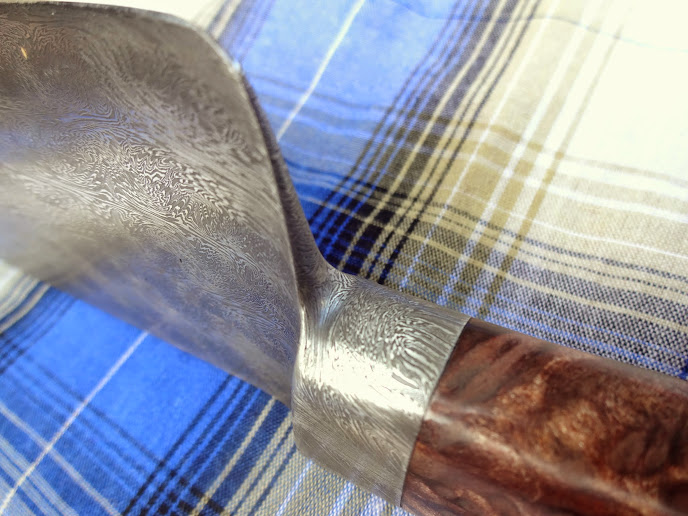

Up for your consideration is this rather extravagant 9 chef knife. The pattern welding represents probably my most involved adventure yet in damascus steel. The constituent steels are 15n20 and CruForge V. The CruForge offers some definitely enhanced cutting performance- I can definitely feel that it's a vanadium bearing steel, when cutting. Very sharp.

The pattern itself is 6 bars of twist/counter-twisted w's giving a multi-bar explosion pattern, albeit with a fine resolution. The tip was shaped using the forge welded bird's beak technique, to give a handsome visual pattern flow and minimize pattern distortion. The heel was forged directly into the bolster- indeed it is possible to see the bottom two bars of the edge being dragged up into the bolster area, a clue to the shaping process.

The edge is more of the French profile, long and shallowly curved, as is the classic Sabatier-inspired handle shape. The grip is fastened with a domed nickel silver pin for a touch of class, and the wood itself is some quite nice stabilized redwood burl with lots of eyes.

Cutting edge: 8-7/8

Total length: 13-7/8

Total weight: 7.5 oz.

Edge before sharpening: .007

Spine at bolster: .100

Heel height: 1-7/8

Asking price is $1200, NOW DROPPED TO $1000, which includes insured shipping to the U.S.A. For international rates, please inquire.

A picture is worth a thousand words... so here's several thousand word's worth, and a vid to boot! Thanks for checking it out.

[youtube]wpYNqfvkI6Y[/youtube]

The pattern itself is 6 bars of twist/counter-twisted w's giving a multi-bar explosion pattern, albeit with a fine resolution. The tip was shaped using the forge welded bird's beak technique, to give a handsome visual pattern flow and minimize pattern distortion. The heel was forged directly into the bolster- indeed it is possible to see the bottom two bars of the edge being dragged up into the bolster area, a clue to the shaping process.

The edge is more of the French profile, long and shallowly curved, as is the classic Sabatier-inspired handle shape. The grip is fastened with a domed nickel silver pin for a touch of class, and the wood itself is some quite nice stabilized redwood burl with lots of eyes.

Cutting edge: 8-7/8

Total length: 13-7/8

Total weight: 7.5 oz.

Edge before sharpening: .007

Spine at bolster: .100

Heel height: 1-7/8

Asking price is $1200, NOW DROPPED TO $1000, which includes insured shipping to the U.S.A. For international rates, please inquire.

A picture is worth a thousand words... so here's several thousand word's worth, and a vid to boot! Thanks for checking it out.

[youtube]wpYNqfvkI6Y[/youtube]

Last edited: