Contender Machine

Dealer / Materials Provider

- Joined

- Jun 23, 2015

- Messages

- 123

Well like many other knife makers on here when I saw the new Grizzly 2x42 belt grinder on the market I bought one immediately. The price of this thing is just crazy cheap. It’s easily the best grinder you can get for under $400 because well it‘s about the only grinder you can get for under $400. That being said it is cheap for a reason. The build quality and design is not the best as can be expected.

So naturally I did some upgrades! Since I make a living building grinders and grinder accessories I do intend to build and sell these upgrades to anyone who would like them but I thought I’d just start by sharing what I have done so far. I’d love to here any comments or ideas for further upgrades.

First thing I did was make new platen brackets as well as a simple steel platen. I made the brackets slotted so that it has adjustment both left to right (to center the platen up to the belt better) as well as adjustment in and out to allow for running radius platens. I haven’t made any radius platens yet though. Would anyone be interested in radius platens for this grinder?

Here‘s the new platen and brackets mounted in the stock platen frame. The new brackets allow better access to both sides of the platen.

The next thing I did was make a couple of new work rests. I made a 5x12 inch work rest that can tilt both forward and back 15 degrees. This along with tilting the platen itself allows for a wide range of angles. I also made a drop down work rest arm to allow for better jig grinding as it gives you access to more of the platen. By nature of the design you can only tilt back 15 degrees with the drop down arm. Tilting forward is limited because the work rest hits the arm.

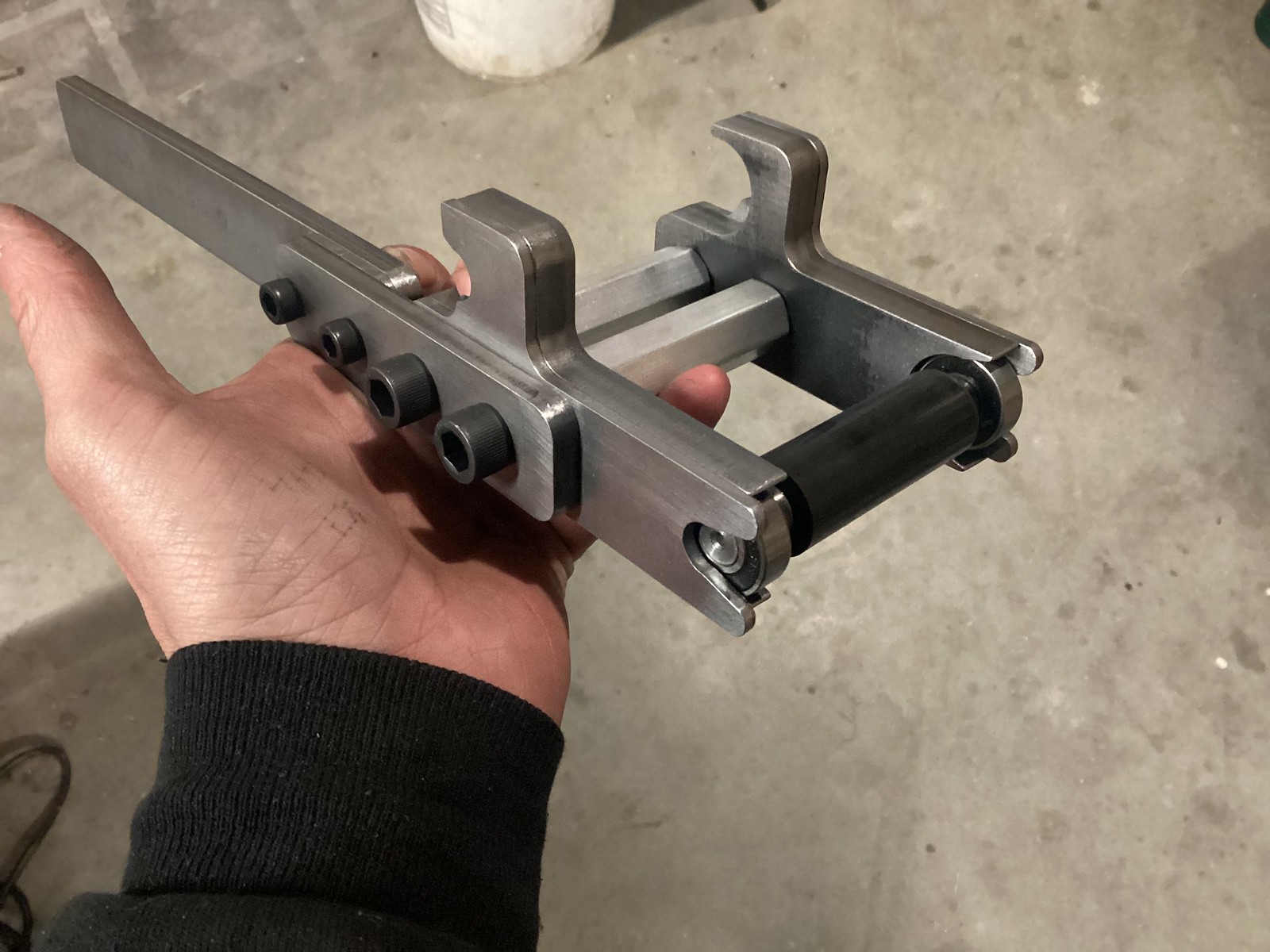

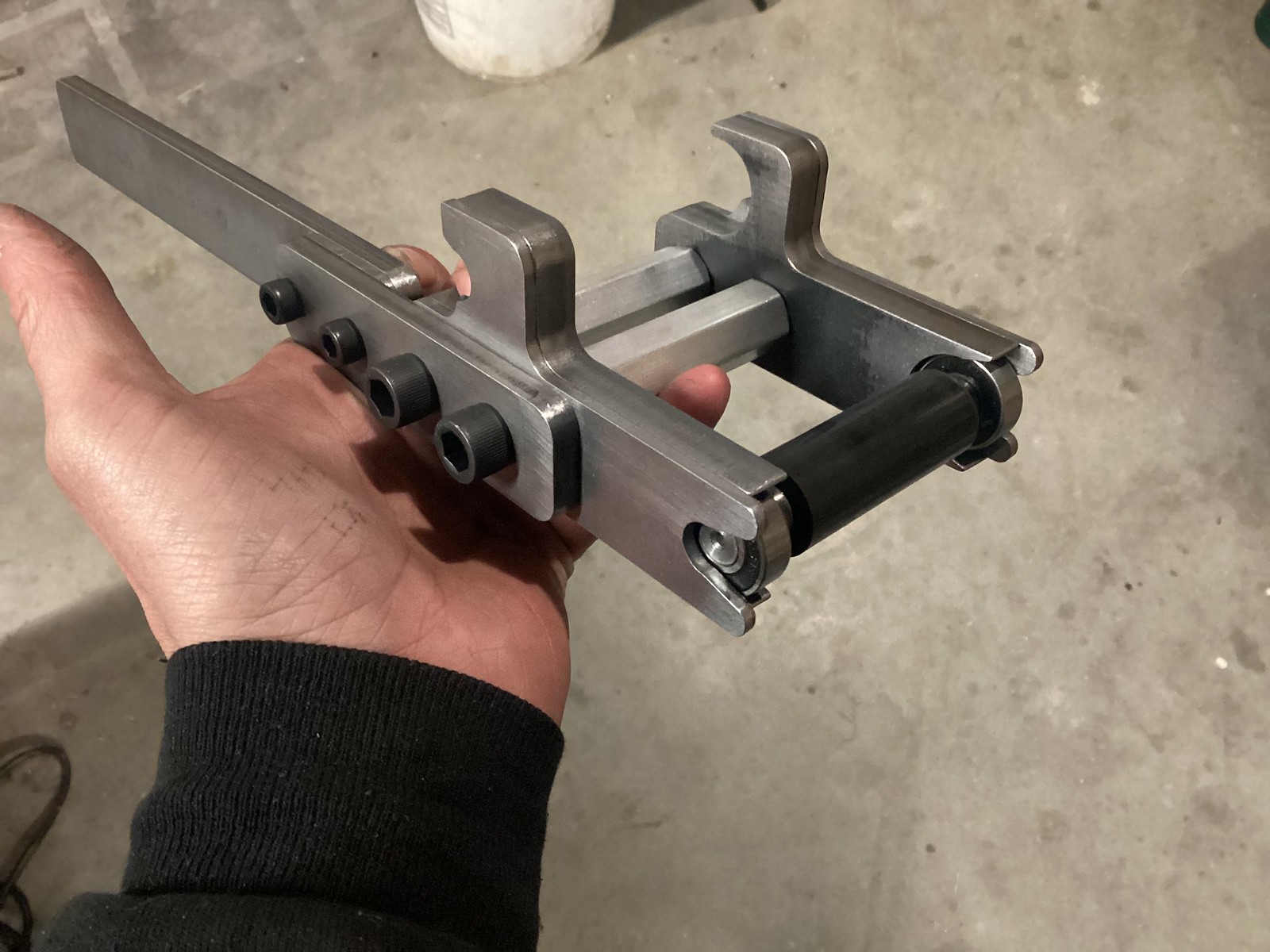

The last and probably most exciting thing I made was a small wheel attachment. This prototype is made to fit the standard small wheels that use 7/8 OD bearings with an overall length of about 3 1/8 inches. A lot of knife makers already have these wheels to use with there 2x72 so making the attachment use these wheels was the most practical. It accepts up to 2 wheels so that one acts to flatten the belt out.

This works really well.

Since this is a very cheap grinder to start with I had to design these attachments to be cheap and quick to make. It’s mostly just laser cut steel with some drilled and tapped holes and some milled slots. They went together very nicely and seem to run very well.

I intend to have both some flat and radius platens heat treated to make them hold up a lot better to the heat and belt wear.

Let me know what you guys think and if any of you would be interested in adding these upgrades to your new grinder as well! As always I’m open to suggestions!

So naturally I did some upgrades! Since I make a living building grinders and grinder accessories I do intend to build and sell these upgrades to anyone who would like them but I thought I’d just start by sharing what I have done so far. I’d love to here any comments or ideas for further upgrades.

First thing I did was make new platen brackets as well as a simple steel platen. I made the brackets slotted so that it has adjustment both left to right (to center the platen up to the belt better) as well as adjustment in and out to allow for running radius platens. I haven’t made any radius platens yet though. Would anyone be interested in radius platens for this grinder?

Here‘s the new platen and brackets mounted in the stock platen frame. The new brackets allow better access to both sides of the platen.

The next thing I did was make a couple of new work rests. I made a 5x12 inch work rest that can tilt both forward and back 15 degrees. This along with tilting the platen itself allows for a wide range of angles. I also made a drop down work rest arm to allow for better jig grinding as it gives you access to more of the platen. By nature of the design you can only tilt back 15 degrees with the drop down arm. Tilting forward is limited because the work rest hits the arm.

The last and probably most exciting thing I made was a small wheel attachment. This prototype is made to fit the standard small wheels that use 7/8 OD bearings with an overall length of about 3 1/8 inches. A lot of knife makers already have these wheels to use with there 2x72 so making the attachment use these wheels was the most practical. It accepts up to 2 wheels so that one acts to flatten the belt out.

This works really well.

Since this is a very cheap grinder to start with I had to design these attachments to be cheap and quick to make. It’s mostly just laser cut steel with some drilled and tapped holes and some milled slots. They went together very nicely and seem to run very well.

I intend to have both some flat and radius platens heat treated to make them hold up a lot better to the heat and belt wear.

Let me know what you guys think and if any of you would be interested in adding these upgrades to your new grinder as well! As always I’m open to suggestions!