ChazzyP

Platinum Member

- Joined

- Dec 27, 2014

- Messages

- 8,542

I posted this in a thread that T.L.E.Sharp started called Sad Day for a BM Owner* regarding the off-centered blade in his new 560 Freek and his unsuccessful attempts at correction. Our resident Benchmade Design Engineer and Mod, Jimmy, posted a great solution that involved using the open blade for leverage and pressing it against a table or such to re-orient the pivot axis and bring the blade to center.

[*There's a fair amount of discussion on point at the linked thread.]

It was suggested that I start a new thread in order to make this how-to a bit easier to find. Mods--I'd like to keep this here in the Benchmade wing as there's so much chatter about off-center BM blades.

Many, if not most, of us are familiar with the methodology of loosening the handle's body screws and either trying to shift scale alignment front-to-back or wedging the blade in the direction desired before re-tightening the body screws. I've had fairly good luck with the latter and find it easier than trying to hold the re-alignment of the scales/slabs with one hand while re-tightening the body screws with the other. Unfortunately, while the movement being sought is extremely slight, one is fighting the tension at the pivot without much leverage. Take a look at my rather rude diagram below to see what we're trying to achieve.

The "blade" of the "knife" on the left is touching the right-hand liner/slab. For all intents and purposes, the angle between the blade and the pivot axis (the short cross) should be considered as fixed while the angle between it and the slabs is moveable to some degree. Note in the diagram that the right slab is forward of the left as indicated by the arrows and the pivot axis is clearly out-of-square with the body of the knife. What needs to be achieved is a re-alignment of the two sides, as indicated by the arrows at the knife on the right, which will bring the pivot axis back to square and the blade back to center.

Note that there may be other causal factors for poor centering, such as a warped/crooked blade or poor milling. This method should at least help in those cases within the tolerances for movement at the pivot and body screws.

Anyway, per Jimmy's suggestion, an open blade will provide exponentially greater leverage when trying to re-align the axis and I figured that setting the blade in a vise would provide more control, ease of manipulation, and a greater modicum of safety. The other advantage of a clamped blade is that one needn't fight any bending along its length from tip to pivot.

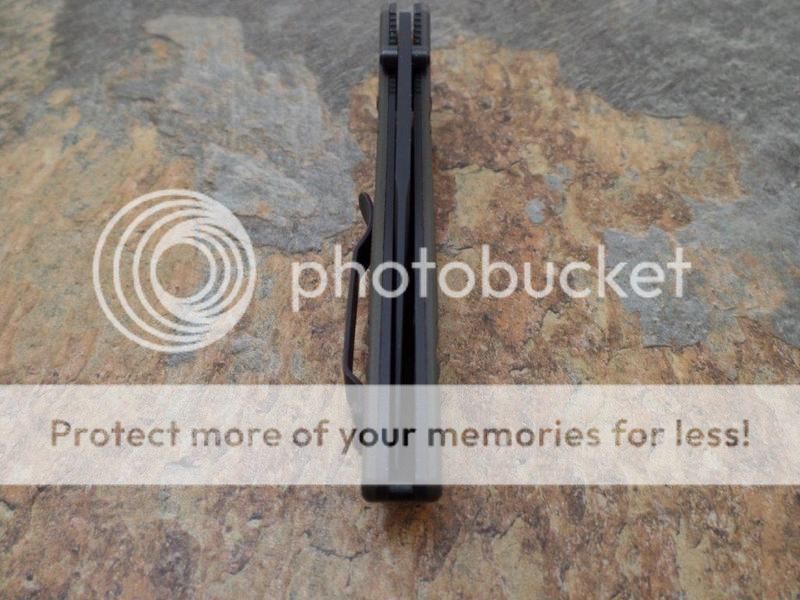

I'd never been able to get my first 710 entirely centered. The knife was bought used in"good" shape off the big river site--what did I know, I was a noob--and was pretty much a mess when I got it. I've put quite a bit into rehabbing her--she's my "rescue knife" and a great favorite. Among other fixes, the Delrin backspacer has been replaced with Gnoleb dumbbell-style standoffs and you can judge the poor alignment against the center portion of the back standoff.

I folded a piece of corrugated cardboard for protection and clamped the blade in the bench-vise. With the knife set up thusly it's easy to access the body screws from either or both sides as required.

My blade was off to the left as viewed in these pictures (opposite direction from my diagram above). Jimmy talked about holding the knife in hand and pushing the blade against a table in the direction that it's off (which he described as seeming "backwards"). With the open blade fixed in the vise, I loosened the two body screws and pushed the handle to the left--indicated by the torx-driver--so the blade, when closed, would move to the right. This is perhaps more intuitive as one can more easily imagine the spacing between the slabs and a closed blade changing in the proper direction. Holding it firm with my left hand, it was easy to access the torx screw heads on the right side to re-tighten them.

Note that only the body screws should be loosened/re-tightened while re-aligning. The pivot screws should be left alone until the centering process is complete.

After tightening everything up, the blade was actually a tiny bit too-far-right and the action that had been fairly free-dropping was stiff and tight. Backing off the pivot in two slight increments brought it back to dead-balls center and loosened it right up without resulting in any blade-play whatsoever. In fact, the action is even better now, completely free-dropping closed using only my thumb--pure Benchmade heaven!

Jimmy has also suggested that it's not necessary to loosen the body screws to effect the correction needed. To my mind, one has more control and must exert less force when the knife is rigidly held and you're not fighting to shift slabs that are tightly tied together. Whatever works for you, I hope you find this useful.

--Steve

[*There's a fair amount of discussion on point at the linked thread.]

It was suggested that I start a new thread in order to make this how-to a bit easier to find. Mods--I'd like to keep this here in the Benchmade wing as there's so much chatter about off-center BM blades.

Many, if not most, of us are familiar with the methodology of loosening the handle's body screws and either trying to shift scale alignment front-to-back or wedging the blade in the direction desired before re-tightening the body screws. I've had fairly good luck with the latter and find it easier than trying to hold the re-alignment of the scales/slabs with one hand while re-tightening the body screws with the other. Unfortunately, while the movement being sought is extremely slight, one is fighting the tension at the pivot without much leverage. Take a look at my rather rude diagram below to see what we're trying to achieve.

The "blade" of the "knife" on the left is touching the right-hand liner/slab. For all intents and purposes, the angle between the blade and the pivot axis (the short cross) should be considered as fixed while the angle between it and the slabs is moveable to some degree. Note in the diagram that the right slab is forward of the left as indicated by the arrows and the pivot axis is clearly out-of-square with the body of the knife. What needs to be achieved is a re-alignment of the two sides, as indicated by the arrows at the knife on the right, which will bring the pivot axis back to square and the blade back to center.

Note that there may be other causal factors for poor centering, such as a warped/crooked blade or poor milling. This method should at least help in those cases within the tolerances for movement at the pivot and body screws.

Anyway, per Jimmy's suggestion, an open blade will provide exponentially greater leverage when trying to re-align the axis and I figured that setting the blade in a vise would provide more control, ease of manipulation, and a greater modicum of safety. The other advantage of a clamped blade is that one needn't fight any bending along its length from tip to pivot.

I'd never been able to get my first 710 entirely centered. The knife was bought used in"good" shape off the big river site--what did I know, I was a noob--and was pretty much a mess when I got it. I've put quite a bit into rehabbing her--she's my "rescue knife" and a great favorite. Among other fixes, the Delrin backspacer has been replaced with Gnoleb dumbbell-style standoffs and you can judge the poor alignment against the center portion of the back standoff.

I folded a piece of corrugated cardboard for protection and clamped the blade in the bench-vise. With the knife set up thusly it's easy to access the body screws from either or both sides as required.

My blade was off to the left as viewed in these pictures (opposite direction from my diagram above). Jimmy talked about holding the knife in hand and pushing the blade against a table in the direction that it's off (which he described as seeming "backwards"). With the open blade fixed in the vise, I loosened the two body screws and pushed the handle to the left--indicated by the torx-driver--so the blade, when closed, would move to the right. This is perhaps more intuitive as one can more easily imagine the spacing between the slabs and a closed blade changing in the proper direction. Holding it firm with my left hand, it was easy to access the torx screw heads on the right side to re-tighten them.

Note that only the body screws should be loosened/re-tightened while re-aligning. The pivot screws should be left alone until the centering process is complete.

After tightening everything up, the blade was actually a tiny bit too-far-right and the action that had been fairly free-dropping was stiff and tight. Backing off the pivot in two slight increments brought it back to dead-balls center and loosened it right up without resulting in any blade-play whatsoever. In fact, the action is even better now, completely free-dropping closed using only my thumb--pure Benchmade heaven!

Jimmy has also suggested that it's not necessary to loosen the body screws to effect the correction needed. To my mind, one has more control and must exert less force when the knife is rigidly held and you're not fighting to shift slabs that are tightly tied together. Whatever works for you, I hope you find this useful.

--Steve

Last edited: