SolarStorm50

Knifemaker / Craftsman / Service Provider

- Joined

- Dec 10, 2020

- Messages

- 155

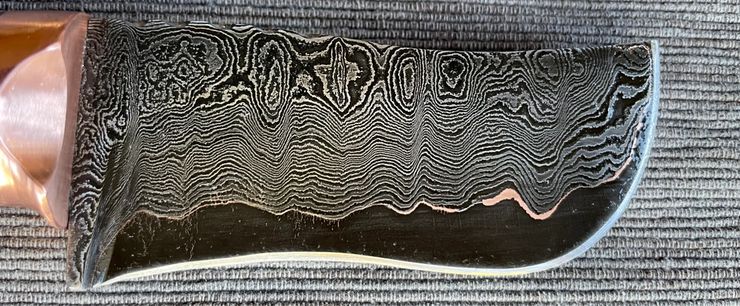

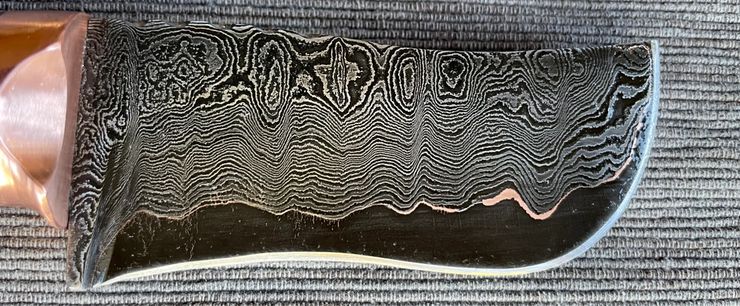

Commission to use the clients antler in a custom designed skinner. 3" cumai with with copper bolster and antler supplied by the customer. I put an article on my articles page on how I create my CuMai