There are lots of factors that matter for knife steel. I generally don't consider toughness for EDC knives as I won't be chopping, batoning, using them as levers, etc. I mostly care about edge retention and corrosion resistance. Increasing edge retention can mean increasing the amount of time it takes to sharpen, but it should ideally reduce the time between needing to be sharpened. While 8Cr isn't a big jump, you can reduce the workload for all your sharpening with better stones. Some steels also respond very well to stropping.

Steel matters but a given steel's properties be modified by heat treatment and good edge geometry. For instance, Buck does amazing things with 420HC that set it far above the average. That's the exception and not the rule. That's the reason a lot of people look down upon the 420 steels today.

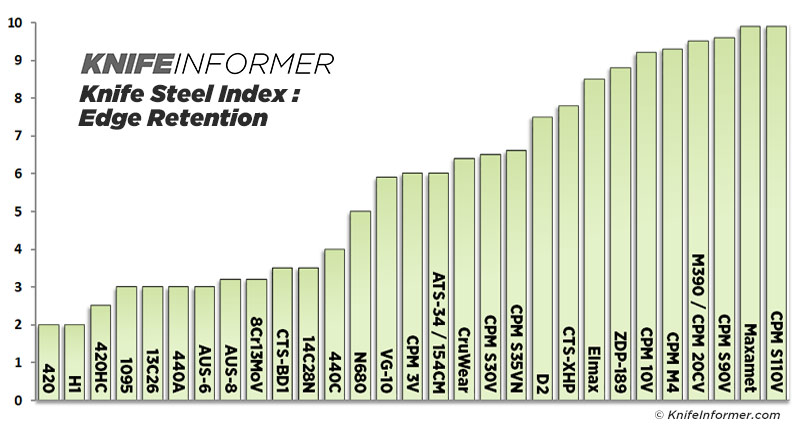

I've found that 8Cr13Mov is a little better than your average 420 steels. Take a look at the chart below. It's very general and remember that heat treatment can matter. (For instance, Buck's 420HC will place with slightly better steels and cheap 440C from Ganzo will place with slightly worse steels.) Chinese D2 tends to place lower but still better than 8Cr13Mov. There are also lots of steels not on the list, such as the 7Cr steels. In my experience, 7Cr tends to be in the same general ballpark as the 8Cr steels. The point is to consider the spectrum and look at what's available in the current market.

Given the current market, I wouldn't bother with 8Cr13Mov or less. There are just too many good options in better steels. Look at Ruike or Kershaw knives in 14C28N. Look at Civivi or Real Steel knives in 9Cr18Mov. If you want to try a real budget gem, check out the Tangram Santa Fe in Acuto 440.