Larrin

Knifemaker / Craftsman / Service Provider

- Joined

- Jan 17, 2004

- Messages

- 4,970

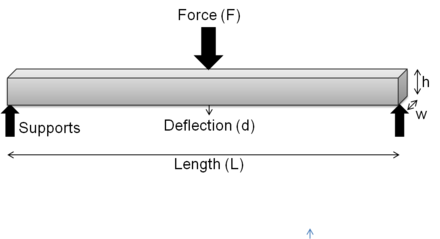

You took a line labeled “plastic deformation” and instead called it “elasticity.” You interpreted the whole thing backwards.I interpreted chart as: 'plastic deformation' line/curve corresponding to yield strength and 'total deflection' to fracture strength. Perhaps you have a better or right way to interpret the chart? Please just state your opinion rather than being young about it.