- Joined

- Jan 15, 2015

- Messages

- 446

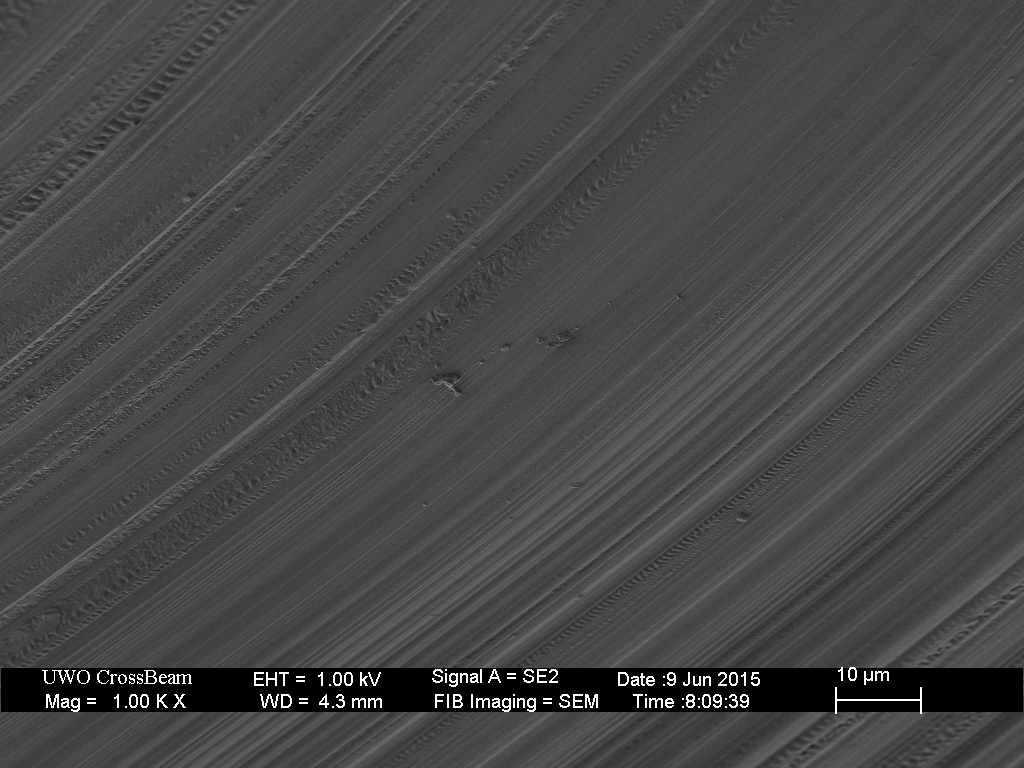

Can you guys make out that ring-like artifact that is formed just shy of the outer edge of the media? In some instances it disrupts the striations, interrupting the straightness of the lines, other times it is actually protruded, and others seems sunken beneath the surface. In fact in some of the instances it seems like it's almost been stretched out.

It appears that both the BESS media and Josh's fishing line have an outer shell. I suspect the fishing line shell provides more secure knotting.

It looks like the stropped edge cuts most of the way through then the last bit stretches and breaks.

The striations in the coarse-honed blade result from cutting (smooth) in the sharp areas of the blade and ripping/stretching (rough) along the path of the dull areas of the blade.