- Joined

- Mar 20, 2019

- Messages

- 132

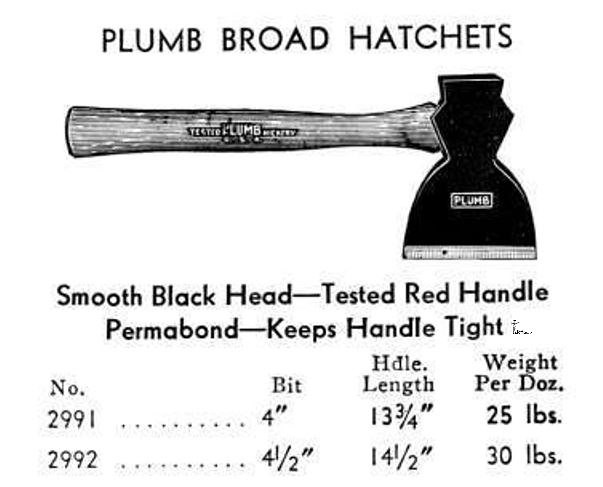

I've always called them carpenter's hand axes, they are flat on one side with the bevel on the other, like a one handed small broad axe. Hatchet sized. Bevel is on the right side, flat on the left side. I picked one up at the fleamarket recently for $10, rusty with a couple of notches in the blade , like someone was cutting a hard screw. This one has red epoxy suggesting maybe Plumb, but no red stain or makers mark. It was sharpened both sides, no surprise there, straight, slightly down at the toe. I think it needs to be shaped, as well as being sharpened. I need help from an experts here. After four google searches, I did find an image of a Plumb, it sure looks like it. THX

I've been enjoying the reading.

I've been enjoying the reading.