Right I totally understand.

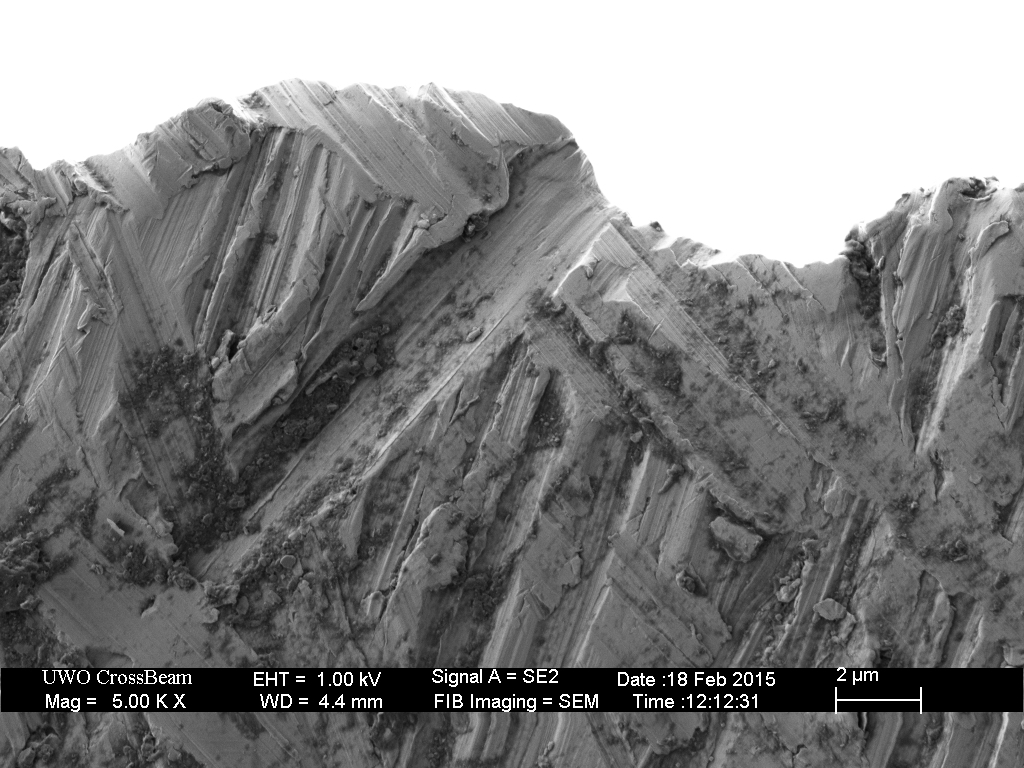

The image furnished by Mr. Wizard is neither - perfectly uniform or typical - it is as close to ideal as possible - it looks pristine because it has yet to be used and will deform markedly in less than one stroke - fact.

So any cutting ability is pure conjecture and is not repeatable with the scientific method with a multitude of variables.

We will have to agree to disagree.

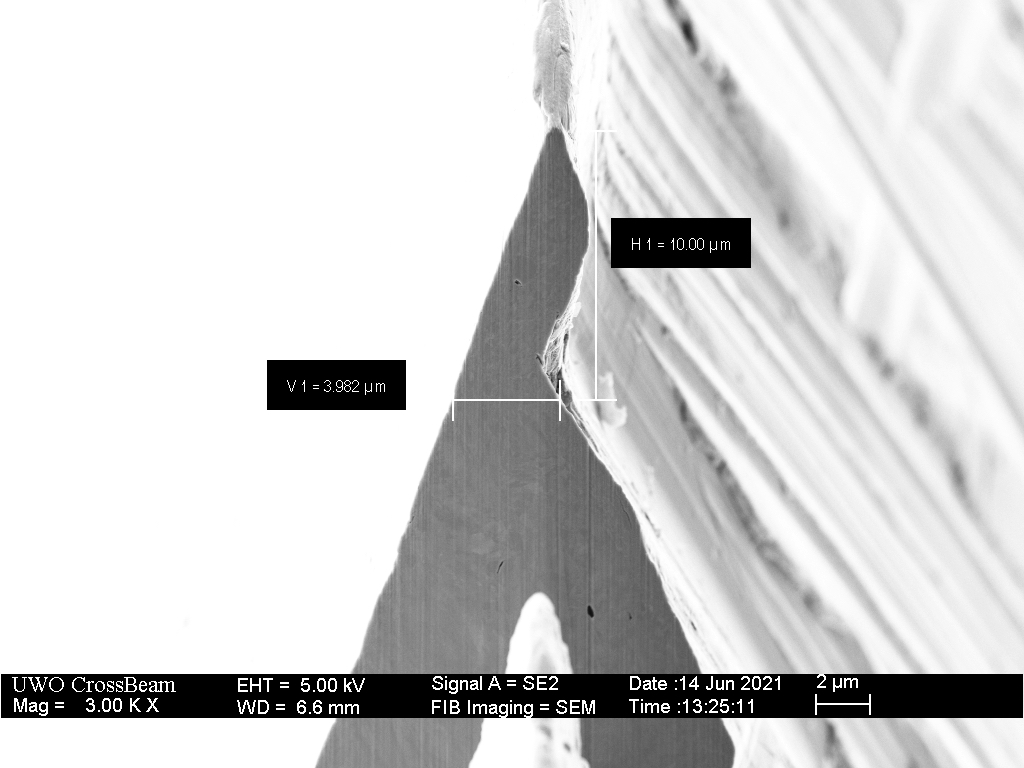

When I see an edge like that cut something as efficiently as a mildly serrated edge with before and after microscopy I will eat my words with pleasure.

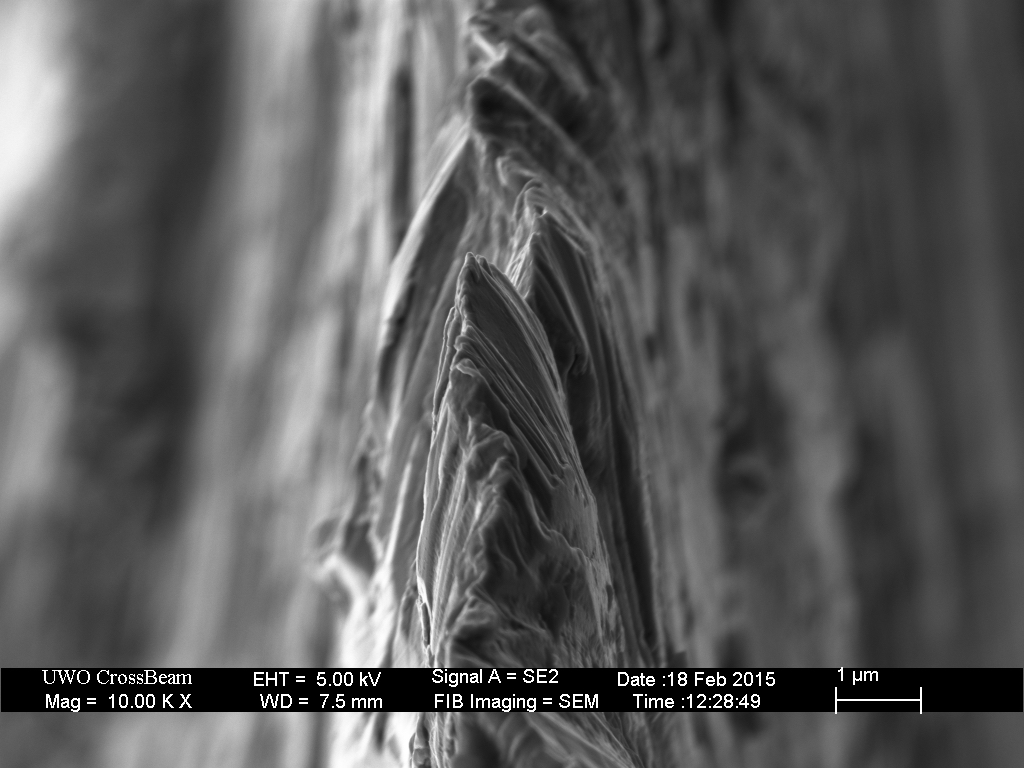

Notice I said a "stable" apex after use which is the crucial adjective.

That can not be dismissed and discounted.

It is theoretical because it has yet to be used in real life.

The image furnished by Mr. Wizard is neither - perfectly uniform or typical - it is as close to ideal as possible - it looks pristine because it has yet to be used and will deform markedly in less than one stroke - fact.

So any cutting ability is pure conjecture and is not repeatable with the scientific method with a multitude of variables.

We will have to agree to disagree.

When I see an edge like that cut something as efficiently as a mildly serrated edge with before and after microscopy I will eat my words with pleasure.

Notice I said a "stable" apex after use which is the crucial adjective.

That can not be dismissed and discounted.

It is theoretical because it has yet to be used in real life.

Last edited: