Brian.Evans

Registered Member

- Joined

- Aug 20, 2011

- Messages

- 3,267

I thought maybe you guys would like to see into the process a bit and see how I put the jimping onto the spine of a knife. This is Mike157's knife.

First the tools and victim. Bruce Bump carbide faced file guide and a Swiss Grobet 20 line per inch checkering file. These things both are expensive, but there is really no substitute for either. The ebony handle on the file is custom, by me. Lol. It's like holding a bar of soap, very smooth and super comfortable, which is handy when you're filing for an hour straight.

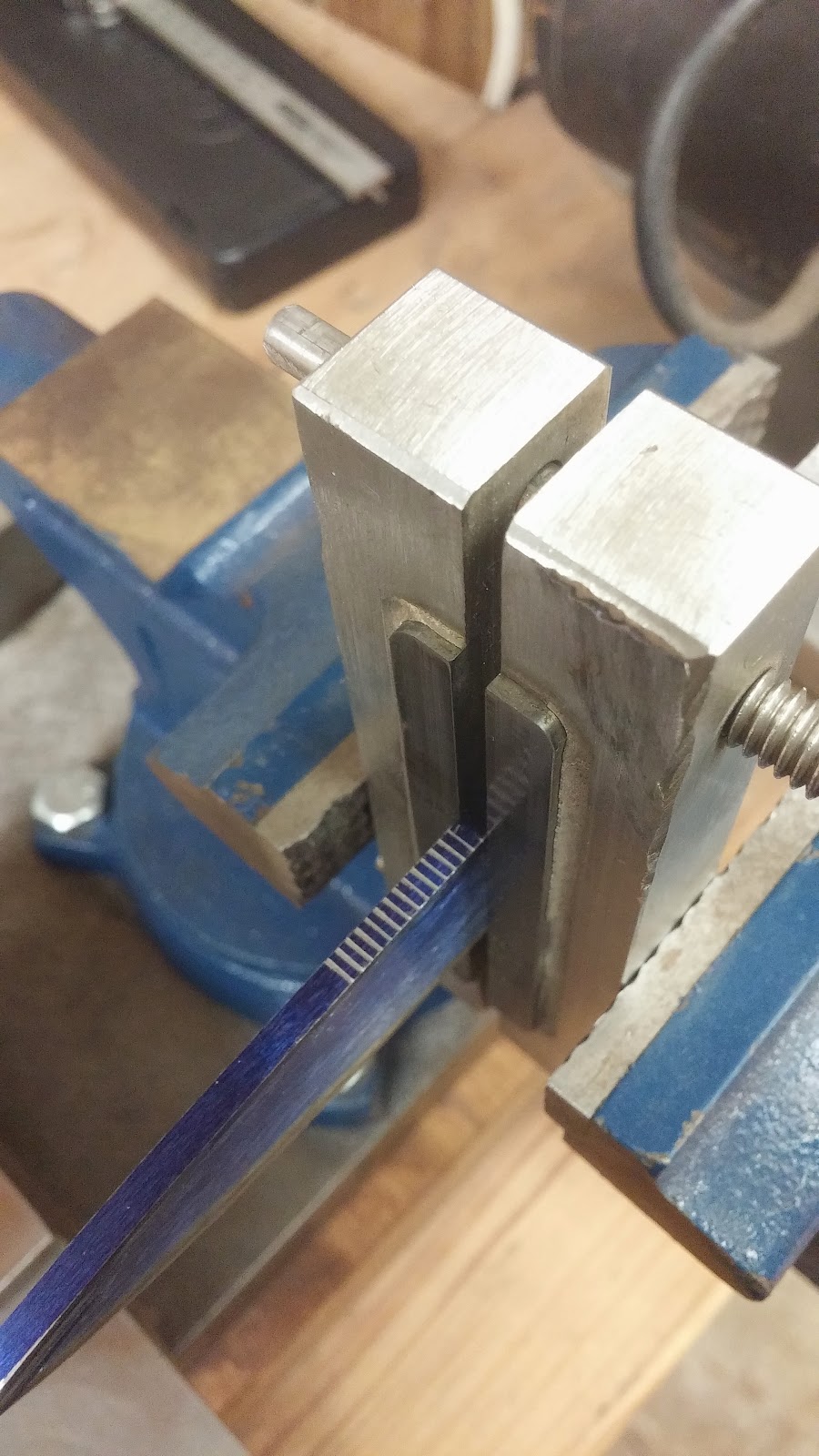

Next, I clamp the knife in the guide and square the spine to the guide with a 123 block. The guide helps me stay perpendicular to the flats and in the same spot tip to butt. Obviously the spine isn't square in this picture. I did square it before I clamped it tight.

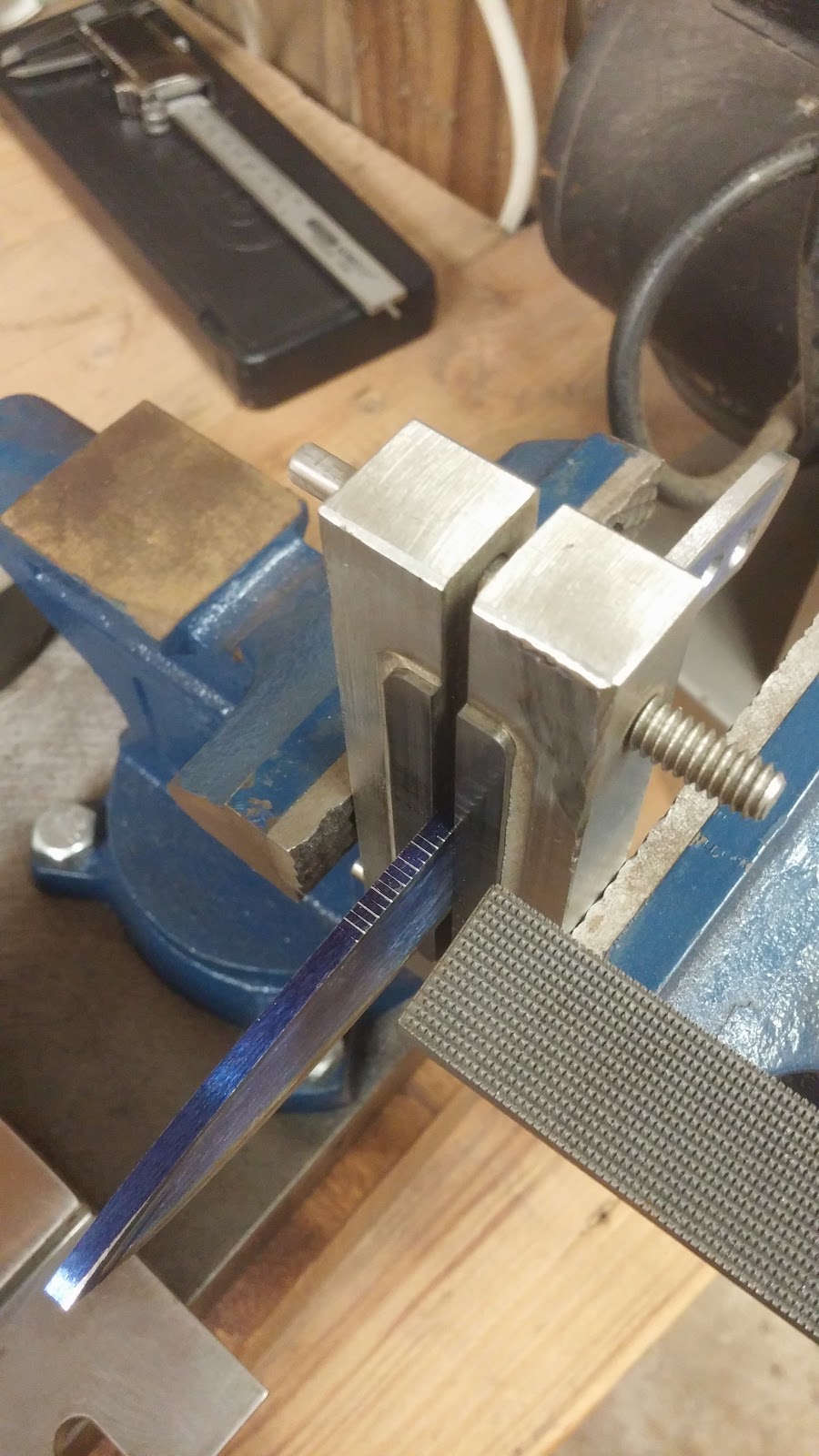

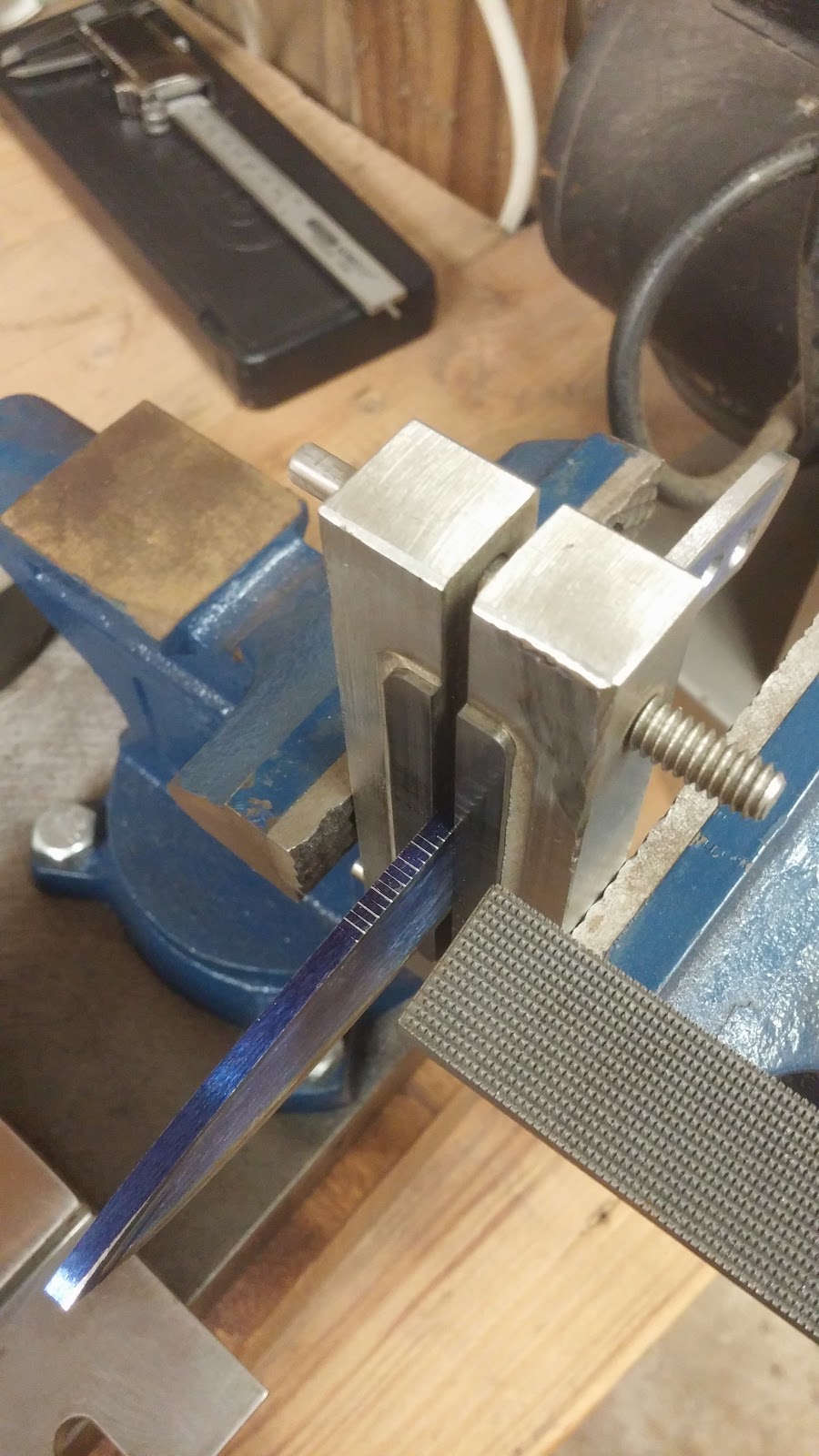

Clamp the whole thing in my vise on my steady rest station. I made the steady rests based on period and modern pictures.

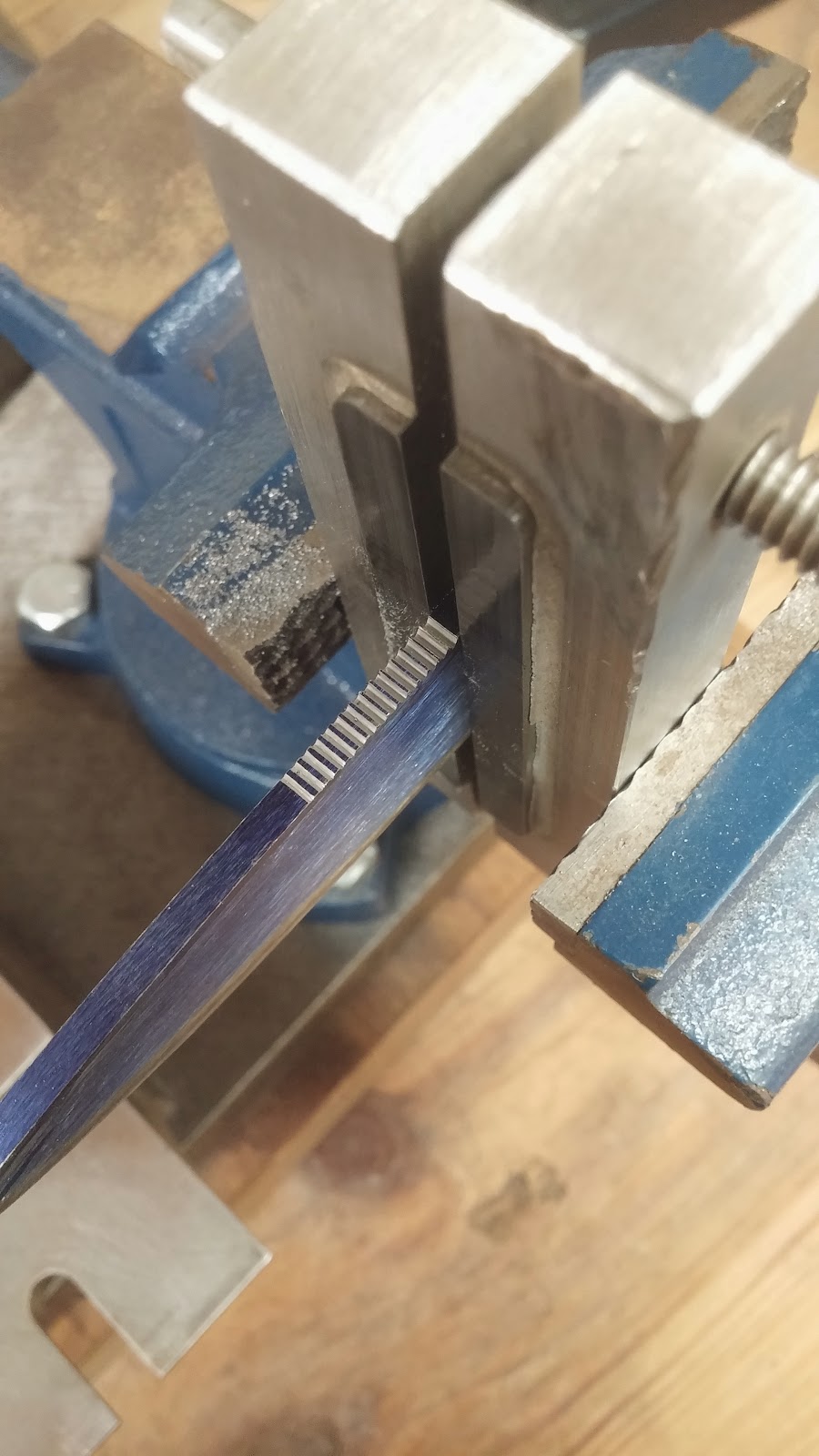

Then, I start the scratch pattern, very lightly. That is the key to the checkering file. Very light strokes at first, keeping the edge right up against the guide, the teeth of the file perpendicular to the flats, and light strokes or the teeth dig in and the pattern gets screwed up.

Checking to make sure everything is good.

Getting closer. I'm watching the dyekem on the top between the lines to make sure everything is getting narrower evenly.

Yep, that's about right, except you can see the jimping is thicker towards the tip. This means the file wasn't flat with the spine. I'll fix that in a second. The important thing is that the spacing is correct and the lines are well established.

This is a horrible picture, I know. Look at the jimping. See how it's not as deep towards the tip? Now I fix it.

Put just the bare blade into the vise this time. This is still nerve wracking for me because it's still so easy to let my focus slip just for a second and screw the whole thing up. Carefully, carefully, even out the jimping by putting more pressure on the tip side of the file and using light strokes.

Yep, that's better! Not perfect, but this is one of those "perfect is the enemy of good" situations. I fight myself a lot chasing perfection. Every single time I give in and take "just one more stroke/pass/swipe/rub" I screw something up and regret it.

Apparently I forgot to take a final picture of the spine. I'll grab one when I get home.

Anyway, that's how I jimp the spine of my Dart EDC pattern. Hope you enjoyed the pictures.

First the tools and victim. Bruce Bump carbide faced file guide and a Swiss Grobet 20 line per inch checkering file. These things both are expensive, but there is really no substitute for either. The ebony handle on the file is custom, by me. Lol. It's like holding a bar of soap, very smooth and super comfortable, which is handy when you're filing for an hour straight.

Next, I clamp the knife in the guide and square the spine to the guide with a 123 block. The guide helps me stay perpendicular to the flats and in the same spot tip to butt. Obviously the spine isn't square in this picture. I did square it before I clamped it tight.

Clamp the whole thing in my vise on my steady rest station. I made the steady rests based on period and modern pictures.

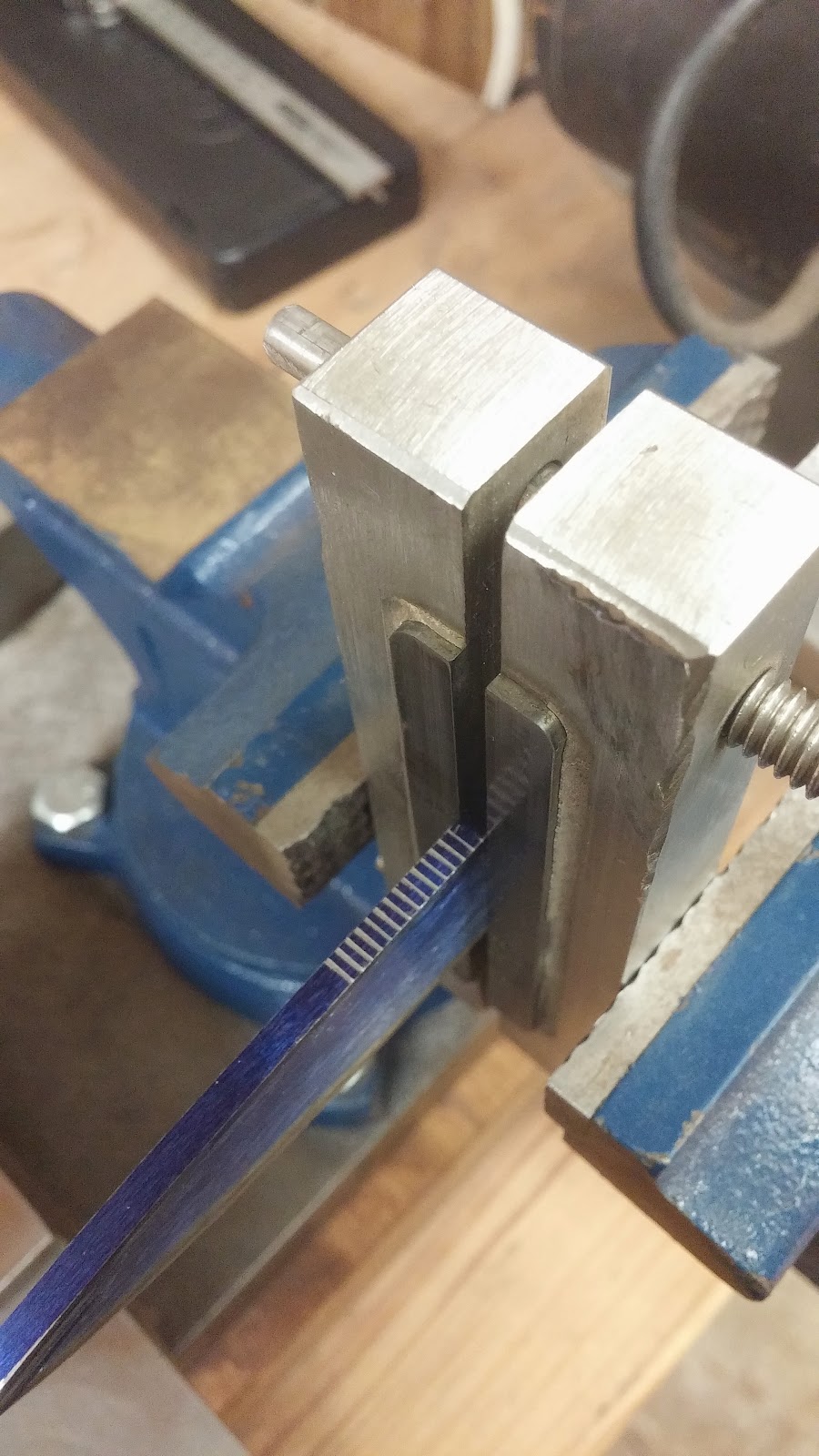

Then, I start the scratch pattern, very lightly. That is the key to the checkering file. Very light strokes at first, keeping the edge right up against the guide, the teeth of the file perpendicular to the flats, and light strokes or the teeth dig in and the pattern gets screwed up.

Checking to make sure everything is good.

Getting closer. I'm watching the dyekem on the top between the lines to make sure everything is getting narrower evenly.

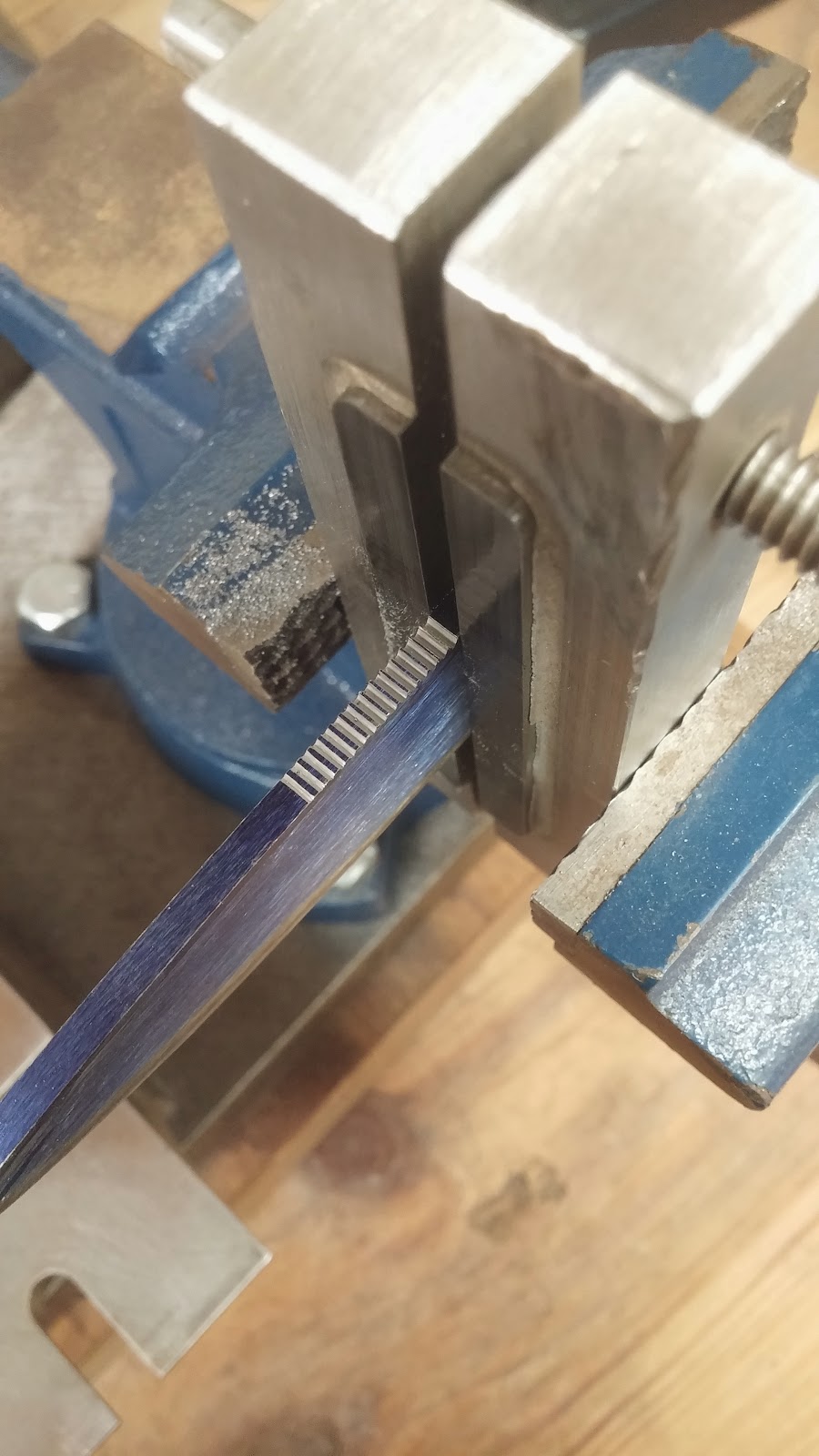

Yep, that's about right, except you can see the jimping is thicker towards the tip. This means the file wasn't flat with the spine. I'll fix that in a second. The important thing is that the spacing is correct and the lines are well established.

This is a horrible picture, I know. Look at the jimping. See how it's not as deep towards the tip? Now I fix it.

Put just the bare blade into the vise this time. This is still nerve wracking for me because it's still so easy to let my focus slip just for a second and screw the whole thing up. Carefully, carefully, even out the jimping by putting more pressure on the tip side of the file and using light strokes.

Yep, that's better! Not perfect, but this is one of those "perfect is the enemy of good" situations. I fight myself a lot chasing perfection. Every single time I give in and take "just one more stroke/pass/swipe/rub" I screw something up and regret it.

Apparently I forgot to take a final picture of the spine. I'll grab one when I get home.

Anyway, that's how I jimp the spine of my Dart EDC pattern. Hope you enjoyed the pictures.

Last edited: