Over the last couple of weeks I have thrown out some history on different threads as requested. But it is spread out and would be hard to find. I pulled that info together in this thread so that it would be easier to locate for someone doing a forum search. This info will 'help' figure out your Buck black sawcut slipjoint folding knife if it was made between 1966 and 1990.

First things first.

To be straight up accurate, Bucks first slipjoint was the 117, back in the lean-to shop days, they took surplus war lifeboat knifes and forged new clip blades to go into the handles. These are few, rare and over priced (for my pocket book anyway). Watch out for fakes....(I can only post so many photos so skipping this one)

Modern Slipjoint Production

Buck wanted to get in the slipjoint market but had no facilities to produce the knives. So it contracted out it's first slipjoint to Schrade Knives of New York beginning in 1966. Schrade produced what would later be considered a 301 sized stockman. It was not marked with a model number. This knife was a three bladed stockman with clip and sheepsfoot blade on same end and spey blade on the opposite. It can quickly be indentified by the deep grooved bolsters, slightly S shaped body, 3 brass rivet on the black sawcut Delrin* scale with the Clip blade only stamped with BUCK, Made In U.S.A. Also notice the relief grind on the top of the clip blade extends well over the finger nail groove. *

http://en.wikipedia.org/wiki/Polyoxymethylene_plastic

This is the first and only model made with grooved bolsters. Schrade went on to make two additional 301 sized models and two 303 sized stockmen.

In the photo below the identification is similar for both sized models and is represented by the larger 301 sized knife.

Left to right: First model with grooved bolster call this Version 1, next is the face of Version 2, Version 2 Schrades came in variation 1 which had NO marks on the reverse tangs of the secondary blades and variation 2 which had BUCK stamped on the reverse tang of the sheepsfoot and spey blades.

The face markings of Version 2 knives were the same. But notice that there is NO grooved bolsters.

Buck carried these well fit and finished knives for over 6 years, but a weakness became apparent and began to cost Buck time and money.

The Schrade Bucks were designed with a 'hidden pivot pin'. The ends of the blade pivot pins are not visible on the surface of the bolster. They have flat, nail like heads that are fitted into key type slots in the brass liners when the knife is assembled.

With hard and heavy use both the pin and the brass liner key-hole would fail. This can readily be seen by blades that bend pass the normal horizontal when open.

With Bucks forever warranty this led to lots of work for the repair department

In 1971 it was decided that the slipjoint contract would be move to Camillus Knife of New York and their designers used a exposed pivot pin on the bolsters which made blade repair and replacement easier. The Camillus version of the Buck slipjoint was straighter in form, had ends less rounded, gave the appearence of deep finger nic grooves and the first models had small flat scale rivets. The black sawcut scales with Bucks knife, bolt and hammer escutcheon continued.

A few Scharde made knives continued to be issued till the supply dried up later in 1971. As the transition to Camillus proceded additonal models were added. By the time full Camillus production was under way Buck was offering a 301,303,309 and 305 sized models.

Markings were similar and are represented by the 301s listed and pictured below.

Left to right:

1971, Scale rivets, Made in USA on tang, NO model number on tang, two versions - single brass scale liners and double brass liners on one side.

1971, Scale rivet, Made in USA on tang, MODEL number on reverse tang, one version - single brass scale liners

1971 - 1974, NO scale rivets, Made in USA on tang, MODEL number on revers tang, one version - single brass scale liner

1974 - 1985, No scale rivets, BUCK, 301,USA on front tang, nothing on reverse, two versions - single brass scale liners and two liners on one side.

Example of double brass liners under one scale on end. The use of extra scale liners is to 'fine tune' the 'crinking' or bend in the blade so they do not rub when folded into the blade well. (i.e. three blades, only two springs). As an example the last two knives on right show two odd-balls that issued during this era, Winchester contracted to have their name on escutcheon and because the 319 and 301 shared blades some mis-matches occurred. In this poor photo you can barely see 319 stamped in place of 301 on the tang. But sheepsfoot and spey blade in knife well, missing is leather punch to make it a real 319. The next knives in timeline after these begin actual Buck made models.

Camillus produced additional models and its relationship with Buck continued even up to the closing of factory in the mid 2000s. But Buck was making decisions which would set the course for the future.

Buck builds a slipjoint production line and begins to issue there own made models late in 1985. Buck takes over the production of the most popular models of their slipjoint knives, the 301,303,309 and 305. With the remaining models continued to be made by the Camillus factory.

Buck began by marking their knives with a date code stamp following the model number on the tang. They issued their new knives with improved 425m steel.

http://www.bladeforums.com/forums/showthread.php?t=716179

A new excutcheon plate replaced the traditional knife, bolt and hammer. The new plate simply said BUCK in capital letters. A few knives were produced in late 1985 and did not receive date code stamps, but these are rare. Between 1986 and 1988 these version of the four Buck models were heavily produced. This era was consistent and only the date code changes yearly over this period.

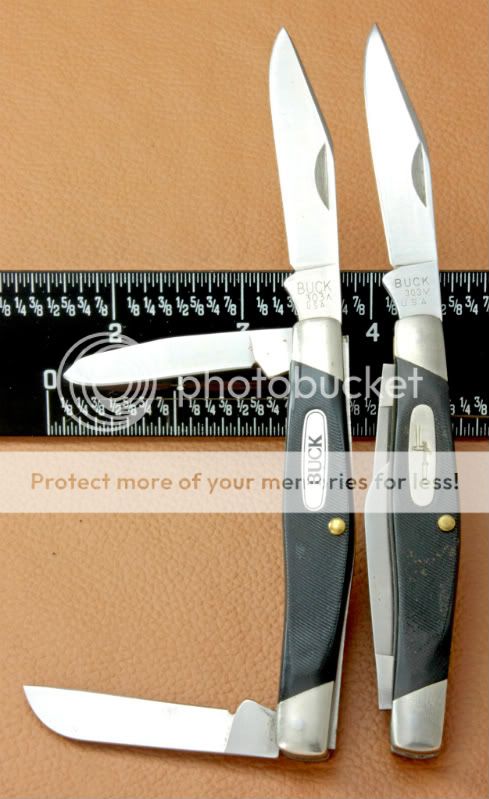

Represented here by photo of model 303s.

In 1989 after continued outcries over the escutcheon change from the knife, bolt and hammer Buck went back to the historic symbol. The newer BUCK escutcheon was also prone to have the ink quickly rub off leaving only a shallow indention of BUCK.

In late 1989 Buck designers were busy fine tuning the four models they produced. For the 1990 issue, blade steel was changed to 420HC, the knife,bolt and hammer settled in as the escutcheon plate of choice and the 303 was made with three stainless steel springs, one for each blade. Other changes were on the way in the near future. Here is the historical line-up of the 303, starting top left down and then top right down. 1966 - 1990.

After 1989 things get complicated with issues of special scale material, blade markings and changes in materials to all stainless steel occurr. That history will be written in the future.....you forumites can at least appreciate that I now am in trouble with BCCI as this posting could have been written as a newsletter article.....and may yet be.....good luck on you IDs.

300Bucks